DESCRIPTION OF TESTS

The description of tests contained within this user guide are instructions for the use of the DET family of instruments by

competent persons.

Suitable applications

Where there is doubt about a particular application, reference should be made to the advice and guidance contained in the

publication, “Getting Down to Earth” which is available from Megger, part number 21500-072.

The DET range of instruments can be used in agricultural locations (as per IEC 61557-5). In these circumstances, the output

voltage should be switched to 25 V in order to comply with the standard.

The DET range of instruments makes resistance measurements using a switched DC signal at a frequency of 128 Hz. The

DET4TC2 and DET4TCR2 provide the user with the option to select 94 Hz,

105 Hz, 111 Hz or 128 Hz as the test frequency.

Note about measurements: when connecting the instrument to electrodes, ensure that any leads and cables are fully

unwound and laid out without loops.

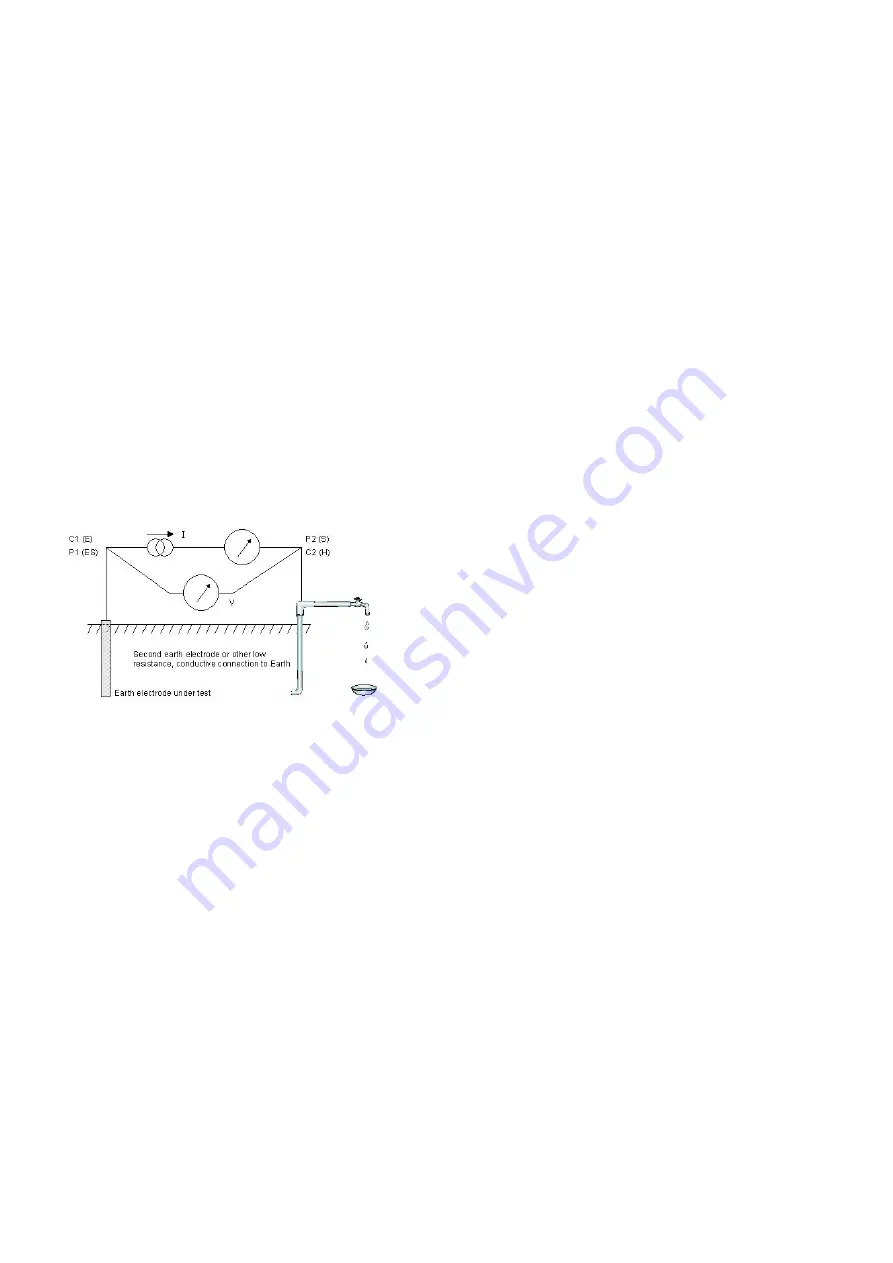

Principle of operation (two-terminal resistance measurement)

This technique is used to measure the resistance between two earth points, e.g. between an earth electrode of unknown

resistance and a known “good” ground connection such as metallic underground pipework or building steelwork.

The DET injects an a.c. current of known magnitude into the system under test and measures the voltage developed across it

as shown in Figure 3. The system resistance is a simple ratio as per Ohm’s Law, i.e. R=V/I.

Figure 3: schematic for two-terminal resistance measurement

The DET instruments automatically link the C1-P1 and C2-P2 terminals when a two-terminal test is selected

Principle of operation (three-terminal resistance measurement)

The classic “fall of potential” test is used to accurately measure the resistance of an earth electrode using auxiliary stakes

driven into the soil, which form a circuit for the test current injection and voltage measurement as used for the two-terminal

method.

The DET injects an a.c. current of known magnitude into the system under test and measures the voltage developed across

it as shown in Figure 4. The system resistance is a simple ratio as per Ohm’s Law. In this case, the potential stake is moved by

fixed increments in a straight line between the electrode under test and the current stake. At each location, the resistance is

calculated as R=V/I. A graph of resistance versus potential stake position is plotted and the resistance of the electrode under

test is taken to be the point at which the curve is flattest.

Empirical testing has shown that with suitably positioned stakes, this method can be shortened by placing the potential stake

at a distance of approximately 62% between the electrode under test and the current stake, i.e. at A = 0.62 x B.