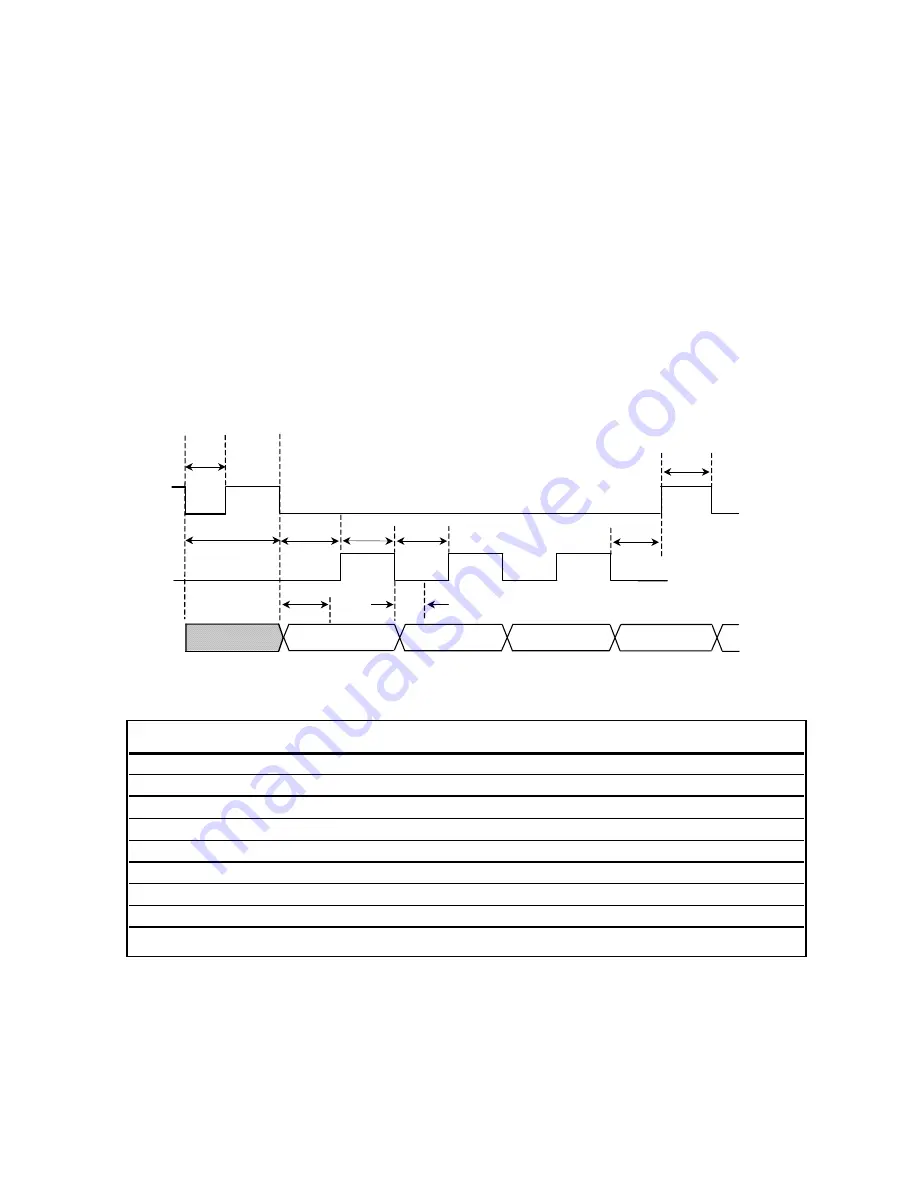

Operational Modes: Trigger Approach Timing Diagram

Symbol

Parameter

Minimum

Typical

Maximum

Units

tspiH

spiClock High Time

50

ns

tspiL

spiClock Low Time

50

ns

tTDR

n

_

spiEndable to DataReady

1420

1600

ns

tW

n

_

spiEnable Low for trigger

50

ns

tCSC

n_spiEnable to

spiClock

0

tCSD

n_spiEnable to DataValid

80

ns

tV

spiClock to Data Valid

80

ns

tCCS

spiClock to

n_spiEnable

0

ns

tCS

n_spiEnable High

50

ns

Trigger Approach Timing Diagram

The Trigger Approach can be used in applications where synchronization of the position data to an event is required. Often, this

mode is used when a fixed latency between a clock signal and the sampled position data is required. The customer can choose

this mode of operation by using the optional SmartPrecision Software. In this mode, triggering is controlled by the n_spiEnable

signal.

The falling edge of n_spiEnable signal starts the process by immediately resetting the internal calculators and acquiring the latest

A/D converter information. Old data in the calculation chain is discarded and the initiation of a new position calculation is started.

The new data is ready in 1420ns. The n_spiEnable signal for retrieving the data must be asserted within 210ns after the new data

is ready or the triggered acquisition will be over written by new data.

Shifting the data out of the interpolator's serial port is accomplished exactly as in the Standard Communication mode of operation.

In order to sample the next position, n_spiEnable must be brought high and then reasserted. See the Trigger Approach timing dia-

gram below.

tV

Clk1

Clk36

MSB

LSB

n_spiEnable

spiClock

spiDataOut

tTDR

tW

tspiH

tspiL

tCSC

tCSD

tCCS

tCS

Trigger Approach Timing Diagram

Page 23