Model 390

Page 13

OPERATION

CAUTION

DO NOT USE JACK EXCEPT WHEN SPREADER IS

EMPTY. JACK WILL NOT SUPPORT ADDED WEIGHT

FROM LOAD. UNBALANCED WEIGHT MAY RESULT

IN UNEXPECTED “TIP UP” OF THE SPREADER.

DANGER

NEVER ENTER THE SPREADER BOX FOR ANY

REASON WITHOUT FIRST DISCONNECTING PTO

SHAFT FROM TRACTOR. DO NOT ALLOW OTHERS

IN THE BOX. ROTATING BEATER CAN DISMEMBER

OR KILL.

LOADING

1. If you have an optional hydraulic end gate or fine

spread pan, be sure they are closed, Figure 6 and

FIGURE 8. When the spreader is parked for loading,

shift the tractor to neutral or park and set the brakes.

The moisture content of the manure will determine how

full the spreader can be loaded so that no manure spills

out.

2. You will probably be able to load solid manure at

least level with the top of the box while semi liquid and

liquid slurries will have to be less than full in the

spreader box.

NOTE:

It is unlawful to allow slurry to splash or leak on-

to public roads.

UNLOADING

WARNING

MAKE CERTAIN EVERYONE IS CLEAR OF EQUIP-

MENT BEFORE APPLYING POWER. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL INJU-

RY OR DEATH.

DANGER

KEEP AWAY AND KEEP OTHERS CLEAR OF RO-

TATING BEATERS AT REAR OF SPREADER. SERI-

OUS INJURY OR AMPUTATION COULD RESULT.

1. The rear beaters have been designed and tested to

provide the best spread pattern for most liquids and

semi solid manure. However, the pattern will vary for

each specific condition. The factors that contribute most

to differing patterns will be moisture content and the

amount and length of bedding material. For most typical

conditions, the spread pattern should be uniform and

about the width of the spreader. Plan your spreading

patterns so you do not have to travel over previously

spread manure which will be slippery, resulting in poor

traction. Traction on wet grass is also poor. When the

resulting pattern may require that you overlap during

spreading, use precautions on slopes and hills where

you will experience a loss of traction by traveling over

ground with previously spread manure.

2. Perform the following operations when you are

ready to begin spreading application on the field, de-

pending on the options your spreader is equipped with.

Hydraulic Apron Drive

1. Turn hydraulic power on with tractor hydraulic con-

trol and then start the apron chain. This is done from

the tractor by turning the flow control clockwise, locat-

ed at the front of the spreader. This control is operated

from the tractor by twisting the “hose control”, Figure 7.

“OFF” is when this control is rotated fully CCW. For

solid manure, start the apron at a slow rate of speed.

Start application onto the field. Increase speed of

apron chain for a heavier application.

2. There is a tension screw that can be adjusted to

regulate the force required to operate the flow control

valve, see Figure 3 or Figure 4.

3. Further control of the application rate is possible by

changing ground speed (transmission gear selection).

For optimum trouble free performance it is recom-

mended to operate at or near engine PTO speed.

4. When the spreader is unloaded, or when the ma-

nure level is below the beater, it is possible to stop the

beater by disengaging the PTO on the tractor. This al-

lows the spreader apron to continue without the beat-

ers running for clean out.

5. When the spreader is empty, stop the PTO and

then stop the apron chain so there is no chain slat un-

der the hydraulic end gate, FIGURE 8. Then close the

end gate.

Optional Fine Spread Pan

If the pan is left closed, the spread pattern will be thin-

ner, more even, and narrower than normal. If normal

spreading is desired, trip the pan by pulling the rope

control immediately after beginning the spread applica-

tion, see Figure 6.

Содержание 390 Tandem

Страница 18: ...Page 18 Model 390 REPAIR PARTS MAIN FRAME AND BOX PARTS...

Страница 22: ...Page 22 Model 390 FRONT AND SIDE DRIVE SHAFT AND RELATED PARTS...

Страница 24: ...Page 24 Model 390 APRON AND BEATER DRIVE CLUTCH AND RELATED PARTS RearHydDrive 300 tif...

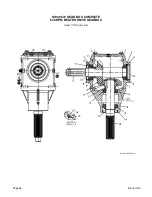

Страница 26: ...Page 26 Model 390 5490 0672 GEAR BOX COMPLETE 540 RPM BEATER DRIVE GEARBOX Used 11 13 and Later...

Страница 28: ...Page 28 Model 390 5490 0685 GEAR BOX COMPLETE 1000 RPM BEATER DRIVE GEARBOX Used 11 13 and Later...

Страница 30: ...Page 30 Model 390 E01300W GEAR BOX COMPLETE 540 RPM BEATER DRIVE GEARBOX Used 03 06 10 13 Last Serial No 18T13...

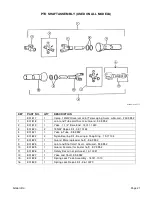

Страница 34: ...Page 34 Model 390 HYDRAULIC SYSTEM PARTS HydraulicParts 390 tif...

Страница 36: ...Page 36 Model 390 END GATE HYDRAULIC PIPING FOR OPTIONAL END GATE HydEndGatesParts 300 350 390 tif...

Страница 38: ...Page 38 Model 390 APRON DRIVE GEAR BOX HO382 GearboxParts 390 tif...

Страница 40: ...Page 40 Model 390 APRON DRIVE HYDRAULIC MOTOR HydMotorOpt 300 tif...

Страница 42: ...Page 42 Model 390 APRON AND RELATED PARTS ApronParts 390 tif...

Страница 44: ...Page 44 Model 390 BEATERS AND RELATED PARTS...

Страница 50: ...Page 50 Model 390 This Page Intentionally Blank...

Страница 51: ...Model 390 Page 51 This Page Intentionally Blank...