Chapter 5 Options

5–13

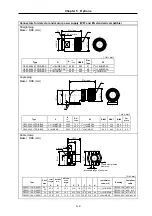

5-2 Manufacturing the cable

5-2-1 Manufacturing the power supply cable

(1) Selecting the wire size

As shown below, select the size of the wire for the power supply cable used between the amplifier

and motor using the servo amplifier capacity as a reference regardless of the motor type and motor

capacity.

MDS-B-V1-

05

10

20

35

45

70

90

Servo

amplifier

capacity

MDS-B-SVJ2-

06

10

20

−

−

−

−

Recommended wire size

IV2SQ

or

HIV2SQ

IV2SQ

or

HIV2SQ

IV3.5SQ

or

HIV2SQ

IV5.5SQ

or

HIV3.5SQ

IV5.5SQ

or

HIV3.5SQ

IV8SQ

or

HIV5.5SQ

IV8SQ

or

HIV8SQ

(2) Assembling the cable

Manufacture the cable according to the specifications (terminal block, etc.) of the servo amplifier

actually being used.

5-2-2 Manufacturing the detector cable

(1) Cable wire

Manufacture the cable using the recommended wire or equivalent parts as shown below.

Wire characteristics

Recommended wire type

(Cannot be directly

ordered from Mitsubishi

Electric Corp.)

Finished

outside

diameter

Sheath

material

No. of

pairs

Config-

uration

Conductor

resistance

Withstand

voltage

Insulation

resistance

A14B2343 (Note)

7.2mm

PVC

6

14 strands/

0.08mm

105

Ω

/km

or less

AC500/

1min

1500M

Ω

/km

or more

(Note)

Junko Co. (Dealer: Toa Denki)

(2) Cable assembly

Assemble the cable as shown in the following drawing, with the cable shield wire securely

connected to the ground plate of the connector.

Ground plate

Sheath

Shield (external conductor)

Core wire

Sheath

Shield

(external conductor)

Core wire