Safety Precautions

2

1. Precautions

To prevent personal injury, or property or unit damage,

adhere to all precautionary measures and instructions

outlined in this manual. Before servicing a unit, refer to this

service manual and its relevant sections.

Failure to adhere to all precautionary measures listed in this

section may result in personal injury, damage to the unit or

to property, or in extreme cases, death.

WARNING

indicates a potentially hazardous

situation which if not avoided could result in serious

personal injury, or death.

CAUTION

indicates a potentially hazardous situation

which if not avoided could result in minor or

moderate personal injury, or unit damage.

1.1 In case of Accidents or Emergency

WARNING

•

•

If a gas leak is suspected, immediately turn off the

gas and ventilate the area if a gas leak is suspected

before turning the unit on.

•

•

If strange sounds or smoke is detected from the unit,

turn the breaker off and disconnect the power supply

cable.

•

•

If the unit comes into contact with liquid, contact an

authorized service center.

•

•

If liquid from the batteries makes contact with skin or

clothing, immediately rinse or wash the area well with

clean water.

•

•

Do not insert hands or other objects into the air inlet

or outlet while the unit is plugged in.

•

•

Do not operate the unit with wet hands.

•

•

Do not use a remote controller that has previously

been exposed to battery damage or battery leakage.

CAUTION

•

•

Clean and ventilate the unit at regular intervals when

operating it near a stove or near similar devices.

•

•

Do not use the unit during severe weather conditions.

If possible, remove the product from the window

before such occurrences.

1.2 Pre-Installation and Installation

WARNING

•

•

Use this unit only on a dedicated circuit.

•

•

Damage to the installation area could cause the unit

to fall, potentially resulting in personal injury, prop-

erty damage, or product failure.

•

•

Only qualified personnel should disassemble, install,

remove, or repair the unit.

•

•

Only a qualified electrician should perform electri-

cal work. For more information, contact your dealer,

seller, or an authorized service center.

CAUTION

•

•

While unpacking be careful of sharp edges around

the unit as well as the edges of the fins on the con-

denser and evaporator.

1.3 Operation and Maintenance

WARNING

•

•

Do not use defective or under-rated circuit breakers.

•

•

Ensure the unit is properly grounded and that a

dedicated circuit and breaker are installed.

•

•

Do not modify or extend the power cable. Ensure

the power cable is secure and not damaged during

operation.

•

•

Do not unplug the power supply plug during

operation.

•

•

Do not store or use flammable materials near the

unit.

•

•

Do not open the inlet grill of the unit during

operation.

•

•

Do not touch the electrostatic filter if the unit is

equipped with one.

•

•

Do not block the inlet or outlet of air flow to the unit.

•

•

Do not use harsh detergents, solvents, or similar items

to clean the unit. Use a soft cloth for cleaning.

•

•

Do not touch the metal parts of the unit when

removing the air filter as they are very sharp.

•

•

Do not step on or place anything on the unit or

outdoor units.

•

•

Do not drink water drained from the unit

•

•

Avoid direct skin contact with water drained from the

unit.

•

•

Use a firm stool or step ladder according to

manufacturer procedures when cleaning or

maintaining the unit.

CAUTION

•

•

Do not install or operate the unit for an extended

period of time in areas of high humidity or in an

environment directly exposing it to sea wind or salt

spray.

•

•

Do not install the unit on a defective or damaged

installation stand, or in an unsecure location.

•

•

Ensure the unit is installed at a level position

•

•

Do not install the unit where noise or air discharge

created by the outdoor unit will negatively impact the

environment or nearby residences.

•

•

Do not expose skin directly to the air discharged by

the unit for prolonged periods of time.

•

•

Ensure the unit operates in areas water or other

liquids.

•

•

Ensure the drain hose is installed correctly to ensure

proper water drainage.

•

•

When lifting or transporting the unit, it is

recommended that two or more people are used for

this task.

•

•

When the unit is not to be used for an extended time,

disconnect the power supply or turn off the breaker.

Содержание MUEU-18HRFNX-QRD0W

Страница 1: ...LIGHT COMMERCIAL INVERTER SERIES SM_LC GA _R410A_R32_3D INV_EU_NA_1811 SERVICE MANUAL...

Страница 2: ......

Страница 5: ......

Страница 6: ...Contents 1 Precautions 2 2 Information servicing For flammable materials 3 Safety Precautions...

Страница 12: ...Contents 1 Model Reference 2 2 External Appearance 3 Model Reference...

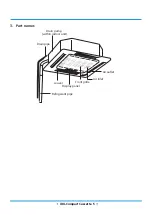

Страница 14: ...Model Reference 3 2 External Appearance 2 1 Indoor Unit Compact Four way Cassette A6 Duct Floor Ceiling...

Страница 15: ...Model Reference 4 2 2 Outdoor Unit Outdoor Unit...

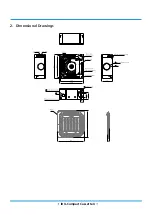

Страница 19: ...IDU Compact Cassette 4 2 Dimensional Drawings...

Страница 21: ...IDU Compact Cassette 6 4 Service Place...

Страница 24: ...IDU Compact Cassette 9 Heating airflow velocity distributions Heating temperature distributions...

Страница 26: ...IDU Compact Cassette 11 Heating airflow velocity distributions Heating temperature distributions...

Страница 44: ...Outdoor Unit 3 Panel Plate B30...

Страница 45: ...Outdoor Unit 4 Panel Plate BA30...

Страница 46: ...Outdoor Unit 5 Panel Plate CA30...

Страница 47: ...Outdoor Unit 6 Panel Plate D30...

Страница 48: ...Outdoor Unit 7 Panel Plate E30...

Страница 49: ...Outdoor Unit 8 Panel Plate 590...

Страница 50: ...Outdoor Unit 9 2 Service Place...

Страница 62: ...Outdoor unit printed circuit board diagram 17122000002718...