8

Technical Information

3

26

*1 Refer to the following section [Local system].

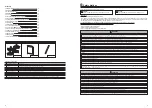

<Figure 3.2>

Note:

7RHQDEOHGUDLQLQJRIWKHF\OLQGHU

unit,

DQLVRODWLQJYDOYHVKRXOGEHSRVLWLRQHGRQERWKWKHLQOHWDQGRXWOHWSLSHZRUN

:LWKLQWKHEXLOGLQJEHVXUHWRLQVWDOODPDLQWDLQDEOHVWUDLQHU,WHPRQWKHLQOHWSLSHZRUNWRWKHF\OLQGHUXQLW6LPLODUO\RQWKHUHWXUQSLSHZRUNIURPVSDFHKHDWLQJ

FLUFXLWLWLVDOVRUHFRPPHQGHGWRLQVWDOODPDLQWDLQDEOHPDJQHWLFILOWHU,WHP

6XLWDEOHGUDLQSLSHZRUNVKRXOGEHDWWDFKHGWRDOOSUHVVXUHUHOLHIYDOYHVLQDFFRUGDQFHZLWK

national regulations.

:KHQXVLQJFRPSRQHQWVPDGHIURPGLIIHUHQWPHWDOVRUFRQQHFWLQJSLSHVPDGHRIGLIIHUHQWPHWDOVLQVXODWHWKHMRLQWVWRSUHYHQWDQ\

corrosive reaction

WDNLQJSODFH

ZKLFKPD\GDPDJHWKHSLSHZRUN

)LOOLQJORRSǯVIOH[LEOHKRVHPXVWEHUHPRYHGIROORZLQJWKHILOOLQJSURFHGXUH,WHPSURYLGHGZLWKXQLWDVORRVHDFFHVVRU\

,QVWDOOSULPDU\H[SDQVLRQYHVVHOWRWKHUHWXUQFLUFXLWRIVSDFHKHDWLQJDQG

ensure clear water

SDVVDJHEHWZHHQF\OLQGHUXQLWDQGSULPDU\H[SDQVLRQYHVVHO

Note:

0D[LPXPSULPDU\ZDWHUVXSSO\SUHVVXUHLVEDU03D

$WFRPPLVVLRQLQJVWDJHSOHDVHDGMXVWZDWHUSUHVVXUH

ZLWKLQSULPDU\FLUFXLWWREDUN3D

(+37490($!

Model name

EHPT20Q-VM2EA

Maximum

VHFRQGDU\SRWDEOHZDWHUVXSSO\SUHVVXUH

EDU03D

3ULPDU\H[SDQVLRQYHVVHOFKDUJHSUHVVXUH

EDUN3D

3ULPDU\SUHVVXUHUHOLHIYDOYHVVHWSUHVVXUH1RGHYLFHV

EDUN3D

Booster heater

VSHFLILFDWLRQ

N:9

3ULPDU\WKHUPDOVWRUHFDSDFLW\7DQNFDSDFLW\

/

NJ

Mass of the unit when full

0LQLPXPSULPDU\ZRUNLQJSUHVVXUH

EDUN3D

7DEOH!

1. Plate heat exchanger

2. Booster heater with thermostat

3. Drain cock (Primary circuit)

4. Drain cock (Secondary (Potable) circuit)

5. Pump valve

6. Water circulation pump 1

(For thermal store and space heating)

7. Water circulation pump A

(For hot water supply to plate heat exchanger)

8. 3-way valve

9. Manometer

10. Primary pressure relief valve

11. Automatic air vent

12. Manual air vent

13. Drain valve (Primary circuit)

14. Strainer valve

15. Flow sensor 1 (For space heating)

16. Flow sensor A (Secondary (Potable) circuit)

17. Flow sensor B (Primary circuit)

18. Primary thermal store tank

19. THW1 (Flow water temp. thermistor)

20. THW2 (Return water temp. thermistor)

21. THW3 (Flow water temp. thermistor 2 (to tank))

22. THW4 (DHW supply temp. thermistor)

23. THW5A (Stored water temp. thermistor (upper))

24. THW5B (Stored water temp. thermistor (lower))

25. Electrical isolation pipe

26. Manual thermostat

27. Non-return valve

28. Filling loop (Accessory item)

29. Primary expansion vessel (Accessory item)

30. Discharge pipe (Local supply)

31. Tundish (Accessory item)

32. I solating valve (Local supply)

33. Thermo mix valve (recommended) (Local supply)

34. Magnetic filter (recommended) (Local supply)

35. Strainer (Local supply)

,

nlet

0DLQVZDWHUVXSSO\

Outlet

DHW

18

1

2XWGRRU8QLW

48+=:9$

㻖䠖

Locally su

SS

lie

G

Water

SLS

e

13

19

27

*

1

2

21

22

23

3

2

11

7

12

27

3

8

6

29*

*

32*

32*

32*

33*

32*

32*

9

3D

12

3

17

16

Local system*1

HEX

&\OLQGHU8QLW

(+37490($

7RG

rain

7RG

rain

)OH[LEOHKRVH

7HPSRUDU\FRQQHFWLRQ

0DLQV:DWHUVXSSO\

28*

31*

31*

7RG

rain

Ű

Water circuit diagram

0D[LPXPSULPDU\ZRUNLQJSUHVVXUH

EDUN3D

9

Technical Information

3

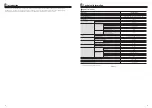

1-zone temperature control

1

Zone1

2

4

Zone1

Zone2

3

1

1

1-zone temperature control (2-zone valve ON/OFF control)

1. Heat emitters (e.g. radiator, fan coil unit) (local supply)

2. Zone1 2-way valve (local supply)

3. Zone2 2-way valve (local supply)

4. Auto-bypass valve (local supply)

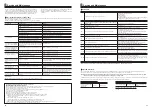

End user can monitor accumulated*1 ‘Consumed electrical energy’ and ‘Delivered energy’ in each operation mode*2 on the main controller.

*1 Monthly and Year to date

*2 - DHW operation

- Space heating

Refer to “5.7 Main controller” for how to check the energy, and “5.1 DIP switch functions” for the details on DIP-SW setting.

Either one of the following two method is used for monitoring.

Note: The method 1 should be used as a guide. If greater accuracy is required, then method 2 should be used.

Note: Consumed electric energy of pump A is automatically calculated by the system.

Booster heater

Pump1*1

Default

2kW

***(factory fitted pump)

EHPT20Q-VM2EA

2kW

***

<Table 3.5>

*1 "***" displayed in the energy monitor setting mode means the factory fitted pump is connected as pump 1 so that the input is automatically calculated.

When anti-freeze solution (propylene glycol) is used for primary water circuit, set the produced energy adjustment if necessary.

For further detail of above, refer to “5.7 Main controller”.

2. Actual measurement by external meter (locally supplied)

FTC has external input terminals for 2 ‘Electric energy meters’ and a ‘Heat meter’.

If two ‘Electric energy meters’ are connected, the 2 recorded values will be combined at the FTC and shown on the main controller.

(e.g. Meter 1 for main power line, Meter 2 for booster heater power line)

Refer to the [Signal inputs] section in “5.2 Connecting inputs/outputs” for more information on connectable electric energy meter and heat meter.

1. Calculation internally

Electricity consumption is calculated internally based on the energy consumption of outdoor unit, electric booster heater, pump1 and other auxiliaries.

Produced heat is calculated internally by multiplying delta T (Flow and Return temp.) and flow rate measured by the factory fitted sensors.

Set the electric booster heater capacity and water pump(s) input according to indoor unit model. (Refer to the menu tree in “5.7

Main controller”)

Ű

Local system

Ű

Energy monitoring