20

CLEANING

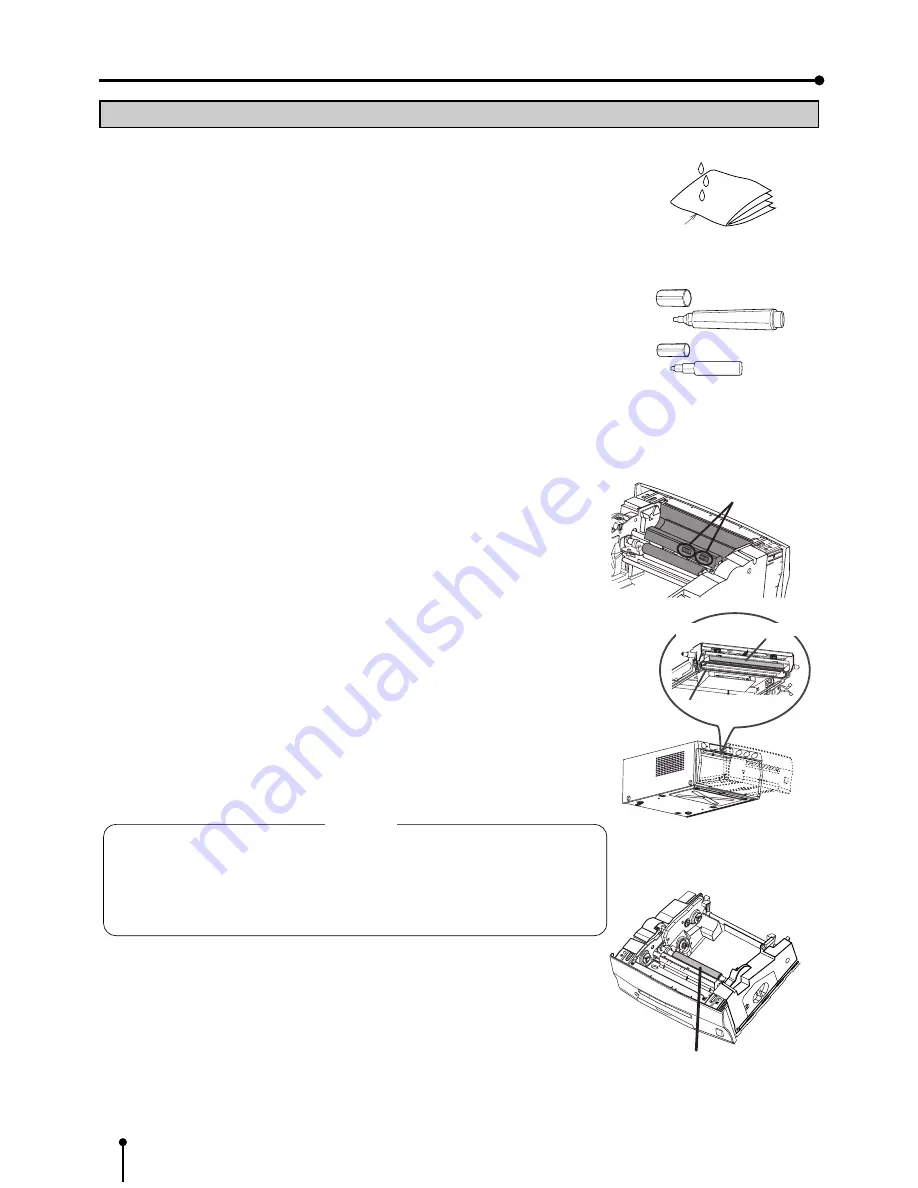

Cleaning part

A small amount of alcohol

How to hold tissue paper

Cleaner pen (Option)

Ink sheet sensor

Front panel

Rubber roller

Cleaning as indicated below will help maintain stable printer operation and extend the

printer’s life.

Preparations

Alcohol (isopropyl alcohol)

Tissue paper (Fold in half about 4 times, and use the folded side to clean.)

Cotton buds

Cleaning kit (Option)*

Other : Cleaner pen (Option)*

*Please ask the dealer about options.

Make sure to turn off the power before cleaning.

1

1

1

1

1

Press OPEN button to pull the printing mechanism out.

2

2

2

2

2

Remove the ink cassette and print paper.

3

3

3

3

3

Wipe the ink sheet sensor.

Clean the parts circled in the right figure.

Carefully wipe with tissue paper etc. which is soaked in a small amount of alcohol.

4

4

4

4

4

Wipe the ink sheet sensor reflection plate.

Clean the metal reflection plate.

Carefully wipe with tissue paper etc. which is soaked in a small amount of alcohol.

5

5

5

5

5

Wipe the head.

Cleaning the part under the thermal head which develops heat.

Wipe the head cleaning part carefully with tissue paper etc. which is soaked in a

small amount of alcohol.

NOTE

•

Do not damage the thermal head.

•

When the symptom of the poor print quality is not corrected even if the head is

cleaned, replacing the thermal head is required. Contact your dealer.

•

Thermal head is hot right after printing. Wait until the head cools before cleaning

the thermal head.

6

6

6

6

6

Clean the rubber roller.

Dust etc. can build up on the rubber roller after prolonged use. Carefully wipe with

tissue paper etc. which is soaked in a small amount of alcohol.

Ink sheet sensor reflection plate

Thermal head

CLEANING