The Specialist In Drum Handling Equipment

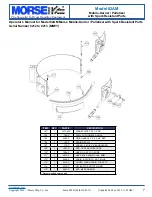

Model 82AM

Mobile-Karrier / Palletizer

with Spark Resistant Parts

Operator’s Manual for Model 82AM Morse Mobile-Karrier / Palletizer with Spark Resistant Parts

Serial number 0212 to 0213 (MMYY)

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form PL82AM (0212-0213)

(Updated 24 May, 2019 11:58 AM)

5

Operating Instructions

Roll drum lifter to drum. Steer unit so drum holder meets middle of drum. Operate

1.

hydraulics as necessary. Roll the unit forward and push drum holder so it slips around

the drum.

WARnInG:

Keep hands and other objects away from top opening of lifting frame.

To secure drum: drape cinch chain across face of drum and engage a link into notch in

2.

hub of ratchet. Pull up on ratchet handle to tighten chain. If ratchet turns to extent that

pawl is beyond last ratchet tooth and chain is not tight, back up and try putting next link

in notch. Chain should tighten as ratchet turns and be held tight by teeth of ratchet &

pawl. Firm hand pressure on ratchet handle should tension chain sufficiently to secure

drum. DO NOT use mechanical aids such as a pipe to extend ratchet handle for extra

leverage.

Operate lift function to raise drum off the floor, push drum lifter to deliver drum.

3.

Avoid unreasonably rough or non-level surfaces. Move at moderate speed. Carry

drum only high enough to avoid contact with the floor or obstacles. Push loaded unit

when possible for transporting. Pulling unit should be limited to maneuvering at short

distance.

Either one of the two spring loaded plunger tilt locks may be

4.

locked to hold drum upright. Unlocking both will permit drum

to be tilted. Drum pouring angle may be varied or drum can be

locked in horizontal position by inserting one tilt lock. It is not

necessary to lock both tilt locks. Before unlocking tilt lock it is

recommended that you steady drum and prepare to resist its

tendency to tilt toward its heavy end.

WARnInG:

Keep hands and fingers clear of tilt lock hole,

as a pinch point will occur when drum rotates.

Before unloading drum, release tilt locks and return drum to

5.

upright. Lower drum at a controlled rate.

To remove drum: pull ratchet handle clockwise to relieve

6.

pressure on ratchet teeth. Lift pawl handle to release teeth

engagement and rotate ratchet counterclockwise to loosen

chain and allow its removal from notch. Pull unit away and park

on level floor, out of traffic lanes when not in use.

Adjustment for Shorter Drums: The drum holder assembly is factory set in upper position for handling typical 55 gallon drums. For

7.

handling shorter drums such as typical 30 gallon drums, relocate drum holder assembly downward as follows: Detach by removing

nuts that hold it to lifting assembly. Reattach at alternate location 6” lower.

Maintenance

Periodic inspection for the general condition of structural and mechanical components is imperative for safe and efficient operation.

•

Periodically inspect all moving parts, framework, and contact areas for signs of wear, fatigue, or loosening. Tighten, adjust, or

•

replace parts as necessary to prevent failure and maintain proper function.

Inspect the hydraulic system for oil drips, hose damage, or other signs of wear. Inspect the level and condition of the hydraulic fluid.

•

Replace any parts that show signs of wear.

Grease wheel bearings periodically. Oil or grease all moving parts including: Tilt locks, fulcrum shafts, the hinge pin, and the ratchet

•

and pawl.

Worn or damaged parts must be properly replaced with the correct, genuine Morse parts.

•

Hydraulic pump is shipped filled with Noco Premium plus automatic transmission fluid d/m. Material safety data sheet (msds) is

•

available online. Change oil yearly, sooner depending on dirty conditions or outdoor use. Replace oil with Mobil dte 24 or equivalent

for indoor use (Mobil dte 13 for outdoor use).