22

GB

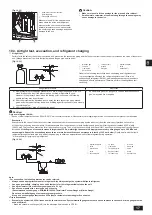

Example of a group operation system with multiple outdoor units (Shielding wires and address setting are

necessary.)

<Examples of transmission cable wiring>

[Fig. 11.3.1] ME Remote Controller

A

D

E

B

C

<A> Change the jumper connector

from CN41 to CN40 *1

<B> SW5-1: ON *2

<C> Keep the jumper connector on

CN41

<B> SW5-1: ON *2

System

controller

*1 : When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply connector (CN41) from ONE

outdoor unit in the system and connect it to CN40.

*2 : If a system controller is used, set SW5-1 on all of the outdoor units to ON.

[Fig. 11.3.2] MA Remote Controller

A

D

E

B

C

<A> Change the jumper connector

from CN41 to CN40 *1

<B> SW5-1: ON *2

<C> Keep the jumper connector on

CN41

<B> SW5-1: ON *2

System

controller

*1 : When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply connector (CN41) from ONE

outdoor unit in the system and connect it to CN40.

*2 : If a system controller is used, set SW5-1 on all of the outdoor units to ON.

*3 : When a PAR-31MAA is connected to a group, no other MA remote controllers can be connected to the same group.

[Fig. 11.3.3] Combination of outdoor units and transmission booster unit

TB7

TB7

TB7

Ground

A

Group 1

B

Group 3

C

Group 5

D

Shielded wire

E

Sub remote controller

( ) Address

A

Group 1

B

Group 3

C

Group 5

D

Shielded wire

E

Sub remote controller

( ) Address

•

( ) Address

•

Daisy-chain terminals (TB3) on outdoor units in the same

refrigerant system together.

•

Leave the power jumper connector on CN41 as it is. When

connecting a system controller to the transmission line (TB7) for

centralized control, refer to [Fig. 11.3.1], [Fig. 11.3.2], or DATA

BOOK.