Technical Documentation

ZRF-P 2040

mk North America, Inc.

|

105 Highland Park Drive

|

Bloomfi eld, CT 06002

|

(860) 769-5500

|

www.mknorthamerica.com

©2022

|

Page 20

mk North America, Inc.

|

105 Highland Park Drive

|

Bloomfi eld, CT 06002

|

(860) 769-5500

|

www.mknorthamerica.com

©2022

|

Page 21

7

CONVEYOR BELT MAINTENANCE - TENSIONING & TRACKING

7.1 Standard Idler

17

General Remarks:

• Belts may need to be tracked due to shifting during shipping.

• Prior to delivery of the mk conveyor, the belt was tensioned and tracked at the factory.

• Belt tracking should only be done at the idler end.

• Avoid over tensioning the belt, increase slack in belt if necessary.

All work to be performed by qualifi ed personnel only.

Conveyor power must be disconnected before replacing the belt.

7

CONVEYOR BELT MAINTENANCE - TENSIONING & TRACKING

(CONT.)

7.1

Standard Idler

All work to be performed by qualifi ed personnel only.

Conveyor power must be disconnected before replacing the belt.

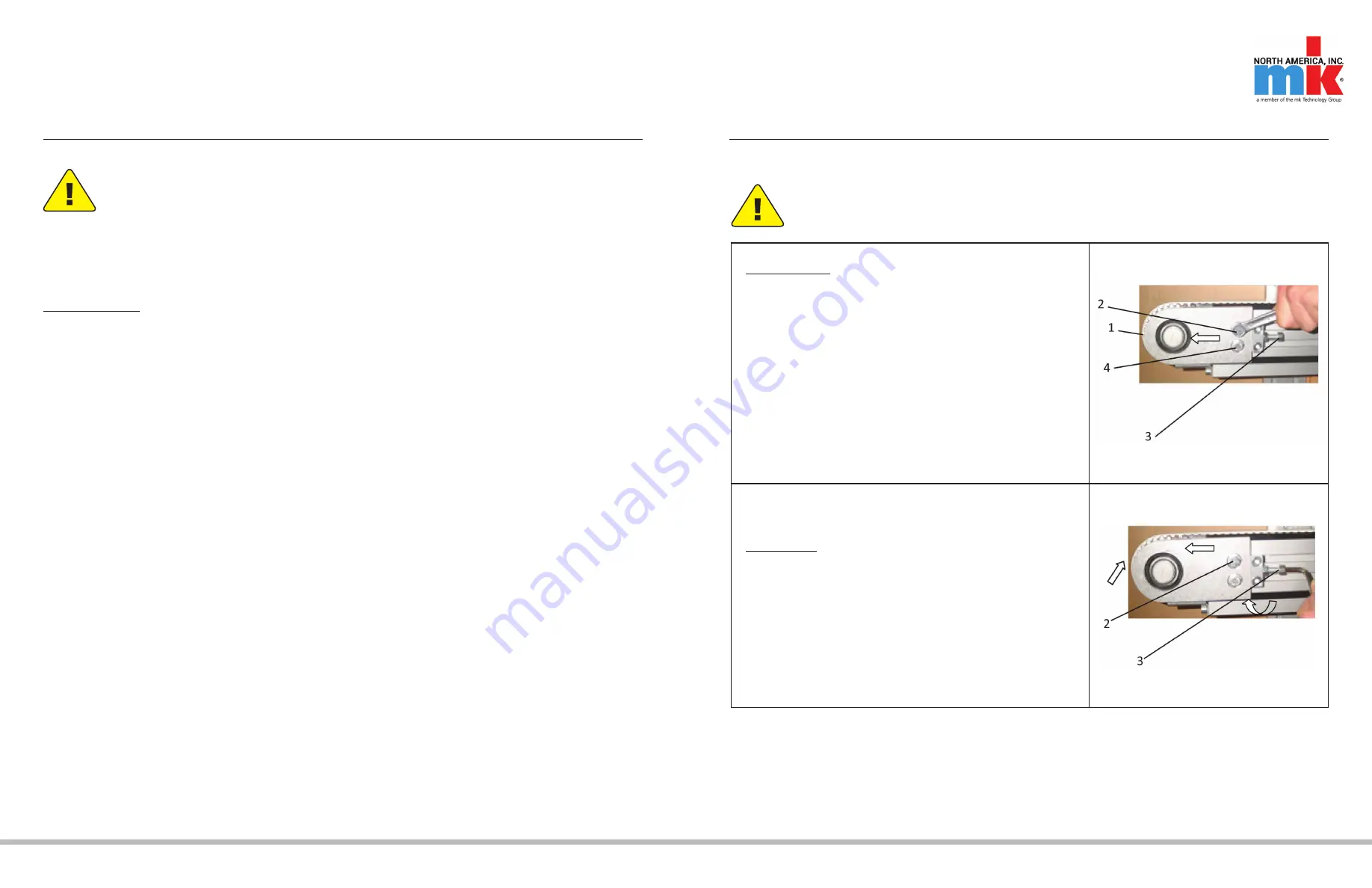

Belt Tensioning

Caution!

Belt tensioning is only to be done at the idler end (opposite the

motor end).

General Instructions:

• The belt was tensioned and adjusted at the factory before

delivery of the mk product.

Loosen screws (2) and (4) to pull the entire assembly (1)

out (arrow direction) in order to pretension the timing belt.

Tighten screw (4) and then fi nally adjust the timing belt with

screw (3), see below.

Tighten bolt (2).

Belt Tracking

Caution!

Tracking (or realignment) of the belt must only be done while

the belt is moving (pinch points).

Adjust bolt (2) and screw (3) in the direction of the arrow, for

the fi ne adjustment to the timing belt until the belt is running

centrally on the pulley. Tighten the bolt (2).