1.

GENERAL

1.1

Scope of the Manual

This instruction manual contains important information

regarding the installation, operation and maintenance of the

Jamesbury® Reactor Discharge Valves 8” - 12” 530S & 5300,

6” - 10” 6300 Digester Blow Valves, 8” -12” 530SB & 5300SB

and 6” - 10” 6300B Flanged Ball Valves. Please read these

instructions carefully and save them for future reference.

WARNING

FOR YOUR SAFETY, IT IS IMPORTANT THAT THE FOLLOWING

PRECAUTIONS BE TAKEN PRIOR TO REMOVAL OF THE VALVE FROM

THE LINE OR BEFORE ANY DISASSEMBLY:

1.

WEAR ANY PROTECTIVE CLOTHING OR EQUIPMENT NORMALLY

REQUIRED WHEN WORKING WITH THE FLUID INVOLVED.

2.

DEPRESSURIZE THE LINE AND CYCLE THE VALVE AS FOLLOWS:

A. PLACE THE VALVE IN THE OPEN POSITION AND DRAIN THE

LINE.

B. CYCLE THE VALVE TO RELIEVE RESIDUAL PRESSURE IN THE

BODY CAVITY BEFORE REMOVAL FROM THE LINE.

C. AFTER REMOVAL AND BEFORE ANY DISASSEMBLY, CYCLE

THE VALVE AGAIN SEVERAL TIMES.

3.

SEAT AND BODY RATINGS - THE PRACTICAL AND SAFE USE OF

THIS PRODUCT IS DETERMINED BY BOTH THE SEAT AND BODY

RATINGS. READ THE NAME TAG AND CHECK BOTH RATINGS.

THIS PRODUCT IS AVAILABLE WITH A VARIETY OF SEAT

MATERIALS. SOME OF THE SEAT MATERIALS HAVE PRESSURE

RATINGS THAT ARE LESS THAN THE BODY RATINGS. ALL OF

THE BODY AND SEAT RATINGS ARE DEPENDENT ON VALVE

TYPE AND SIZE, SEAT MATERIAL AND TEMPERATURE DO NOT

EXCEED THESE RATINGS.

2. INSTALLATION

If there is weepage past the stem seals upon installation,

it means the valve may have been subject to wide

temperature variations in shipment. Leak tight performance

will be restored by a simple stem nut adjustment described

in the MAINTENANCE section.

These valves may be installed for flow in either

direction. To ensure that good installation is achieved,

standard piping practices should be followed. FOLLOW

THE RECOMMENDED PRACTICES OF THE GASKET

MANUFACTURER WHEN TIGHTENING FLANGE BOLTS.

3. MAINTENANCE

3.1

General

Although Metso’s

Jamesbury

valves are designed to work

under severe conditions, proper preventative maintenance

can significantly help to prevent unplanned downtime and

in real terms reduce the total cost of ownership. Metso

recommends inspecting valves at least every five (5) years.

The inspection and maintenance frequency depends on

the actual application and process condition.

Routine maintenance consists of tightening the stem nut

(I5) periodically to compensate for stem seal wear.

Overhaul maintenance consists of replacing seats and

seals. A standard Repair kit consisting of these parts may be

obtained through your Metso distributor.

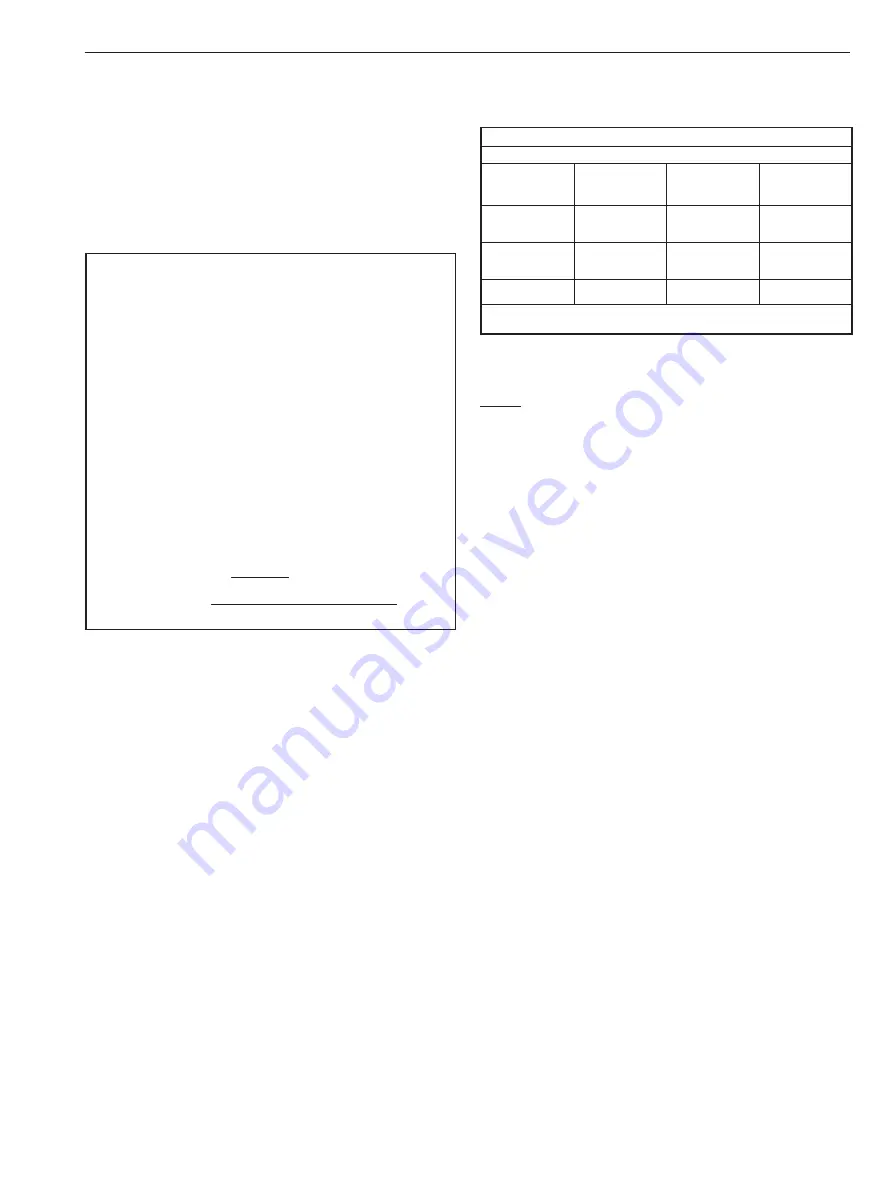

TABLE 1

REPAIR KITS

VALVE

SIZE

6” 6300

8” 530S

8” 5300

8” 6300

10” 530S

10” 5300

10” 6300

12” 530S

12” 5300

FILLED

TFE

SEATS

RKY34QA

RKY35QA

RKY36QA

VALVE

SIZE

6” 6300B

8” 530SB

8” 5300B

8” 6300B

10” 530SB

10” 5300B

10” 6300B

12” 530SB

12” 5300B

3I6SS/FILLED

TFE SEATS

RKN67WN*

RKN69WN*

RKN72WN*

* These kits contain two types of bearing spacers (28).

See Figure 5 for the proper bearing spacer to be used.

3.2

Disassembly

NOTE: If complete disassembly becomes necessary,

replacement of all seats and seals is recommended. Refer to

the Repair Kit chart on page one.

1. Follow the steps in the WARNING section before

performing any work on the valve.

2. Open and close the valve and leave in the closed position.

3. Place the valve in a vertical position with the body

cap (2) facing upward and the ball closed. (parts are

numbered per Figure 5.)

4. Remove the stem nut (15) stem nut lock (9) (if fitted),

compression ring (21) and four hex head cap screws (29).

5. Remove the stem (4) and stem retainer (30) as a

subassembly. It may be necessary to loosen with a

block of wood and hammer.

6. Press down on top of the stem (4) to remove it from the

stem retainer (30).

7. Remove the secondary stem seal (7) and the stem

bearing (8) from the stem. Pry out and discard the upper

stem seal set (32) from the stem retainer (30), BEING

CAREFUL NOT TO SCRATCH ANY SEALING SURFACES.

8. Remove and discard the stem retainer seal (25) from

the body.

9. Remove the body fasteners (11) for 6300 and 5300

valves, or (34) for 530S valves.

10. Lift the body cap (2) off of the body (1), BEING

CAREFUL NOT TO NICK OR SCRATCH THE BALL.

11. Remove the ball (3) and trunnion plates (26) as a

subassembly. (The subassembly consists of the

ball with, a trunnion plate on both ends with their

appropriate bearings and spacers.)

12. Pull each trunnion plate away from the ball and remove

the bearing spacer (28) and trunnion bearing (27).

IMO 11/17

IMO-302 EN

3

Содержание 5300

Страница 11: ...IMO 11 17 IMO 302 EN 11 ...