Hand Crimp Tool for Pitch SPOX Crimp Terminals

Doc. No: 6382819HM

Release Date: 04-25-17

UNCONTROLLED COPY

Page 2 of 7

Revision: D

Revision Date: 01-08-19

▲

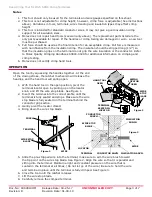

Insulation Crimp Note

Due to the terminal’s insulation grip design or insulation

diameter range, this tool uses overlap form geometry in

the insulation punch. This produces an overlap insulation

crimp (A-620-compliant). Although the insulation punch

profile may appear lopsided, this is a normal condition for

this tool. See figure to the right. Some tools with multiple

crimp pockets may not have the overlap profile on all

pockets.

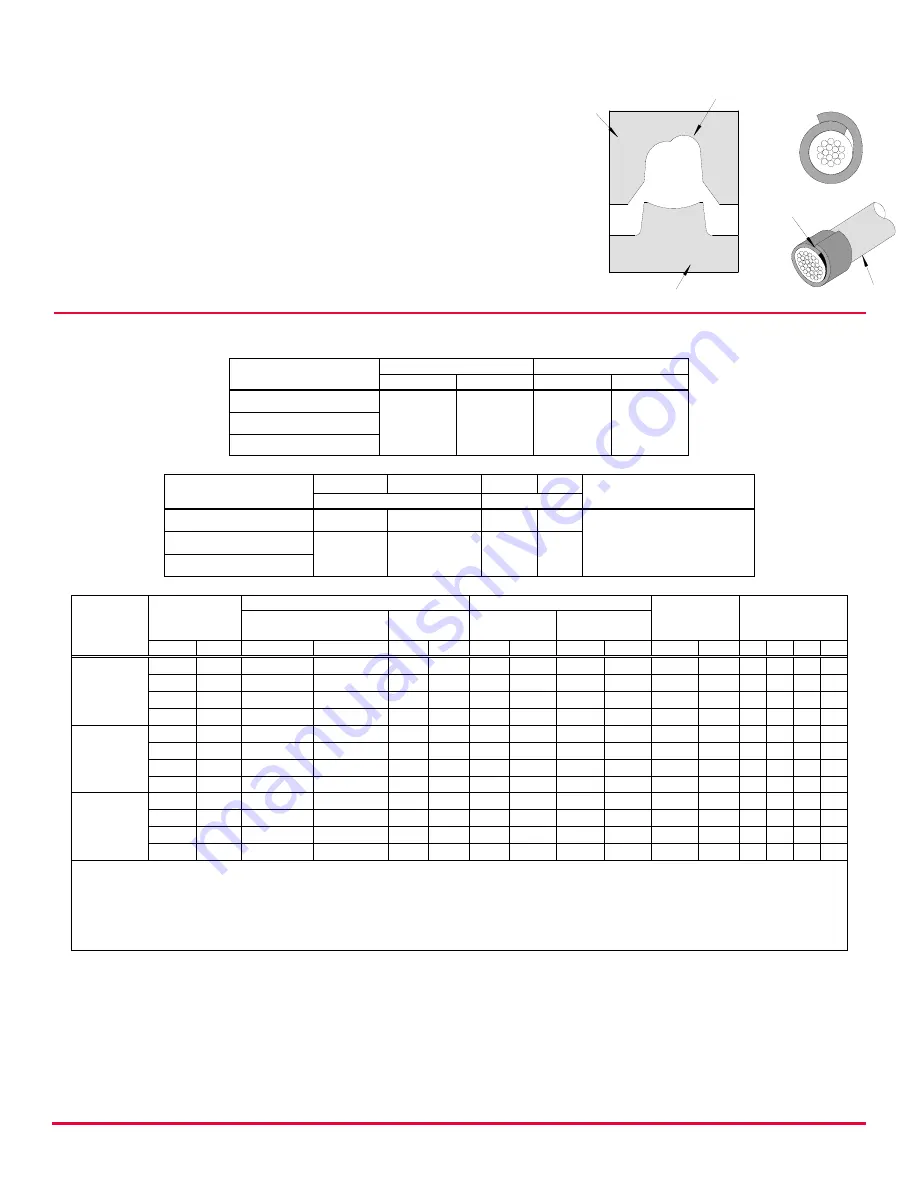

CRIMP SPECIFICATION

After crimping, the crimp profiles should measure the following:

Terminal Series No.

Bell Mouth

Conductor Brush

mm

In.

mm

In.

5103

0.20-0.50 .008-.020 0.00-1.00 .000-.039

5263

50802

Terminal Series No.

Bend Up Bend Down Twist Roll

Seam

Degree Max.

Degree Max.

5263

4

2

8

8

Seam shall not be

open and no wire allowed

out of the crimping area

5103

4

4

3

8

50802

Terminal

Series No.

Wire Size

Conductor Crimp

Insulation Crimp

Pull Force

Minimum

♦♦

Profile

Height (Ref.)

Width

(Ref.)

Height

(Ref.)

Width (Ref.)

AWG mm

2

mm

In.

mm In. mm

In.

mm

In.

N

Lb.

A B C D

5103

22

—

0.73-0.80 .029-.031 1.40 .055 1.68 .066

1.80

.071 44.48 10.0 X

24

—

0.67-0.74 .026-.029 1.40 .055 1.57 .062

1.80

.071 28.91 6.5

X

26

—

0.63-0.69 .025-.027 1.40 .055 1.42 .056

1.50

.059 17.79 4.0

X

28

—

0.61-0.67 .024-.026 1.40 .055 1.42 .056

1.50

.059 11.12 2.5

X

5263

22

—

0.73-0.80 .029-.031 1.40 .055 1.68 .066

1.80

.071 44.48 10.0 X

24

—

0.67-0.74 .026-.029 1.40 .055 1.57 .062

1.80

.071 28.91 6.5

X

26

—

0.63-0.69 .025-.027 1.40 .055 1.42 .056

1.50

.059 17.79 4.0

X

28

—

0.61-0.67 .024-.026 1.40 .055 1.42 .056

1.50

.059 11.12 2.5

X

50802

22

—

0.73-0.80 .029-.031 1.40 .055 1.68 .066

1.80

.071 44.48 10.0 X

24

—

0.67-0.84 .026-.029 1.40 .055 1.57 .062

1.80

.071 28.91 6.5

X

26

—

0.63-0.69 .025-.027 1.40 .055 1.42 .056

1.50

.059 17.79 4.0

X

28

—

0.61-0.67 .024-.026 1.40 .055 1.42 .056

1.50

.059 11.12 2.5

X

♦♦

To achieve IPC/WHMA-A-620 Class 2 crimps, the following overall wire insulation diameter ranges are

recommended:

Profile A:

1.20-1.60mm (.047-.063”)

Profile B:

1.15-1.50mm (.045-.059”)

Profile C:

1.15-1.30mm (.045-.051”)

Profile D:

1.05-1.20mm (.041-.047”)

Tool Qualification Notes

1.

Pull force should be measured with no influence from the insulation crimp.

2.

The above specifications are guidelines to an optimal crimp.

OVERLAP FORM

GEOMETRY

PUNCH

OVERLAP

INSULATION

CRIMP

WIRE

ANVIL