The Specialist In Drum Handling Equipment

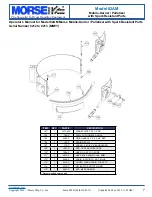

Model 82AM

Mobile-Karrier / Palletizer

with Spark Resistant Parts

Operator’s Manual for Model 82AM Morse Mobile-Karrier / Palletizer with Spark Resistant Parts

Serial number 0212 to 0213 (MMYY)

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form PL82AM (0212-0213)

(Updated 24 May, 2019 11:58 AM)

2

Safety Information

(continued)

DAnGeR

- Indicates a situation which, if not avoided, will result in serious injury or death.

This signal word is limited to the most extreme situations.

WARnInG

- Indicates a situation which, if not avoided, could result in serious injury or

death.

CAUtIOn

- Indicates a situation which, if not avoided, can result in damage to the machine.

CAUtIOn

– Do Not Transport with Drum Raised. Always lower the drum holder to lowest position

before transporting.

WARnInG

- The Mobile-Karrier / Palletizer is designed to handle one drum of the types listed at the

top of page 3. Machine Description. DO NOT attempt to handle any other type of drum or object.

DO NOT exceed the weight capacity of 600 Lb. (272 kg)

WARnInG

- Level Floors Only

For operation only on clean, level floors of suitable bearing capacity. Do not use on sloped surfaces,

ramps, irregular or debris strewn floors.

WARnInG

- Do Not Modify the Unit. Under no circumstances should any modifications be made to

the Morse machinery without factory authorization. Any modifications may void the warranty. This

machine was designed to perform a specific job and alterations may result in injury to operator or

machine.

WARnInG

- No Loose Fitting Clothing. Wear close-fitting clothing and safety equipment appropriate

to the job. Loose fitting clothing may become caught on the machinery and cause severe personal

injury.

WARnInG

- Hydraulic Fluid Under Pressure Can Be Hazardous

Escaping hydraulic fluid under pressure can penetrate the skin, causing serious injury. Avoid the

hazard by relieving pressure before disconnecting hydraulic lines. Keep hands and body away from

pinholes and nozzles, which eject fluid under high pressure. Use a piece of cardboard to search for

leaks. If an accident occurs, see a doctor immediately and inform them of the nature of the accident.

CAUtIOn

- Wear safety shoes with non-slip soles and hard toe protection.

CAUtIOn

- DO NOT allow drum to impact on floor, ground, or dumping station, etc.

WARnInG:

This product can expose you to chemicals including cobalt, titanium dioxide, and 2-methylimidazole,

which are known to the State of California to cause cancer, and bisphenol-A, which is known to the State of

California to cause birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov