Technical Documentation

ZRF-P 2040

mk North America, Inc.

|

105 Highland Park Drive

|

Bloomfi eld, CT 06002

|

(860) 769-5500

|

www.mknorthamerica.com

©2022

|

Page 22

mk North America, Inc.

|

105 Highland Park Drive

|

Bloomfi eld, CT 06002

|

(860) 769-5500

|

www.mknorthamerica.com

©2022

|

Page 23

8

CONVEYOR BELT MAINTENANCE - BELT REPLACEMENT

8.1 Standard Idler

19

General Remarks:

• Prior to replacing the belt, the tail assembly must be completely loosened and retracted – instructions for

this to follow.

• Any auxiliary parts that interfere must be removed.

• One side of the conveyor must be free and clear of all interferences. THIS IS BEST DONE ON THE SIDE

WITHOUT THE MOTOR MOUNT.

• Reassemble in reverse order.

• Replacement belts must be tracked and tensioned prior to use. (see Section 7)

All work to be performed by qualifi ed personnel only.

Conveyor power must be disconnected before replacing the belt.

8

CONVEYOR BELT MAINTENANCE - BELT REPLACEMENT

(CONT.)

8.1 Standard Idler

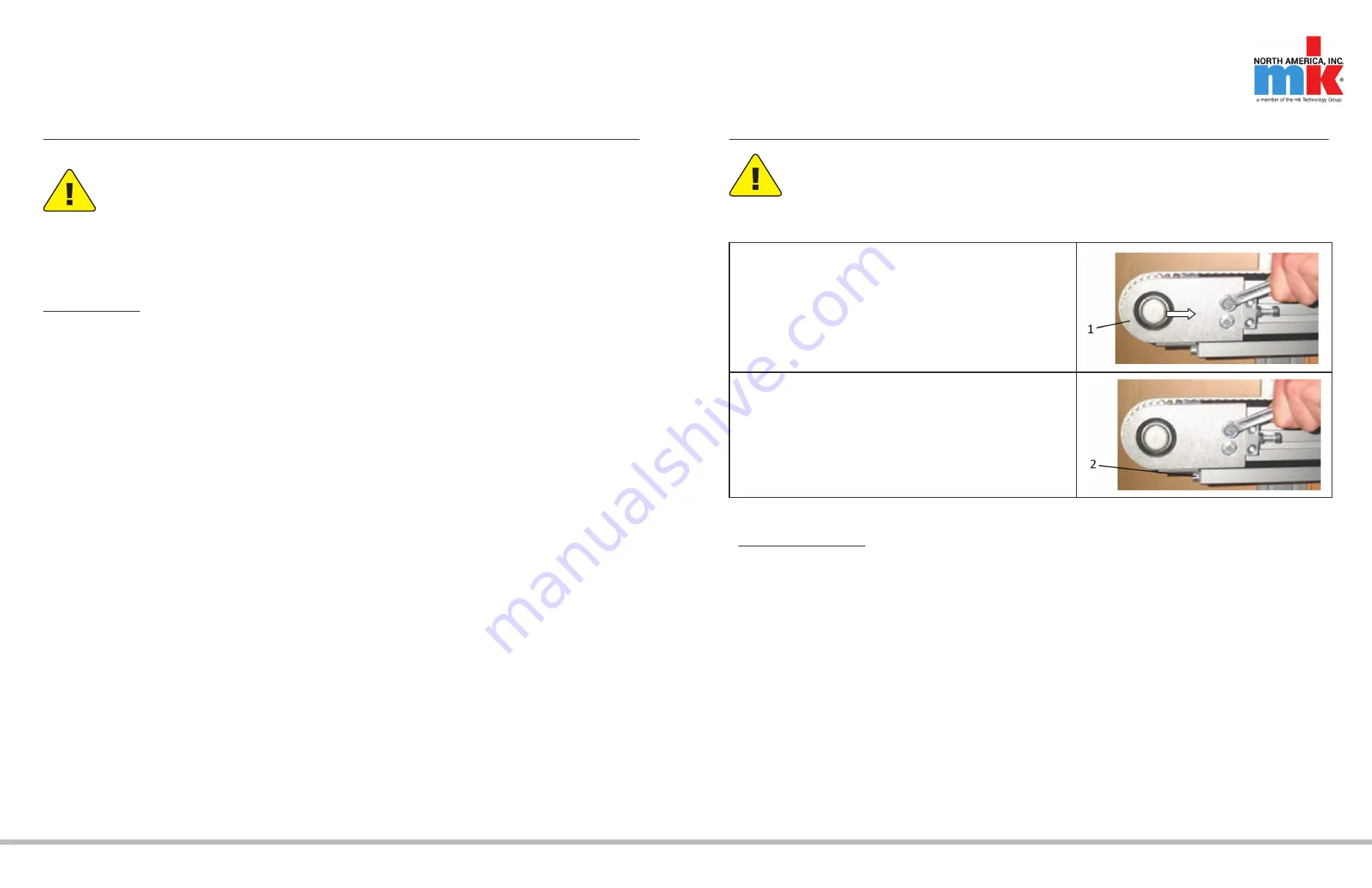

Loosen all bolts and push the entire head (1) inwards (in

the direction of the arrow), in order to create slack in the

timing belt.

Additional Instructions:

• The belt can now be replaced once all auxiliary obstructions are removed.

• Slide the existing belt off the free side of the conveyor frame.

• To replace belt, slip it over the side of the conveyor.

• Reassemble conveyor in the reverse order and the track and tension belt prior to use. (see Section 7)

All work to be performed by qualifi ed personnel only.

Conveyor power must be disconnected before replacing the belt.