Electric door lock

The washer-disinfector is equipped with

an electric door lock.

The door can only be opened when:

– the electrical power to the washer-

disinfector is turned on and

– is switched on with the

s

button,

and

– no wash or disinfection program is

running.

Opening the door

^

Press the

a

button. At the same

time, grip the handle and open the

door.

,

Do not touch the heating

elements when you open the door at

the end of a program. They remain

hot for several minutes after the

program has ended and can cause

burns.

How to close the door

^

Lift the door upward and push it until

it clicks shut.

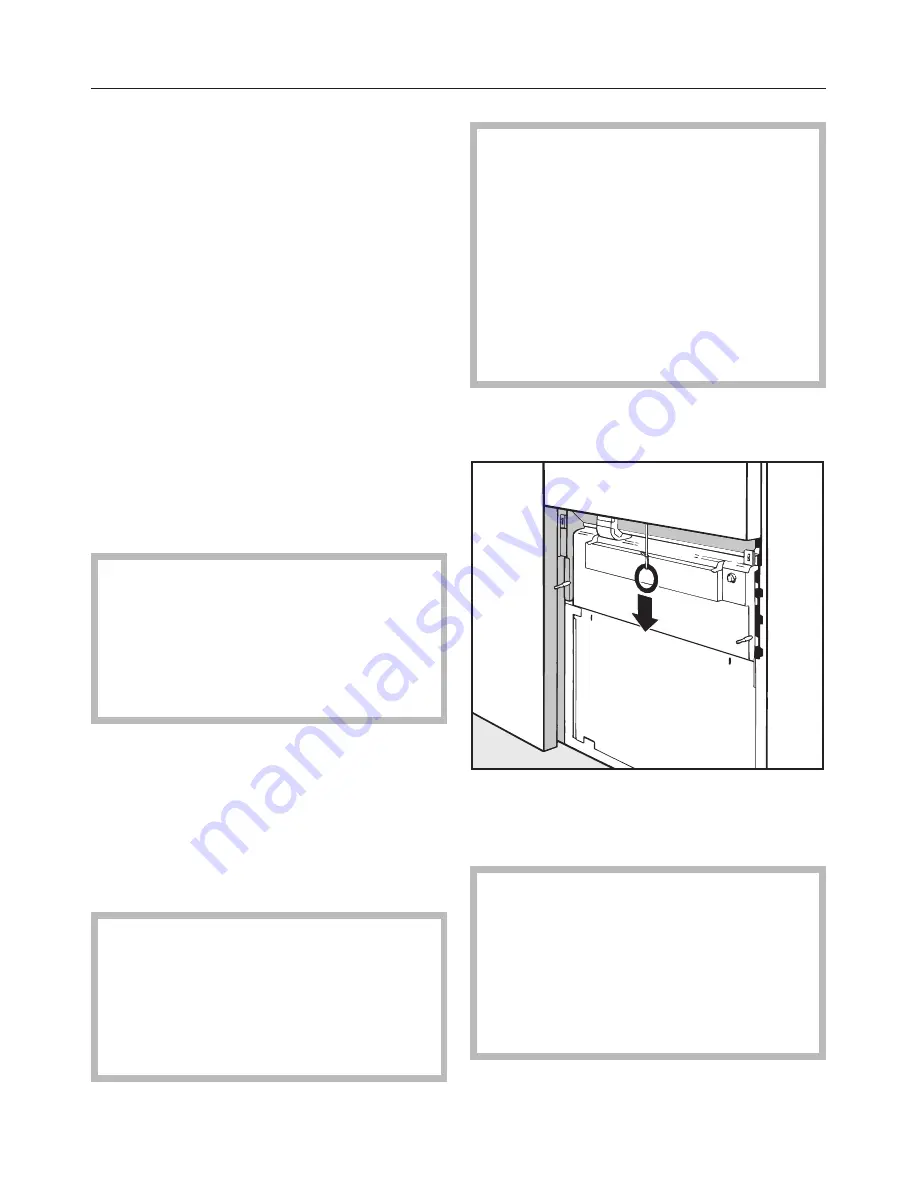

Opening the door with the

emergency release

,

The emergency release feature

should only be used when it is not

possible to open the door normally,

for example, during a power failure.

For all DESIN programs, please read

the "Important safety information".

,

If you bypass the electrical lock

to open the door, there is the danger

of scalding and heat or chemical

burns. If disinfectants have been

used, there is also the danger of

inhaling toxic vapour.

Do not touch the heating elements

when you open the door during a

program interruption. This can

cause burns.

^

Disconnect the washer-disinfector

from the electrical power grid.

^

Remove the service panel and pull

the ring downward for the emergency

release.

,

If there is a large volume of hot

water in the wash cabinet during an

emergency release, and the

washer-disinfector door is closed

too quickly, hot water can leak out.

There is the risk of scalding and

burning.

Opening and closing the door

25