MMP SA-2550A

Page 12 of

24

Midwest Motion Products

DESIGN, MANUFACTURING & DISTRIBUTION - MOTION CONTROL EQUIPMENT

email:

How to reverse a brushless DC motor

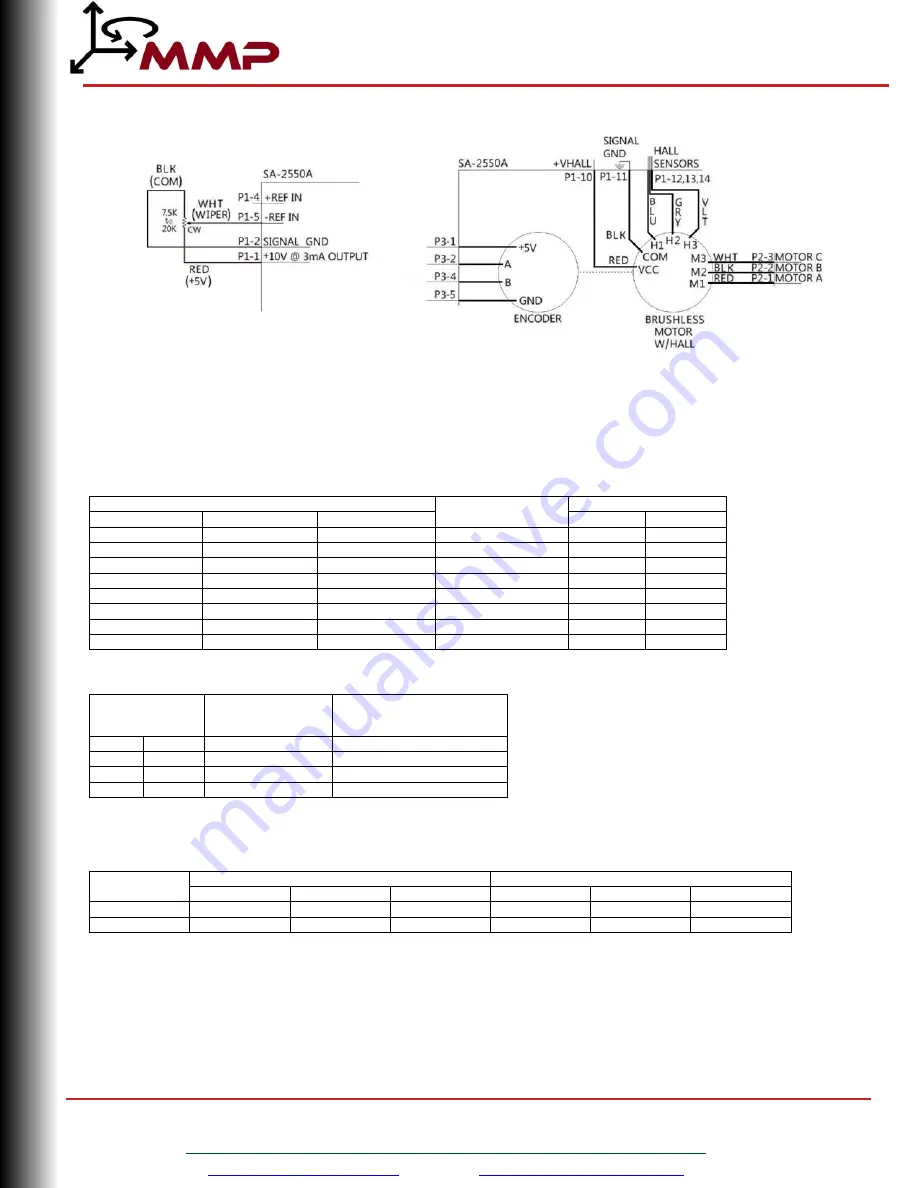

Figure 2. Typical Wiring Solution of a Brushless Motor with Encoder.

The typical wiring solution shown above results in the brushless motor to run forward (CW rotation) with the potentiometer max at

the CW position. Methods to reverse the brushless motor direction via wiring are as follows:

-

Change the wiring connections of the potentiometer or jump leads. There are many ways to wire a potentiometer to the

servo amplifier or jump the potentiometer leads. Consult the tables below for what leads to connect to which pins.

Potentiometer Wiring Solutions

Connect Potentiometer Leads to Pins

Motor Direction

of Rotation*

Potentiometer

RED (+5V)

BLK (GND)

WHT (WIPER)

Range

Rotation

P1-1

P1-2

P1-5

FWD

0-100%

CW

P1-3

P1-2

P1-4

FWD

0-100%

CW

P1-1

P1-2

P1-4

REV

0-100%

CW

P1-3

P1-2

P1-5

REV

0-100%

CW

P1-2

P1-3

P1-4

FWD

100-0%

CCW

P1-2

P1-1

P1-5

FWD

100-0%

CCW

P1-2

P1-1

P1-4

REV

100-0%

CCW

P1-2

P1-3

P1-5

REV

100-0%

CCW

*Assumes that Hall Sensors and Motor Leads are wired in accordance with the above diagram.

Wire without Potentiometer (direct pin connections)

Connect Leads

Motor Direction

of Rotation*

Simulated

Potentiometer Output

P1-1

P1-5

FWD

100%

P1-3

P1-4

FWD

100%

P1-1

P1-4

REV

100%

P1-3

P1-5

REV

100%

*Assumes that Hall Sensors and Motor Leads are wired in accordance with the above diagram.

-

Change Motor and Hall Sensor Leads. To reverse motor direction, consult the below table to properly change motor and hall

sensor leads.

Motor

Direction

Hall Sensor Connection to Drive

Motor Connection to Drive

H1 (BLU)

H2 (GRY)

H3 (VLT)

M1 (RED)

M2 (BLK)

M3 (WHT)

FWD

P1-12

P1-13

P1-14

P2-1

P2-2

P2-3

REV

P1-14

P1-13

P1-12

P2-2

P2-1

P2-3

WARNING : DO NOT reverse the servo amplifier input power leads, HV (P2-5) and GND (P2-4) to reverse the direction of motor

rotation. This can cause severe, irreversible damage to the servo amplifier.

MIDWEST M

O

TION

P

RODUCTS