20

9-2. Unit replacement operation

When reusing the existing pipes that carried R22 refrigerant for the SW75/100/120 models, replacement operation

must be performed before performing a test run.

1

If new pipes are used, these procedures are not necessary.

2

If existing pipes that carried R22 refrigerant are used for the SW75/100/120 models, these procedures are not necessary.

(The replacement operation cannot be performed.)

3

During replacement operation, “C5” is displayed on “A-Control Service Tool (PAC-SK52ST)”. (This is applied to only

SW75/100/120 models.)

9-1. Refrigerant collecting (pump down)

Perform the following procedures to collect the refrigerant when moving the indoor unit or the outdoor unit.

1

Supply power (circuit breaker).

*

When power is supplied, make sure that “CENTRALLY CONTROLLED” is not displayed on the remote controller. If “CEN-

TRALLY CONTROLLED” is displayed, the refrigerant collecting (pump down) cannot be completed normally.

*

Start-up of the indoor-outdoor communication takes about 3 minutes after the power (circuit breaker) is turned on. Start the

pump-down operation 3 to 4 minutes after the power (circuit breaker) is turned ON.

*

In the case of multi-units control, before powering on, disconnect the wiring between the master indoor unit and the slave

indoor unit. For more details refer to the installation manual for the indoor unit.

2

After the liquid stop valve is closed, set the SWP switch on the control board of the outdoor unit to ON. The compressor

(outdoor unit) and ventilators (indoor and outdoor units) start operating and refrigerant collecting operation begins. LED1

and LED2 on the control board of the outdoor unit are lit.

*

Only set the SWP switch (push-button type) to ON if the unit is stopped. However, even if the unit is stopped and the

SWP switch is set to ON less than 3 minutes after the compressor stops, the refrigerant collecting operation cannot be per-

formed. Wait until compressor has been stopped for 3 minutes and then set the SWP switch to ON again.

3

Because the unit automatically stops in about 2 to 3 minutes when the refrigerant collecting operation is completed (LED1

off, LED2 lit), be sure to quickly close the gas stop valve. If LED1 is lit and LED2 is off and the outdoor unit is stopped,

refrigerant collection is not properly performed. Open the liquid stop valve completely, and then repeat step

2

after 3 min-

utes have passed.

*

If the refrigerant collecting operation has been completed normally (LED1 off, LED2 lit), the unit will remain stopped until the

power supply is turned off.

4

Turn off the power supply (circuit breaker).

* Note that when the extension piping is very long with large refrigerant amount, it may not be possible to perform a pump-

down operation. When performing the pump-down operation, make sure that the low pressure is lowered to near 0 MPa

(gauge).

Warning:

When pumping down the refrigerant, stop the compressor before disconnecting the refrigerant pipes. The compressor

may burst if air etc. get into it.

9-3. Start and finish of test run

•

Operation from the indoor unit

Execute the test run using the installation manual for the indoor unit.

•

Operation from the outdoor unit

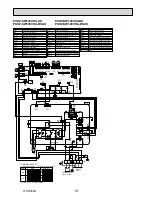

By using the DIP switch SW4 on the control board of outdoor unit, test run can be started and finished, and its operation

mode (cooling/heating) can be set up.

1

Set the operation mode (cooling/heating) using SW4-2.

2

Turn on SW4-1 to start test run with the operation mode set by SW4-2.

3

Turn off SW4-1 to finish the test run.

•

There may be a faint knocking sound around the machine room after power is supplied, but this is

no problem with product because the linear expansion pipe is just moving to adjust opening pulse.

•

There may be a knocking sound around the machine room for several seconds after compressor

starts operating, but this is no problem with product because the check valve itself, generates the

sound because pressure difference is small in the refrigerant circuit.

Note:

The operation mode cannot be changed by SW4-2 during test run. (To change test run mode, stop the unit by SW4-1,

change the operation mode and restart the test run by SW4-1.)

OFF

1

2

ON

<SW4>

Stop

Operation

Cooling

Heating

OCH533A