7

STRAC2 Hardware Manual

920-0118 Rev B

03/26/21

Connecting Other Motors

If you do want to connect other motors , here is some information that will help

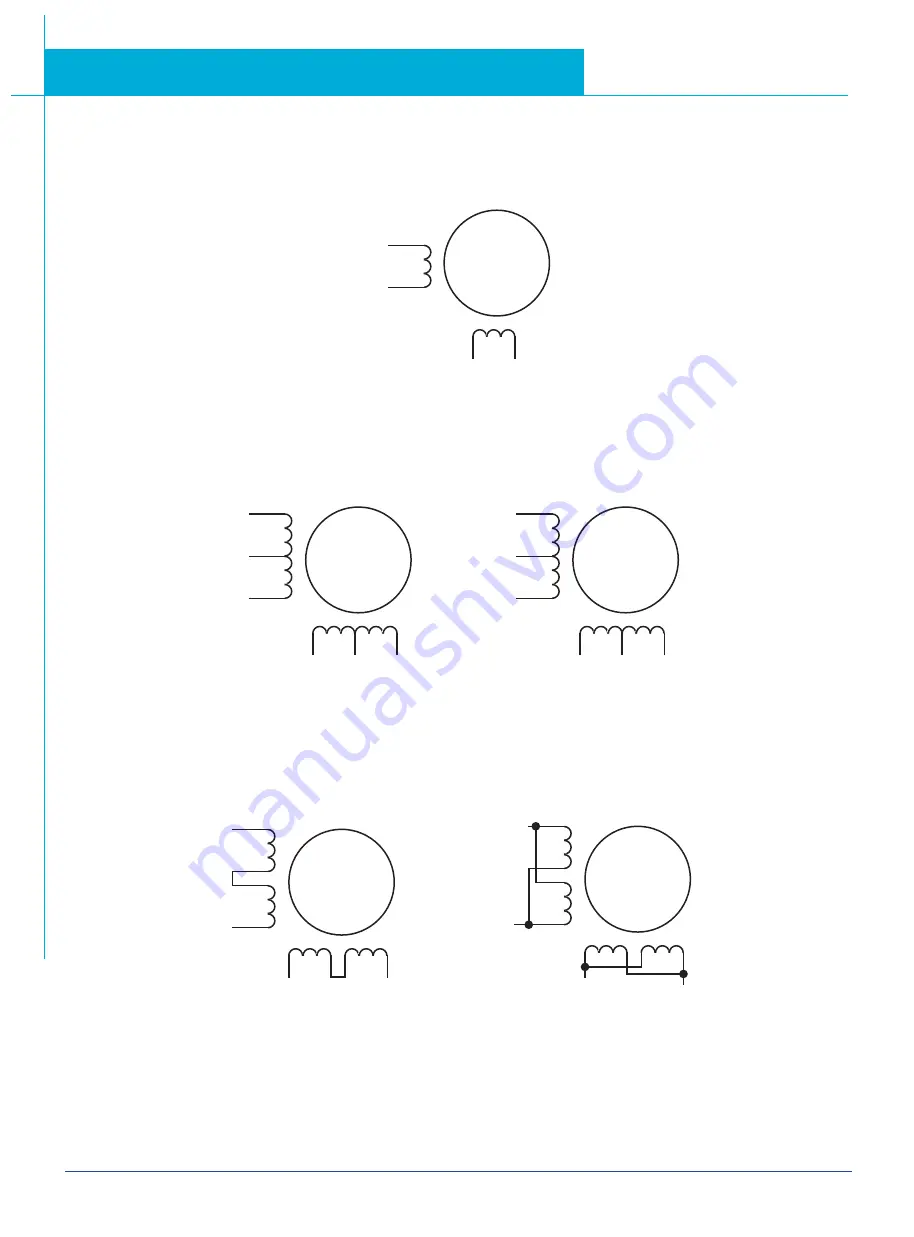

Four lead motors can only be connected one way. Please follow the sketch at the right.

A+

A–

B+

B–

4

lead

motor

Red

Blue

Yellow

White

4 Leads

Six lead motors can be connected in series or center tap. In series mode, motors produce more torque at low speeds, but cannot run as

fast as in the center tap configuration. In series operation, the motor should be operated at 30% less than the rated current to prevent

overheating. Winding diagrams for both connection methods are shown below. NC means not connected.

A+

A–

NC

B+

B–

NC

6

lead

motor

Red

Black

Red/

Wht

Green

Grn/Wht

White

A+

A–

NC

B+

B–

NC

6

lead

motor

Grn/Wht

White

Green

Red

Red/

Wht

Black

6 Leads Series Connected

6 Leads Center Tap Connected

Eight lead motors can also be connected in two ways: series and parallel. As with six lead motors, series operation gives you less torque

at high speeds, but may result in lower motor losses and less heating. In series operation, the motor should be operated at 30% less

than the unipolar rated current. The wiring diagrams for eight lead motors without shielded cables are shown below.

A+

A–

B+

B–

8

lead

motor

8 Leads Series Connected

8 Leads Parallel Connected

A+

A–

B+

B–

8

lead

motor

Orange

Org/Wht

Blk/Wht

Black

Red Red/

Wht

Yel/

Wht

Yellow

Orange

Org/

Wht

Blk/Wht

Black

Red

Red/Wht

Yel/

Wht

Yel

low