20

Technical service manual

TROUBLESHOOTING

The balancing machine features autotest and autodiagnostics programs which provide in-

formation about most possible failures and the relative corrective measures (refer to the

list of error messages and the “Troubleshooting” section in the operator’s manual).

However, there are malfunctions which the machine is not able to recognise; a list of

them is provided below.

WARNING

For all electrical malfunctions, before replacing a circuit board the following should

always be checked:

- that the power supply is connected to the transformer primary correctly for the mains

voltage available.

- that the voltages of the transformer secondaries are at the specified rated values (use

a tester set as AC voltmeter and refer to the drawing of the transformer enclosed);

- that the wiring between the components probably involved in the malfunction is un-

damaged. In particular, check:

• that the connectors are fitted correctly;

• that the contacts are fixed correctly to the ends of the individual wires of the cables;

• that the mains voltage in the zone where the machine is installed is stable and that

the workshop’s earth connection system is in good working order;

• that the protective fuses on the transformer and on the power supply circuit board

have not blown, and that the LEDs on the power supply board which indicate that

the various power supply voltages are available illuminate.

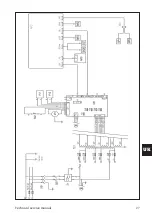

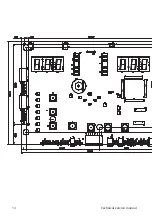

The following is a summarising table, with reference to the general electrical wiring

diagram.

THE MACHINE DOES NOT SWITCH ON

Use a voltmeter to check that the power supply voltage is reaching the terminal board

of the transformer primaries.

1) If the voltage is not present on the primaries, check:

- that the power supply socket and the relative protective fuses are in good order;

- that the plug is correctly connected to the machine’s power cord;

- that the mains power cord is undamaged;

- that the master switch is operating correctly.

2) If the voltage is present on the primaries check:

- that the transformer fuses have not blown;

- that the specified voltages are present on the transformer secondaries;

- that the power supply and PEAC control circuit board is working correctly, checking

that the fuses on the board have not blown and that the relative indicator LEDs illu-

minate;

- that the motherboard power supply cable is wired correctly and its connectors are

connected correctly;

- for short-circuits on the peripherals. To do this, disconnect all the cables from the

motherboard connectors except for the power supply cable and try to switch on the

machine;

If the checks listed above do not reveal faulty components, replace the motherboard.

Содержание MT 2450

Страница 1: ...MT 2450 Code 4 131046_uk 12 2013 Technical service manual...

Страница 25: ...Technical service manual 25 UK Note...

Страница 27: ...Technical service manual 27 UK...

Страница 28: ...28 Technical service manual...

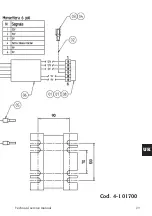

Страница 29: ...Technical service manual 29 UK Cod 4 101700...

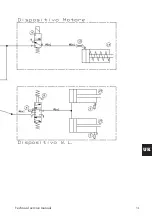

Страница 30: ...30 Technical service manual...

Страница 31: ...Technical service manual 31 UK...

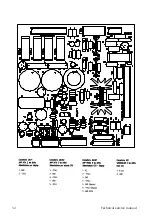

Страница 32: ...32 Technical service manual...

Страница 33: ...Technical service manual 33 UK Cod 457674B...

Страница 34: ...34 Technical service manual...

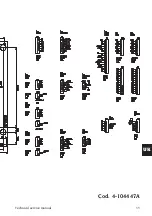

Страница 35: ...Technical service manual 35 UK Cod 4 104447A...