7

7

Before commencing commissioning:

Ensure that the electrical supply is off.

Extinguish all naked lights and open all doors and windows. D

DO

O

N

NO

OT

T S

SM

MO

OK

KE

E. Check that the gas supply is turned on at the

meter and that the main gas cock is open. Loosen the union

and allow air to be purged from the gas line until gas is

smelled. Tighten the union. See BS 6891 and/or IM 2 for further

details. Turn off the gas supply and connect a manometer to the

test point at the outlet of the combination gas control. Turn on

the gas supply. Check for gas soundness.

3

3..1

1 P

Prre

e-o

op

pe

erra

attiio

on

na

all C

Ch

he

ec

ck

ks

s

Although this unit has been assembled and fired at the factory,

the following pre-operational procedures should be performed to

ensure correct on site operation:

Check burner for alignment.

Check fan clearance. Fan should not contact casing when spun

by hand.

Check all electrical connections to ensure they are secure.

Check that all horizontal deflector blades are open a minimum of

30° as measured from vertical.

3

3..2

2 L

Liig

gh

httiin

ng

g IIn

ns

sttrru

uc

cttiio

on

ns

s

3.2.1. Set room thermostat to lowest setting

3.2.2. Drop down the bottom pan (see 4.1.1 page 8). Set gas

control knob to PILOT and push in while lighting the pilot

with gas match or taper.

Hold in for 1/2 minute after pilot is lit.

3.2.3. Check pilot flame adjustment. The pilot burner is fitted with

an injector such that it will operate correctly with an inlet

pressure of 15-20 mbar on natural gas and 37mbar on

propane but final adjustment must be made after

installation. Adjust to have a soft steady flame 20-25mm

long and encompassing 8 to 12mm of the tip of the

thermocouple. Normally this flame will produce satisfactory

results. To adjust flame use the pilot adjustment screw on

combination gas control (for location, see Figure 4).

If the pilot flame is longer and larger than shown by Figure

5 it is possible that this will cause soot and/or impinge on

the heat exchanger causing burnout. If the pilot flame is

shorter than shown it may cause poor ignition and result in

the controls not opening the combination gas control. A

short flame can be caused by a dirty pilot injector. Pilot

flame condition should be observed periodically to ensure

trouble free operation.

3.2.4. Move gas control knob to ON.

3.2.5. Set room thermostat to desired setting.

3.2.6. Check gas piping for leaks as described in IM 5.

3.2.7. Check gas input rate by measuring burner pressure using

the manometer fitted to test point at the outlet of the

combination gas control. Allow unit to operate for 15

minutes to stabilize. Check the pressure and if necessary

adjust to the figure shown in Table 2 on page 4 for the

particular model. The location of the pressure setting

adjuster on the combination gas is shown in Figure 4.

Remove the dust cover over the adjuster and, using a

small screwdriver turn the screw beneath clockwise to

increase and anti-clockwise to decrease the pressure.

Allow the unit to operate for 15 minutes then check the

pressure again. Replace the dust cover when finished.

Disconnect the manometer from the test point and replace

the sealing screw in the pressure test nipple.

3

3..3

3 C

Co

on

nttrro

oll O

Op

pe

erra

attiin

ng

g S

Se

eq

qu

ue

en

nc

ce

e

With pilot alight, when the thermostat calls for heat, power is

supplied to the combination gas control and at the same time

power is supplied to the fan timer. The main burner should light

immediately. The fan motor will start in 15 to 45 seconds. When

the thermostat has been satisfied, power is turned off to the

combination gas control and fan timer. The main burner will go

out but the pilot will continue to burn. The fan motor will continue

to operate for 45 to 75 seconds to allow the heat exchanger to

cool down.

F

Fiig

gu

urre

e 5

5

P

Piillo

ott F

Flla

am

me

e A

Ad

djju

us

sttm

me

en

ntt

3

3.. C

CO

OM

MM

MIIS

SS

SIIO

ON

NIIN

NG

G

F

Fiig

gu

urre

e 4

4

C

Co

om

mb

biin

na

attiio

on

n G

Ga

as

s C

Co

on

nttrro

oll

20/25mm

CAUTION

Start-up and adjustment procedures should be performed by

a qualified engineer.

!

CAUTION

Important – Supply pressure and setting pressure must be

checked with heater in operation when making final adjustments.

!

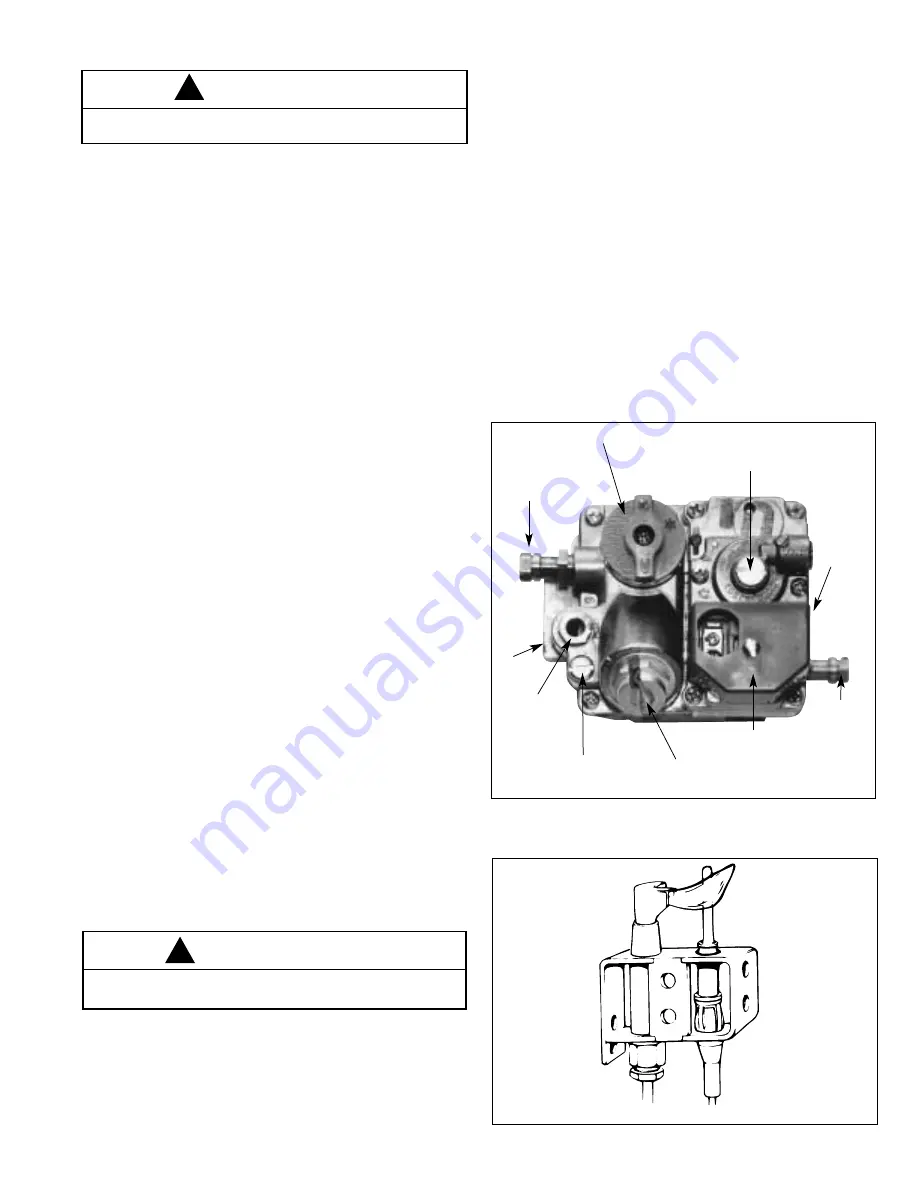

GAS CONTROL KNOB

INLET PRESSURE

TEST FITTING

PRESSURE REGULATOR

ADJUSTMENT SCREW

(UNDER CAP SCREW)

INLET

PILOT TUBING

PILOT ADJUSTMENT

SCREW

THERMOCOUPLE / INTERRUPTER

CONNECTION

PROTECTIVE COVER

OUTLET

OUTLET

PRESSURE

TEST

FITTING