19

®

ARC160 - NLFREN - v1.0 - 03032014

EN

5 Maintenance

• Use clean and dry, low-pressure air to blow dust and dirt from the outer parts of the unit and torch. Clear the dirt,

dregs and grime from the head of welding torch.

• When the wire on the feed reel is used up, you will need to replace it. You can purchase replacement wire from your

supplier.

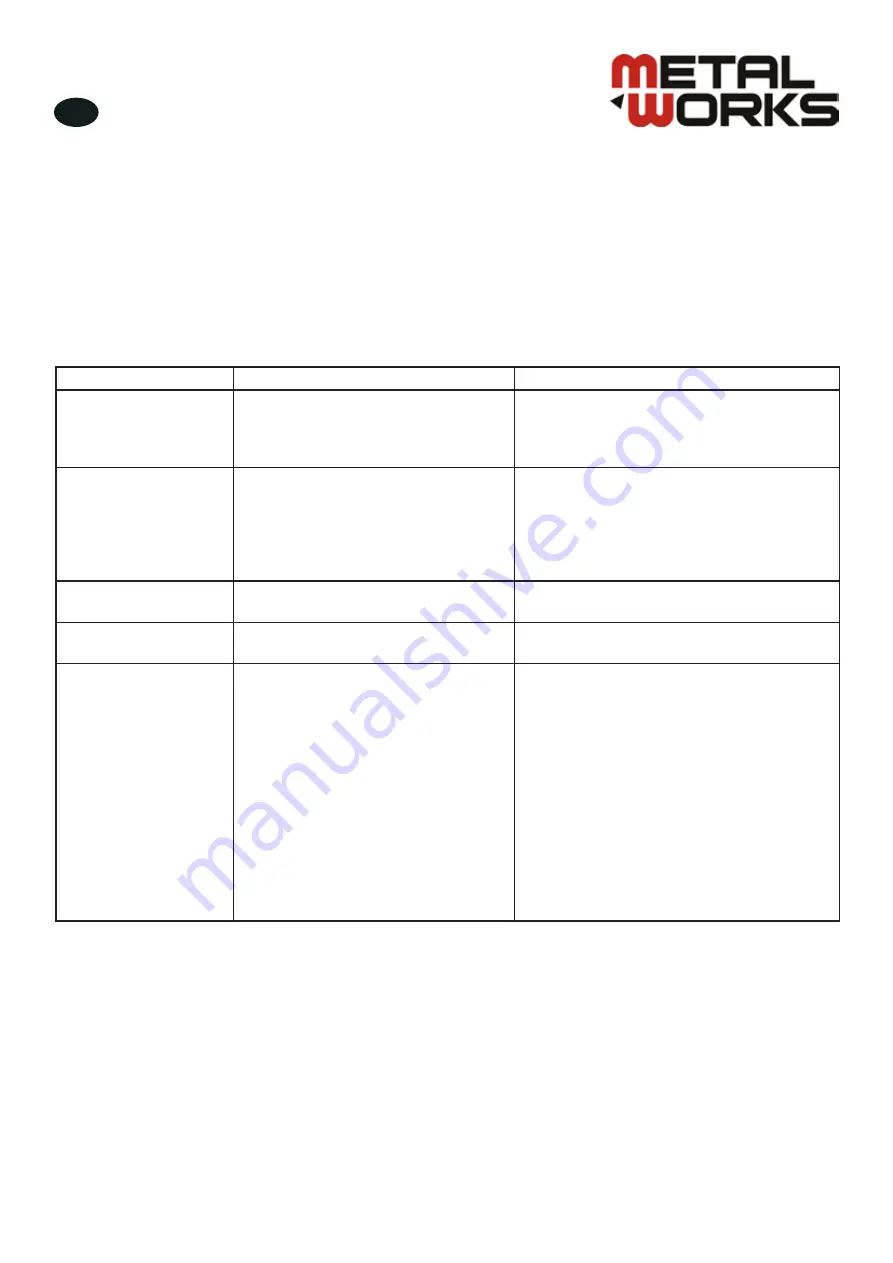

6 Trouble shooting

Trouble

Cause

Solution

Without output

- Without voltage in input terminal.

- Improper fuse or breaker.

- Overload protective setting.

- Check the fuse or breaker.

- Replace fuse or breaker.

- After cooling then try to continue.

Current is too poor

- Input voltage is too poor.

- Bad connection.

- One or more commute element have

been damaged.

- Check that if input voltage is the same with

rated voltage.

- Check grounding cable and make sure have

well connection.

- Replace.

After turning on the

welder does not work

- Control wire broken off.

- Circuit plate damaged.

- Check and replace.

- Replace circuit plate.

Arc does not transfer

- Loose of missing connections in the

cables.

- Check all cables and plugs.

Important

: unplug at the mains first.

Difficulty in arc starting

- Torch assembled incorrectly.

- Low voltage problems.

- Check torch assembly.

- Check electrodes and nozzles for blockage or

damage.

- Keep the voltage as stable as possible.

If the voltage is lower than rated input voltage:

1. The welding current is too low.

2. The arc may break or be unstable.

If the voltage is higher than rated input voltage:

1. The welding current is too high.

2. It will make noise.

4. It shortens the service life of welder.

copyrighted

document

- all

rights

reserved

by

FBC