EN

G

L

ISH

EN

G

L

ISH

6 EN

EN 7

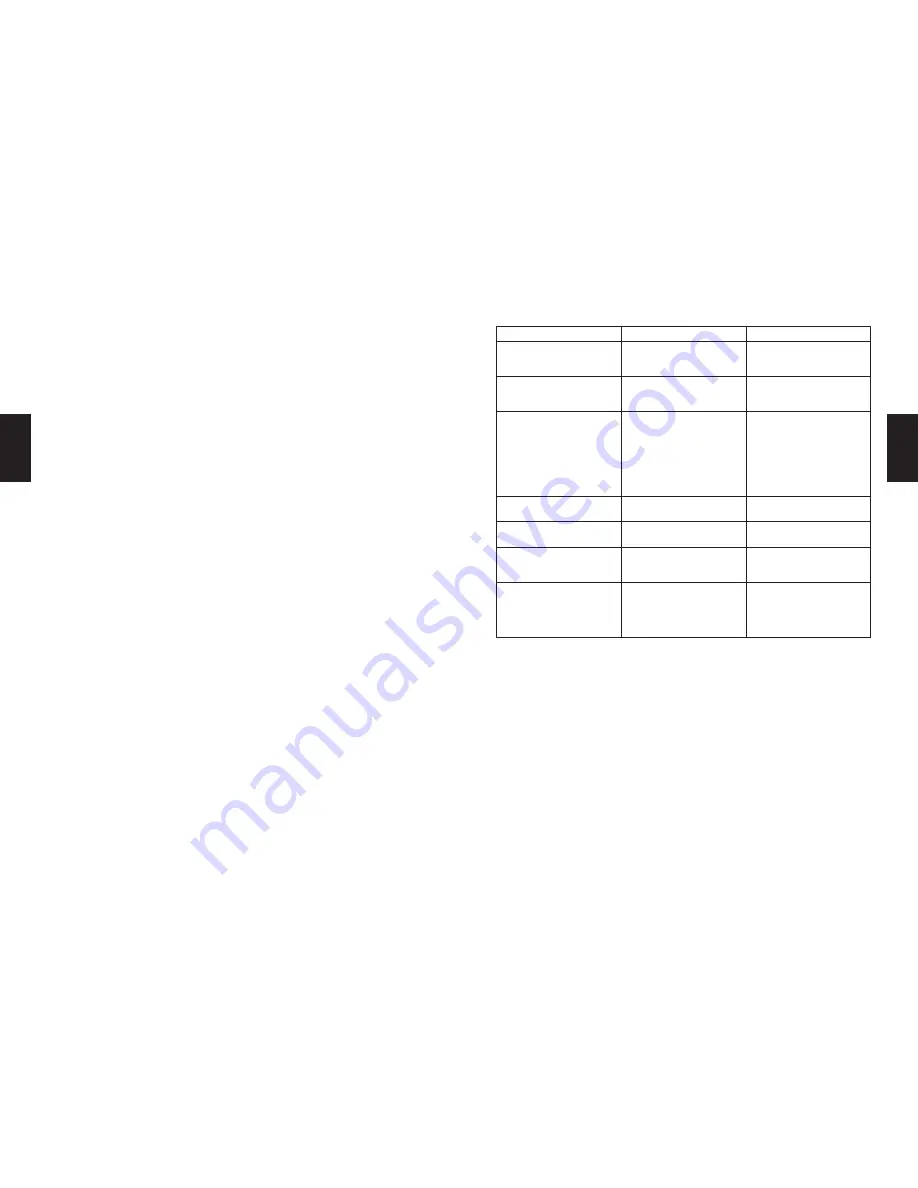

5.1 Troubleshooting

Problem

Possible cause

Correction

The treated surface is too

narrow.

The sanding drum is positioned

incorrectly.

Position the drum correctly

by adjusting the machine‘s

wheels.

The abrasive is used on only

one side.

The sanding drum is

positioned incorrectly.

Position the drum correctly

by adjusting the machine‘s

wheels.

The machine produces

excessive amounts of dust.

1. The fan unit or the suction

tube is clogged.

2. The pressure on the sanding

belt is insufficient.

3. The dust bag is too full.

4. The dust bag is blocking the

outlet of the dust capture

system.

1. Clean the dust capture

system.

2. Increase the pressure on the

sanding belt.

3. Empty the dust bag.

4. Position the attached dust

bag correctly.

The motor axle turns but does

reach the desired speed.

The power source is faulty or

supplying no voltage.

Check the power supply

voltage.

The motor whines, does not

speed up and overheats.

Start the motor on no-load.

The machine vibrates

excessively.

The sanding drum or sanding

belt is not attached correctly.

Check that the drum and belt

are correctly adjusted.

The treated surface has burn

marks on it.

1. The abrasive is worn out.

2. The pressure on the drum is

too great.

3. The sanding belt is too

narrow.

1. Replace the abrasive.

2. Reduce the sanding

pressure.

3. Use a wider sanding belt.

5. Maintenance

At the end of every day of working with the belt

sander, the following maintenance measures

should be taken:

• Clean the machine of dirt and sanding dust

after every use to prolong its operating lifetime.

This will also prevent the machine from being a

fire hazard after you are finished with your work.

• Check the V-belt tension and loosen any parts

of the machine that are under tension.

• Inspect the power cables for damage and

check the electrical contacts.

• Remove the dust bag and empty it as recom

-

mended.

• Check that the screws are tight, and give the

sanding belt some slack or remove it from the

machine entirely.

In addition to the recommended daily mainte-

nance measures, the following tasks should be

completed after approx. every 400 hours of use

(PM 1):

• Clean the dust suction and capture system.

Check that the fuses are intact and the cable con-

nections to the control unit are firm and undam

-

aged. If you discover any defects in the electrical

systems of the machine, have them repaired by a

trained professional.

• Tighten all screw joints and lubricate all moving

parts of the belt sanding machine. Do not forget

to lubricate the bearings as well.

Further periodic maintenance tasks should be

completed after approx. every 1,400 hours of

use (PM 2): In addition to completing the steps

of PM 1, clean the ventilation system and the

drums.

4. Storage

When storing the machine for extended periods

of time or transporting it over long distances,

protect any uncovered surfaces from corrosion

using a rust-protective oil compound. Loosen

the V-belt when storing the machine for an

extended period of time. The machine must not

be exposed to wet or damp storage conditions.

Therefore, always store it in dry rooms. Also,

always make sure to store the machine out of the

reach of children.

Содержание BSM 750 E

Страница 14: ......