Thermistor (R) NG

1. The Thermistor (R) connector lead wire

1. Check all points of Thermistor (R) connector

isn't orderly.

lead wire, may be unlock and struck insert.

2. Thermistor (R) NG (break or short)

2. If the resistance of Thermistor (R) is NG,

should be replaced the Thermistor (R) and

re-check the resistance.

3. PCB plate (Ref Con assy) NG

3. If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

Thermistor (A.T.) NG

1. The Thermistor (A.T.) connector lead

1. Check all points of the thermistor (A.T.)

wire isn't orderly.

connector lead wire, may be unlock and

struck insert.

2. Thermistor (A.T.) NG (break or short)

2. If the resistance of Thermistor (A.T) is NG,

3. PCB plate (Ref Con assy) NG

should be replaced the Thermistor (R)

and re-check the resistance.

3. If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

1. DC motor is orderly connected.

1. Check all points of DC motor connector

lead wire, may be unlock and struck insert.

2. DC motor NG (Motor un-rotate and

2.

non-display)

re-check display.

3. PCB plate (Ref Con assy) NG

3. If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

1. DC fan motor is orderly connected.

1. Check all points of DC Fan motor connector

lead wire, may be unlock and struck insert.

2. DC fan motor NG (Motor un-rotated,

2. Replace DC fan motor (Outer motor assy)

and non-display.)

and check display.

3. PCB plate (Ref Con assy) NG

3. If the resistance is OK., should be replaced

PCB plate (Ref Con assy) and re-check the

resistance.

PCB plate (Ref Con assy) NG

1. PCB program (Ref Con assy) is NG

1. Replace a new PCB plate (Ref Con assy)

Refrigerant circuit is NG.

1. Pipe cracked (Welding joint)

1. Check and corrective to each problem.

2. Gas leak

3. Compressor NG

Remark :

1.) For the refrigerator is NG more than one case, will show as the first symptoms before, such as Thermistor (F) NG (1 blink in 0.3 seconds) and

Thermistor (R) NG (4 blinks in 0.3 seconds). LED will blink 1 blink in 0.3 seconds until Thermistor (F) was corrected. Then change to 4 blinks in 0.3 seconds

and LED won't blink when Thermistor (R) was corrected.

2.) Ice making stop LED blink during the operational test for ice maker.

3.) Compressor won't work if the fridge have problem and LED blink.

4.) Characteristic value may be changed due to the product improvement.

6 Blinks

Display function of LED

Light

No Light

Light

Function

Explanation

Detecting method and corrective NG points

4 Blinks

10 Blinks

11 Blinks

Fan motor (Outer motor assy) NG

Replace DC motor (Fan grille assy) and

No Light

Light

No Light

Fan motor (Fan grille assy) NG

Light

No Light

19 Blinks

Light

16 Blinks

No Light

No Light

Light

5 sec

1

2

3

1 Cycle

4

1

2

6

1 Cycle

1

2

1

2

10

1 Cycle

1

2

1

2

11

1 Cycle

1

2

1

2

16

1 Cycle

1

2

1

2

19

1 Cycle

1

2

0.3 sec

0.3 sec

0.3 sec

0.3 sec

0.3 sec

0.3 sec

17

Содержание MR-C375C-OB-A

Страница 2: ......

Страница 9: ... SKELETON WIRING DIAGRAM MR C375C A MR C375CL A MR C405C A MR C405CL A 3 WIRING DIAGRAM 7 ...

Страница 12: ...MR C375C A MR C375CL A MR C405C A MR C405CL A 5 NAMES OF PARTS 10 ...

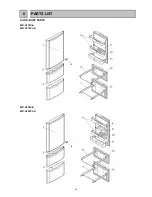

Страница 26: ...DOOR BODY PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 8 PARTS LIST 24 ...

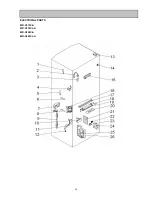

Страница 28: ...BODY PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 26 ...

Страница 30: ...ELECTRICIAL PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 28 ...

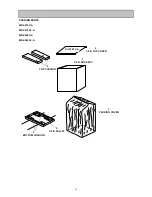

Страница 32: ...ACCESSORY AND UNIT PARTS MR C375C A MR C375CL A MR C405C A MR C405CL A 30 ...