User Manual of DH-300/400 Full Automatic Soldering Robot

55

3.

Install the soldering bit in the soldering pencil rod, wrap new exposed

plating surface of the soldering bit with the tin wire (above φ0.8mm)

containing rosin, and turn on the power supply of the temperature control

system.

-

Proper routine maintenance will effectively prevent the

soldering bit from non-wetting.

Service life extension of soldering bit

1.

The soldering bit shall be wetted with the fresh soldering tin after use each

time, so as to prevent the soldering bit from being oxidized, thus

prolonging its service life.

2.

The soldering bit shall be used at lower temperature as far as possible

when it is capable of working. Low temperature can reduce the oxidization

of the soldering bit and helps to weld the components.

3.

Flux with less activated rosin shall be used because high-content activated

rosin will speed up the corrosion of the soldering bit plating.

4.

When the soldering bit is not used for welding, the power supply shall be

turned off as far as possible to prolong its service life.

5.

When the soldering bit is used to weld the workpieces, the greater pressure

shall not be exerted because greater pressure is not equal to rapid heat

transfer. To improve the heat transfer, soldering tin melting must be used

so that a soldering tin bridge for heat transfer is formed between the

soldering bit and the welding spot.

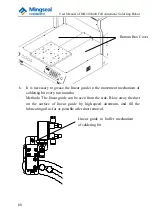

Instructions for replacement of heating core

The structure diagram of heating core is as shown in the following figure.