The correct adjustment of this hydrant can be checked by raising the lever. Water

should not run through the hydrant until the lever passes the half way point or horizontal position. When water is flowing

through the hydrant it should shut off when the lever comes down to the horizontal point. The last half travel of the lever in

closing the hydrant opens the drain hole. Also in turning the hydrant on, the first half travel of the lever puts the cup seals in

position to positively close the drain before the water is turned on. This advanced patented feature is found only in the Merrill

Manufacturing™

Any Flow®

Hydrant.

Adjusting the plunger in the lower valve body

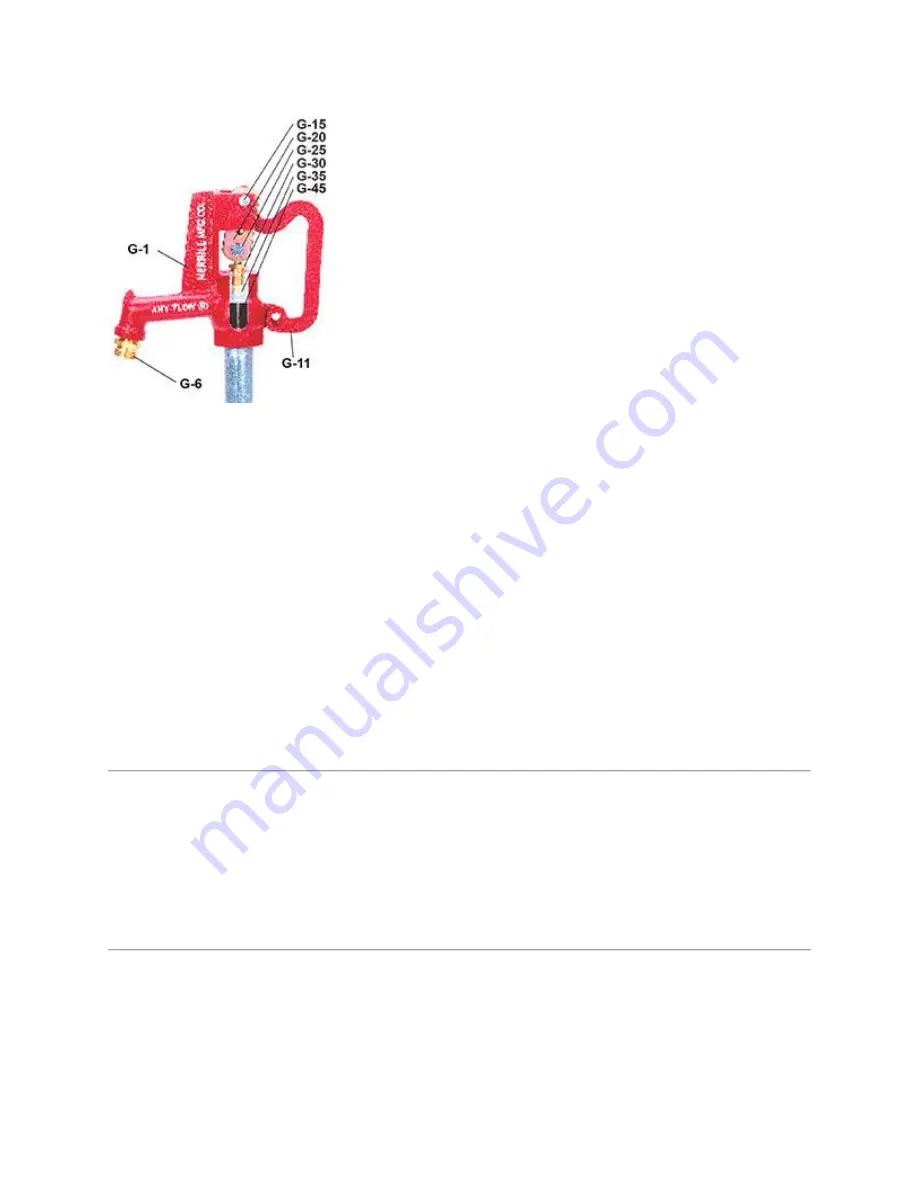

• To lower the plunger assembly into the valve body, take the G-15 bolt out of the head casting and remove the handle and G-20

draw straps (Note: draw straps are bent inward which applies pressure on the handle when opening the hydrant). With two

wrenches loosen the (2) 9/16" nuts on each side of the G-25 pivot connector. To lower the plunger, turn the top nut upward, only

one thread, then tighten the lower nut upward toward the G-25 pivot connector (or raise the G-25), then tighten the top nut.

• To determine if the water is not draining out of the stand pipe, turn the hydrant on and let the water flow. Then push down the

handle to close the hydrant with a cup of water covering the nozzle. If the water in the cup siphons back through the hydrant, the

plunger is in the correct position. If the water does not siphon out of the cup, then adjust the plunger in the same way as stated

above. Then check to see if the water siphons out of the cup after adjustment.

Any Flow®

Yard Hydrant Maintenance Instructions

In maintenance, nothing is needed - but, a few drops of oil occasionally on the cam of the lever will prolong its life.

If the hydrant should ever need a new seat washer - it uses a beveled bibb washer.

To replace any valve or plunger parts,

NO NEED TO DIG UP HYDRANT

, first turn off water pressure, then simply mark the

threads on the pipe by putting a piece of electrical tape around the pipe just below the hydrant head and unscrew entire head

casting from stand pipe and pull up stem and valve parts. Then thread head casting back to same mark on pipe after parts are

replaced.