Chapter 3 Precautions for Use

3–6

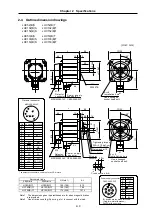

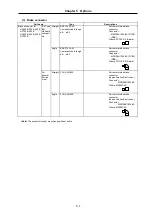

3-2-3 Tolerable load of axis

There is a limit to the load that can be applied on the shaft. Make sure that the load applied in the radial

direction and thrust direction, when mounted on the machine, is below the tolerable values given below.

These loads also affect the motor output torque, so consider them when designing the machine.

Servomotor

Tolerable radial load

Tolerable thrust load

HC52T, 102T, 152T

HC53T, 103T, 153T

Tapered shaft

392N (40kgf),

L=58

490N (50kgf)

HC52S, 102S, 152S

HC53S, 103S, 153S

Straight shaft

980N (100kgf), L=55

490N (50kgf)

HC202S, 352S, 452S,702S

HC203S, 353S, 453S, 703S

2058N (210kgf), L=79

980N (100kgf)

HC902S

2450N (250kgf), L=85

980N (100kgf)

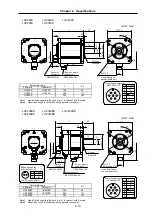

HC103RT, 153RT, 203RT

Tapered shaft

392N (40kgf),

L=58

196N (20kgf)

HC103RS, 153RS, 203RS

Straight shaft

686N (70kgf),

L=45

196N (20kgf)

HA353RS, 503RS

980N (100kgf), L=63

392N (40kgf)

Caution:

The symbols in the table follow the drawing below.

L

Thrust load

Radial load

L : Length from flange installation surface to center of load weight [mm]

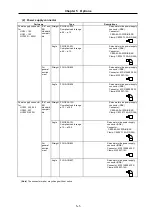

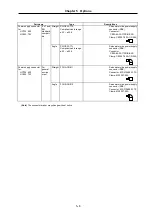

CAUTION

1. When coupling with a ball screw, etc., use a flexible coupling, and keep the

shaft core deviation to below the tolerable radial load.

2. When directly installing the gears on the motor shaft, the radial load will

increase as the gear diameter decreases. Consider this when designing the

machine.

3. When directly installing a pulley on the motor shaft, make sure that the radial

load (double the tension) generated from the timing belt tension is less than

the values in the above table.

4. In a machine having a thrust load, such as a worm gear, provide a separate

bearing on the machine side so that the a load exceeding the tolerable thrust

load is not applied on the motor.

5. Do not use a rigid coupling as an excessive bending load will be applied on

the shaft and could cause the shaft to break.