Model 390

Page 11

2. Raise the jack off the ground. Remove the jack hub

pin and rotate the jack to horizontal storage position

and secure with the pin, Figure 2.

3. Connect the PTO drive shaft to the tractor PTO out-

put shaft and be sure it is locked to the tractor shaft.

4. If your spreader has an optional fine spread pan, tie

the rope control to a convenient place for operation

from the tractor seat.

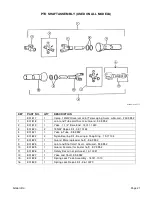

Hydraulic Apron Drive

1. Connect the two hydraulic hoses for the apron drive

to a set of remote ports on the tractor. These are the

two hoses coming from the hydraulic flow control valve.

NOTE:

One of the lines going to the flow control has a

check valve in it so that the apron cannot be operated

in the wrong direction. This line must be connected to

the tractor return port. If the hoses are reversed, the

apron will not operate and the hoses should be

switched, see Figure 3 or Figure 4.

2. A “control hose” is connected to the flow control lever

with the opposite end having a bracket to hook at a

convenient location on the tractor for operator conven-

ience. The flow control lever has a tension screw ad-

justment to regulate force to retain settings, see Figure

3 or Figure 4.

3. Connect the two hydraulic hoses for the end gate to

a second pair of tractor remote ports.

Hydraulic System

1. Most late model tractors use a Closed Center hy-

draulic system which only pumps oil as required. Some

other tractors may have an Open Center system which

pumps oil continuously, in which case provision must

be made to allow excess flow through the return hose

back to the tractor reservoir. If you are not sure of your

system, contact your tractor dealer.

2. The spreader is normally shipped with the apron

drive flow control valve plumbed for Open Centers as il-

lustrated on Figure 3. If you have a Closed Center,

close the ball valve as shown on Figure 4.

FIGURE 3. HYDR AULIC APRON DRIVE SET

FOR OPEN CENTER TR ACTOR HYDR AU-

LIC SYSTEM

FIGURE 4. HYDR AULIC APRON DRIVE SET

FOR CLOSED CENTER TRACTOR HY-

DR AULIC SYSTEM

FrontViewPhoto-390.JPG

FIGURE 2. JACK

Содержание 390 Tandem

Страница 18: ...Page 18 Model 390 REPAIR PARTS MAIN FRAME AND BOX PARTS...

Страница 22: ...Page 22 Model 390 FRONT AND SIDE DRIVE SHAFT AND RELATED PARTS...

Страница 24: ...Page 24 Model 390 APRON AND BEATER DRIVE CLUTCH AND RELATED PARTS RearHydDrive 300 tif...

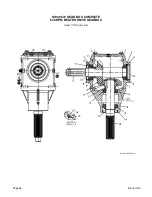

Страница 26: ...Page 26 Model 390 5490 0672 GEAR BOX COMPLETE 540 RPM BEATER DRIVE GEARBOX Used 11 13 and Later...

Страница 28: ...Page 28 Model 390 5490 0685 GEAR BOX COMPLETE 1000 RPM BEATER DRIVE GEARBOX Used 11 13 and Later...

Страница 30: ...Page 30 Model 390 E01300W GEAR BOX COMPLETE 540 RPM BEATER DRIVE GEARBOX Used 03 06 10 13 Last Serial No 18T13...

Страница 34: ...Page 34 Model 390 HYDRAULIC SYSTEM PARTS HydraulicParts 390 tif...

Страница 36: ...Page 36 Model 390 END GATE HYDRAULIC PIPING FOR OPTIONAL END GATE HydEndGatesParts 300 350 390 tif...

Страница 38: ...Page 38 Model 390 APRON DRIVE GEAR BOX HO382 GearboxParts 390 tif...

Страница 40: ...Page 40 Model 390 APRON DRIVE HYDRAULIC MOTOR HydMotorOpt 300 tif...

Страница 42: ...Page 42 Model 390 APRON AND RELATED PARTS ApronParts 390 tif...

Страница 44: ...Page 44 Model 390 BEATERS AND RELATED PARTS...

Страница 50: ...Page 50 Model 390 This Page Intentionally Blank...

Страница 51: ...Model 390 Page 51 This Page Intentionally Blank...