18

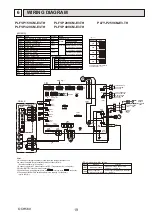

19

5

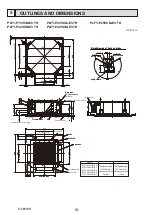

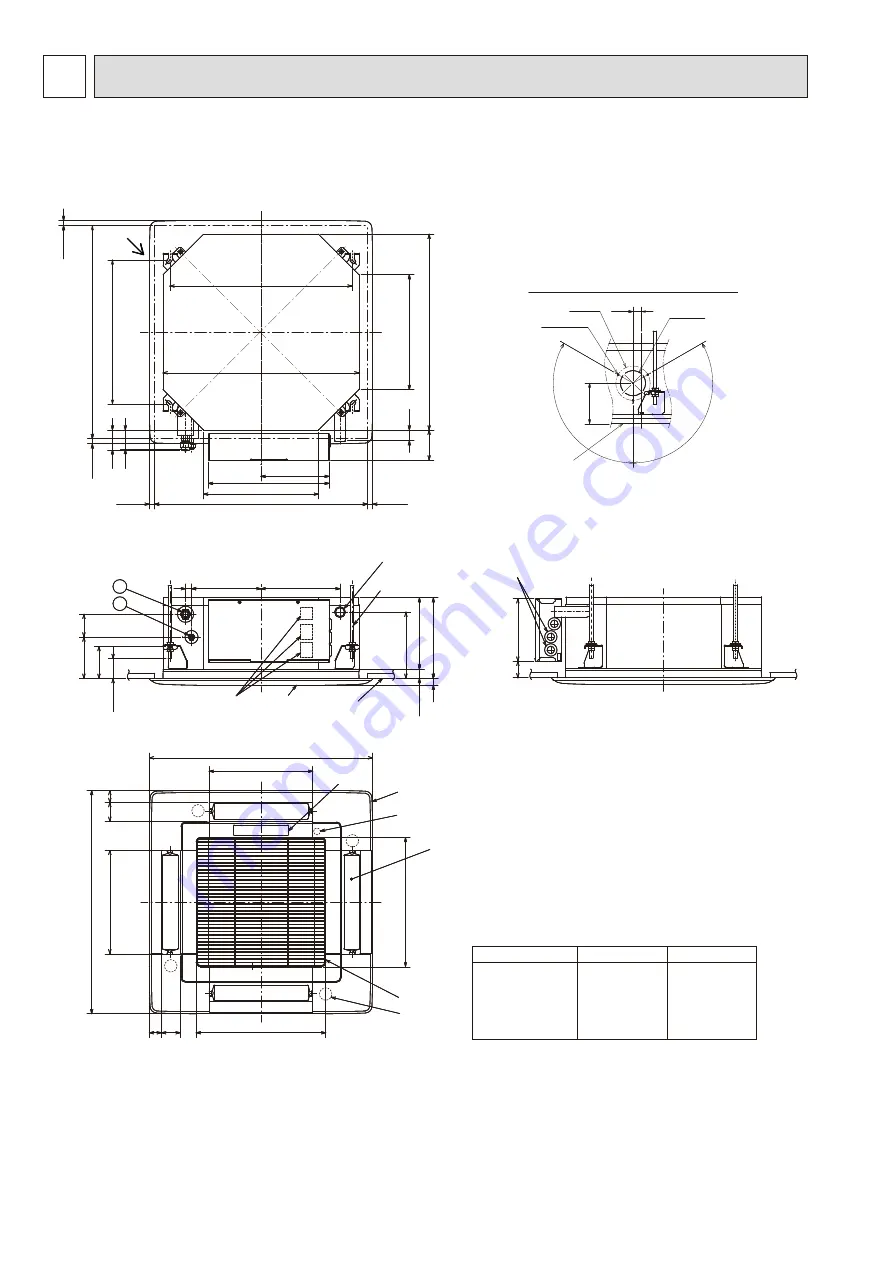

OUTLINES AND DIMENSIONS

Brand label

15~37

15~37

576~620

530

1

2

Grille

Fresh air intake

Drain pipe

VP-25 connection

Vane motor

Drain hole

V/M

V/M

V/M

V/M

Air intake grille

55

35

35 55

Auto vane

Grille

Air intake hole

Air intake hole

Air outlet hole

Air outlet hole

301

301

Detail drawing of fresh air intake

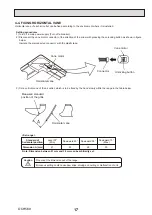

Ceiling surface

Cut out hole

[

73.4

Burring hole

3-

[

2.8

[

100

11

8

25

120

-

120

-

377

377

650

650

Suspension bolt M10 or W3/8

230

182

48

Terminal block

Ceiling surface

235

208

27

+5

0

193

20

93

38~58

66

121

17

202

87

31

Ceiling hole

15~37

576~620

420

570

335

199

352

335

Ceiling hole

Grille

Drain pipe

VP-25 connection

(O.D.

[

32)

Drain hole

55

35

35 55

Auto vane

Grille

Air intake hole

Air outlet hole

301

Detail drawing of fresh air intake

Ceiling surface

Cut out hole

Burring hole

11

8

25

377

377

650

182

48

Terminal block

235

208

27

+5

193

20

93

66

121

87

31

15~37

570

335

199

352

335

570

Grille

Drain pipe

Drain hole

55

35

35 55

Auto vane

Grille

Air intake hole

Air outlet hole

301

Detail drawing of fresh air intake

Ceiling surface

Cut out hole

Burring hole

11

8

25

377

650

Suspension bolt lower edge

182

48

Wiring entry

Terminal block

235

208

27

+5

193

20

93

66

121

56

57

87

31

Suspension bolt pitch

570

335

199

352

335

Suspension bolt pitch

Models

1

2

PLFY-P15VCM-E3

PLFY-P20VCM-E3

PLFY-P25VCM-E3

PLFY-P32VCM-E3

PLFY-P40VCM-E3

Refrigetant pipe

(6.35mm dia.)

flared connection

1/4 inch

Refrigetant pipe

(12.7mm dia.)

flared connection

1/2 inch

Unit: mm

PLFY-P15VCM-E3.TH

PLFY-P20VCM-E3.TH

PLFY-P25VCM-E3.TH

PLFY-P32VCM-E3.TH PLFY-P40VCM-E3.TH

OCH569