Reference 13August2014

Pg

8 of 12

Copyright 2002-2009, Monster Tower, Inc.

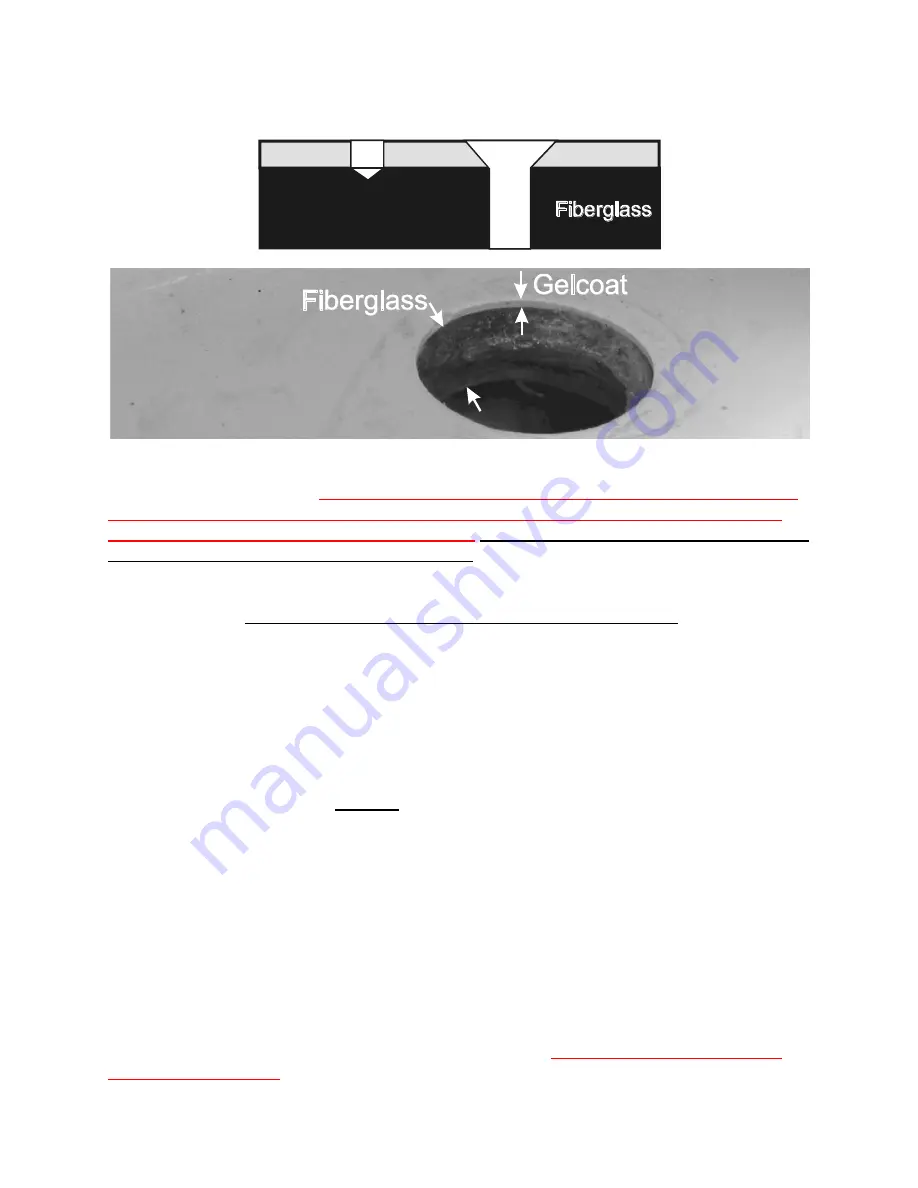

Understand the following procedures before drilling to ensure a clean hole through the

deck. Boats have a very hard gelcoat surface with fiberglass under the gelcoat as

shown below.

Gelcoat

The gelcoat is a very thin layer approximately 1/16

th

” thick and the fiberglass below it is

normally about 3/8” thick.

IMPORTANT: If the fiberglass below the gelcoat is less than

3/8” thick, you need to add fiberglass cloth and/or marine treated plywood to build up

the largest area available to at least 3/8” thick.

You need to check all mounting points as

the fiberglass thickness may vary on the boat.

You MUST run the drill in reverse while drilling the holes or the gelcoat will chip, as it is

extremely brittle. Remember to run the drill in reverse for the entire hole.

This is also a great time to have someone with a vacuum to remove the fiberglass as

you are drilling. To drill the holes use the following procedures:

1)

Begin with a 1/8” bit and run the drill in reverse until you are through the

fiberglass.

2)

Repeat the same step as above with the 5/16” bit running in reverse.

3) Finish the hole by putting a slight angle (chamfer) on the edge of the gelcoat

turning the ½” drill bit by hand (without the drill) as shown on the right side in the

above diagram to further protect the boat.

4) Using the backing plate, double check the location of the second hole for each

base and then drill the second hole using steps 1-3.

5) Confirm the two Item 1 bolts will go through the backing plate and the two holes

without binding. If needed, drill the holes to 3/8” for clearance.

6) Optionally, you can use a small piece of sand paper to radius the edge of the

chamfer also to remove the slight edge.

Next, install the rear bases (part 2), Monster Paws (part 18) - hollow section towards

boat, and backing plates (part 1) with Item 1 hardware as shown on page 9. If you are

adding wood to the underside of your deck, the wood will go between the deck and the

Monster Paw under the deck of the boat. Remember to

apply Anti-Seize to the entire

length of the M8 bolts

. Tighten these by hand; do not use a drill or pneumatic / air driver.

There is not a specific torque specification since each boat is different. Tighten the M8