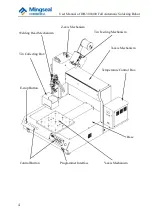

User Manual of DH-300/400 Full Automatic Soldering Robot

11

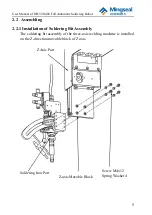

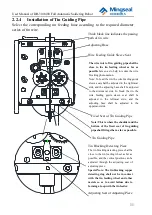

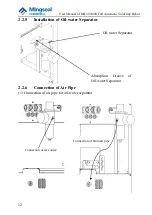

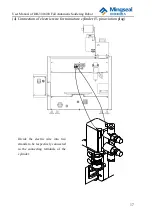

2.2.4

Installation of Tin Guiding Pipe

Select the corresponding tin feeding hose according to the required diameter

series of tin wire.

Adjusting Seat of Adjusting Piece

The wire inlet of tin guiding pipe shall be

close to the tin feeding wheel as far as

possible

here so as to help to reduce the wire

blocking phenomenon.

Note: To feed the tin, the wire feeding guide

sleeve seat shall be adjusted to the rightmost

side, and the adjusting base shall be adjusted

to the downmost side. To break the tin, the

wire feeding guide sleeve seat shall be

adjusted to the leftmost side, and the

adjusting base shall be adjusted to the

uppermost side.

Tin Blocking Detecting Piece

The tin blocking detecting piece shall be

close to the tin feeding wheel as far as

possible, and the vertical position can be

adjusted through the adjusting seat of

adjusting piece.

Special Note: The tin blocking copper

detecting ring shall not be in contact

with the tin feeding wheel and other

metals so as to avoid failure due to

forming a loop with the tin feeder.

Fixed Seat of Tin Guiding Pipe

Tin Guiding Pipe

Note: This is where the shoulder and the

bottom of the fixed seat of tin guiding

pipe shall fit together as far as possible.

Thick black line indicates the passing

path of tin wire

Adjusting Base

Wire Feeding Guide Sleeve Seat