Installation Instructions

Rotary Encoders - Mounting

Page 6

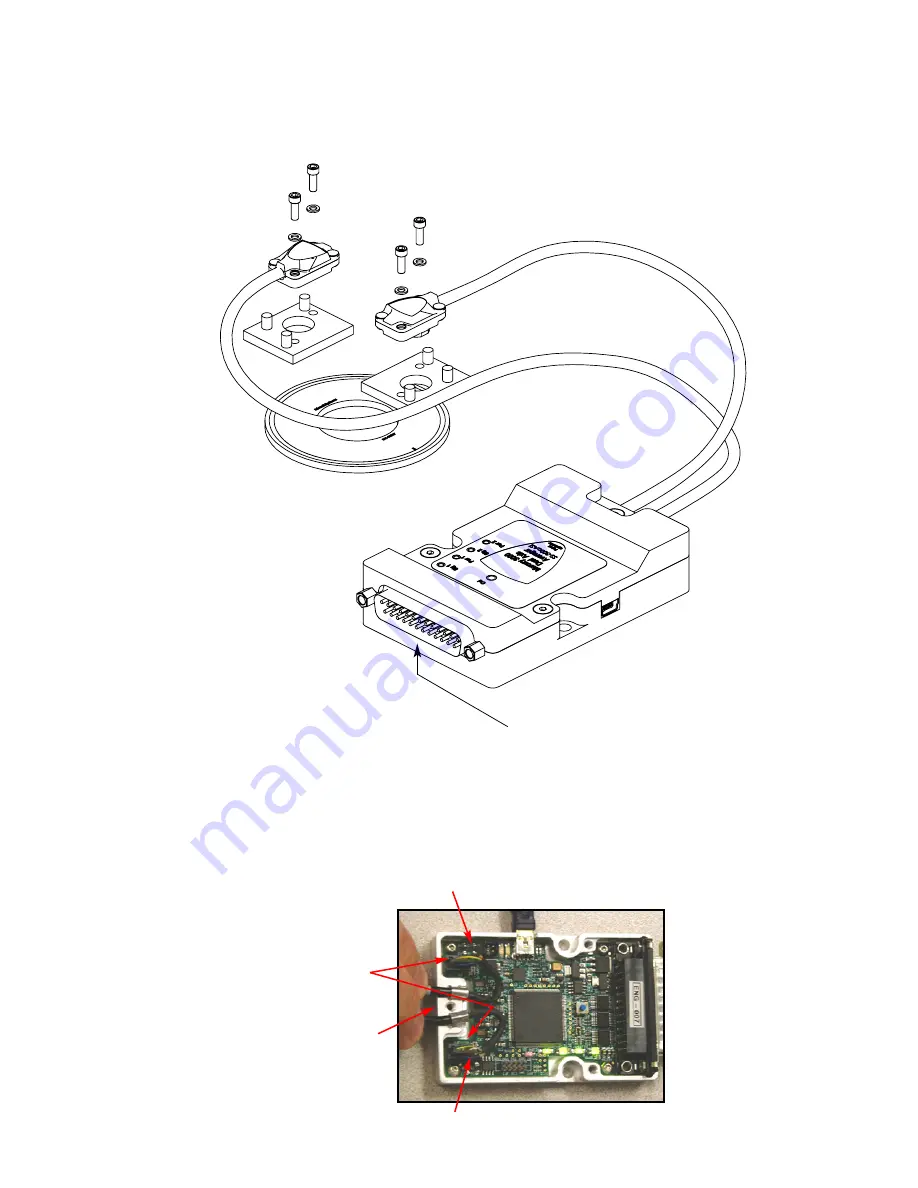

Attach your hub/scale

assembly to the rotary

device. Refer to the

interface drawing. The

reflective surface of the

scale must face the

sensors.

1

2

Install the sensors on your mounting surface referencing the

appropriate datum surface as shown on the interface drawing.

Use 2 washers per mounting screw.

Benching pins may be used to locate each sensor if the system

mechanical tolerances are adequate. See data sheet for alignment

tolerances, or keep mounting screws loose for sensor alignment if

benching pins are not used.

Be sure the source power is off before

connecting the SmartPrecision plug.

Connect the SmartPrecision electronics to the controller

using the pinout diagram described on the interface

drawing.

Insure proper system grounding. Refer to the procedure

on pg 9.

Power up the system. The Power and Signal indicators for

both sensors will illuminate.

4

3

CAUTION: observe precautions for handling elec-

trostatic sensitive devices.

Route the sensor cables through your equipment

to the Dual Axis SmartPrecision electronics module.

A) Remove the three cover screws and the top

half of the connector housing. Do not pull on

the 25-pin D-sub connector or the circuit

board under the insulation layer.

B) Attach each sensor's 5 X 2 connector to the

mating 5 X 2 connector on the circuit board.

C) Route the sensor cables through their channels

in the center of the connector body and place

the cable's hex sleeves in the matching recesses.

Attach the top half of the connector housing

to the bottom half using the three cover screws.

Sensor 2

Sensor 1