- 4 -

OPERATION

Introduction

This parts manual contains only standard parts. Variations

of these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Before Starting & Operating

• Operating VEU creates a possible source of ignition for

flammable gas plume. BE CERTAIN ATMOSPHERE IS

SAFE BEFORE OPERATING THIS MACHINE!

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

• Know how to STOP the machine in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe

distance from any moving parts or high suction areas.

• OIL LEVEL - Check the oil level in the engine. For more

information see “Lubrication” under the respective

engine’s “Owners Manual” or the Maintenance section of

this manual.

• ENGINE AIR CLEANER - Check to ensure element is in

good condition and properly installed.

• BLOWER AIR CLEANER - Check to ensure element is

in good condition and properly installed

• FUEL SUPPLY - The engines on MBW equipment

require an automotive grade of clean, fresh, diesel fuel.

• FUEL FILTER - If clogged or damaged, replace.

• GAS SENSOR - Be familiar with operation of gas sensor.

Refer to sensor manual. Be certain that the sensor has

been calibrated and is in working order. MBW

recommends the sensor be calibrated at least every 3

months.

Assembling Probes

1.

Place probes into ground

2.

Connect probes to VEU with hose assemblies.

Note

:

The MBW VEU probes can be connected to the

VEU in many ways. Each utility should develop

their own best practice to make the connections.

To avoid a significant pressure drop, MBW

recommends not connecting more then 6 (six)

probes to a single 1-1/2” branch hose. If more

probes are desired, they should be connected to a

new branch line coming off the VEU.

3.

Open all valves on VEU probes.

4.

Cap all open hose ends with CAM-Loc plugs/caps.

5.

Close unused manifold valves on VEU.

6.

Fully open Air-Bypass valve before starting engine.

Starting Engine

For detailed instructions refer to the engine “Owner’s

Manual”.

WARNING

Ensure gas concentration in work area is safe for

open ignition sources. DO NOT use machine in

areas that are unsafe.

WARNING

Ensure sampling line and cup are in place at

bottom of sensor. DO NOT use machine if the

sampling line is not connected.

7.

Plug sensor/vacuum combo plug into socket on

canister housing.

Note: Engine will NOT run without sensor plugged in.

8.

When power is supplied to the sensor stand

assembly the sensor will start a warm up cycle.

This

cycle will take approximately 4 minutes and

engine will NOT RUN until the “Wait to Start” light

turns off.

9.

Open bypass valve fully, close all vacuum supply

valves on canister, open valves on probes.

10. Turn toggle switch to “ON”.

11. Press glow plug button if engine is cold. Glow plugs

will cycle each time button is pressed.

12. Press engine start button to engage starter.

13. Allow engine to warm up for one or two minutes.

Operating

1.

Ensure proper operation of gas sensor.

2.

Run engine speed up to approximately 30%.

Содержание VAPOR EXTRACTION UNIT

Страница 13: ...10 This page intentionally left blank...

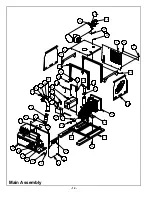

Страница 15: ...12 Main Assembly...

Страница 17: ...14 5 3 7 7 Canister and Blower Assembly...

Страница 19: ...16 Sensor Stand Assembly...

Страница 21: ...18 7 6 7 6 Control Assembly...

Страница 23: ...20 5 5 1 7 5 Plug Assembly...

Страница 25: ...22 Door Assembly...

Страница 27: ...24 Engine Assembly...

Страница 29: ...26 Probe and Hose Assemblies...

Страница 32: ...29 NOTES...