GB

1.

IMPORTANT

1.1. Read these safety instructions carefully in addition to the instructions for use, operation and maintenance. Keep them in a safe place for

consultation following use.

1.2. This air hydraulic jack has been designed for use in the elevation of cars and lorries. Any other application beyond the conditions established for

use of this jack will be considered inappropriate.

1.3. Handle the jack correctly and ensure that all parts are in good condition prior to its initial and subsequent uses and that no parts are missing.

Otherwise, do not use the jack and contact your nearest manufacturer, supplier or technical service.

1.4. Operation and maintenance of the jack should only be performed by authorised persons, having read carefully and understood the contents of

this manual.

1.5. Do not modify the jack in any way.

1.6. Non-compliance with these instructions may result in injury or damage to the user, the jack or the load to be lifted.

1.7. The manufacturer accepts no responsibility for the improper use of the jack.

2.

SAFETY INSTRUCTIONS

2.1. The load to be lifted should never exceed the rated capacity of the jack.

2.2. The jack should be supported on a solid, level and horizontal surface to avoid any sinking. It

should be well illuminated and free of unnecessary materials.

2.3. Ensure that there are no passengers inside the vehicle to be lifted and non essential persons

should keep a safe distance from the working area. The engine should be switched off and the

hand brake applied. Use safety stands if necessary.

2.4. The air supply hose should not be worn and connections should be in good condition. Keep the

hose clean and away from heat, dirty areas or sharp edges and do not bend it.

2.5. Position the jack under the vehicle manufacturer’s recommended lifting points, which should be

stable and centred over the jack saddle. These points will be free from grease or dirt. All off-

centred loads may produce risks.

2.6. The jack should be positioned so as to avoid the need for the operator to introduce any part of

his/her body underneath the vehicle. Never work under a raised vehicle without previously

supporting it with mechanical stands or other appropriate methods.

2.7. During lifting and lowering operations, all possible precautions should be taken to avoid

movement of the vehicle load. Ensure that there are no persons or obstructions underneath the

vehicle prior to lowering.

2.8. The operator should be able to observe the lifting device and the load during all movements. In

the presence of dangerous conditions, such as movement of the vehicle, etc, the lifting or

lowering process must be interrupted.

2.9. The jack is a lifting device and should never be used to support or move the vehicle. To perform

any operation underneath the vehicle, first support it using the appropriate mechanical stands.

The handle and wheels with which these devices are equipped should only be used for

positioning under the load and moving the device from one place to another. Check that the

wheels rotate freely.

2.10. IMPORTANT Never use another extension lead than that which the jack is fitted with, which is

used to optimize the hydraulic flow.

2.11. Disconnect the air supply hose from the connector located in the handle, once the operation is

completed and prior to carrying out any maintenance work.

2.12. As an additional safety measure against overload, the jack is fitted with an overload valve, set at

the factory. This valve should not be tampered with under any circumstances.

3.

ASSEMBLY, USE AND OPERATION

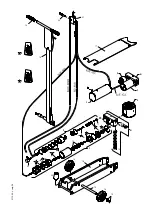

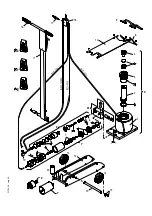

3.1. Before operating the jack, a small assembly operation is required, consisting of: Removing the upper cover (1),

removing the metal rod (A) and connecting the blue plastic tube which is provided disconnected from the

factory (Fig. 1). Place the jack handle in position (4) and secure the bolt (26) and its washer (27), which are

included in a kit as indicated (Fig. 3). Replace the cover (1).

3.2. The handle has four positions: Foldable for transportation and packing (1). Out of operation (2). Movement (3).

In operation or horizontal (4). Each position

is achieved by disengaging the trigger lever (1, Fig. 4). The

purpose of the handle is to position the jack or simplify its movement. Do not exert any pressure on the

handle.

3.3. Should the jack need to be packaged for transportation, remove the screw (26) and the washer (27) and move

the handle to position (1, Fig.2)

3.4. It is essential that an air filter-lubricator unit is installed (Fig.5), which is drained daily.

3.5. Drain the compressor daily. Poor air quality damages essential parts for the proper operation of the jack.

3.6. Prior to connecting the air supply hose (3), it is necessary to check that the control lever (2) is in the OFF

position (Fig.4). The air hose should have the same section as that of the connector (3). If unusually long hoses

are used, the air pressure should be increased.

3.7. Ensure that the same air pressure is going to be maintained during operation. Optimum performance of this jack

is obtained with a pressure of 7-10kg/cm2 and a minimum air flow of 280 l/min.

3.8. A final operation to be performed prior to using the jack is the elimination of any air that may have entered the

hydraulic system during transportation. With the air hose connected (3), push the control lever (2, Fig.4)

towards the DOWN position, holding it there for some seconds. Move the control lever to the UP position to

complete a load free lifting cycle. Move the control lever (2) to the DOWN position to retract the pistons and

hence check that the lowering action is performed steadily without any jerking movements. If the lowering action

is unsteady, repeat the cycle until the lowering of the pistons is completed in a steady and uniform way. This will

show that the draining operation has been successfully completed.

3.9. Now the jack is ready for operation.

3.10. Lifting Positioning the jack under the lifting point of the vehicle, and following all of the safety instructions

described, the lifting operation is performed by moving the to lever control (2, Fig.4) to the UP position and

holding it there until the vehicle has been lifted to the desired height. Immediately place metal stands or another

appropriate method to support the elevated vehicle.

3.11. Lowering Check that there are no obstacles or people underneath the vehicle. Once the operation is

1

2

3

4

26

27

Fig.2

Fig.3

Fig.3

Fig.3

1

2

3

A

UP

off

Fig. 4

DOWN

Fig. 1

1

A

A

1