07

Equipment

Lubrica�on

• Keep machine rota�ng parts lubricated, such as: pinion, rack gear,

bushings, and bearings;

• Lubricate the equipment at the beginning of opera�on, applying

grease to all lubrica�on points;

• Lubrica�on of the pinion/rack gear assembly is not recommended due

to the fact that aggregates such as sand, cement and gravel dust, among

others, can adhere to the lubrica�ng agent, causing the mixture to

become extremely abrasive, thus resul�ng in premature wear.

• When lubrica�ng the pimion sha� bearing, the concrete mixer drum

must be in a posi�on where the steel yoke arm is perpendicular (90°) in

rela�on to the machine column and the drum mouth must be turned to

the same side where the grease fi�ng is. If not, the bearings will not be

lubricated;

Esso: Beacon 2

Mobil: Mobilux 3

Shell: Shell Avania R2

Texaco: Mul�Flax EPO

Castrol: Graxa LM2

Atlan�c: Litholine 2

Recommended Greases

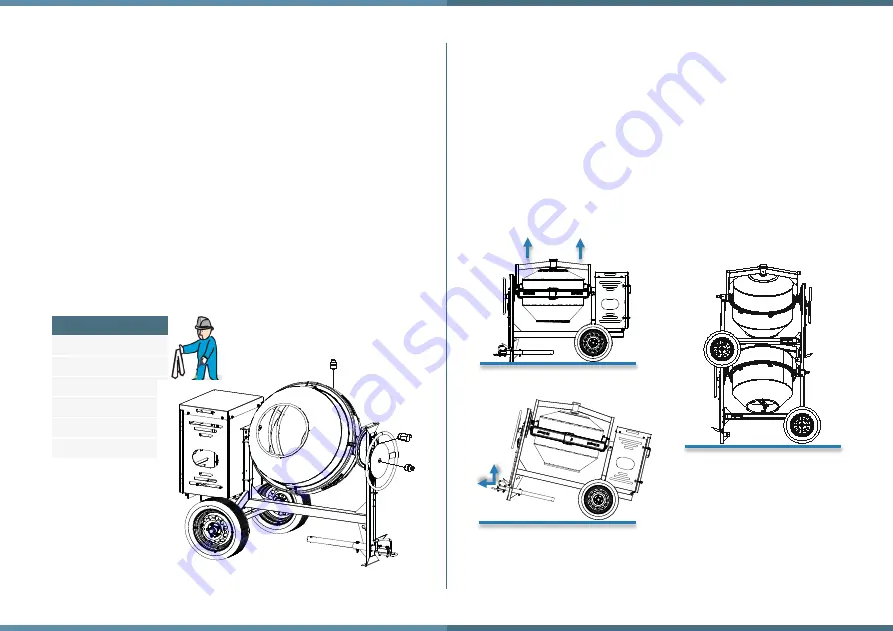

Transport, Li�ing and

Storage

• It has yoke just to raise a few cen�meters of soil and carry through the

movement of the wheels;

• They should be used by �l�ng, with the barrel facing down, while

maintaining the flatness of the mixer;

• Feature based on the columns for storing one on the other, fixa�on is

by screws, use only one level of stacking;

Transport

Li�ing

Storage