- 6 -

MAINTENANCE

WARNING

Always exercise the stopping procedure before

servicing or lubricating the unit.

After servicing the unit, replace and fasten all

guards, shields, and covers to their original

positions before resuming operation.

CAUTION

Always verify fluid levels and check for leaks after

changing fluids.

Do not drain oil onto ground, into open streams,

or down sewage drains.

Maintenance Schedule

1.

Check all hardware after the first 5 hours of use, then follow the maintenance schedule.

2.

Calibrate sensor before using VEU. Sensor is NOT calibrated from the factory.

Engine Maintenance

Refer to the engine owner’s manual for maintenance

intervals and procedures.

• Check the engine air cleaner element at least once daily.

• Check the engine oil level by removing the dipstick (the

engine must be level). The oil level should be between

the marks on the dipstick. See the “Check Engine Oil”

section of the engine “Owner’s Manual” for information.

• See the “Change Engine Oil” section of the engine

“Owner’s Manual” for information on the oil change

intervals.

• Disconnect battery for long term storage.

Draining Fuel Tank

Refer to Main Assembly, page 12.

1.

Remove brackets holding tank.

2.

Loosen hose clamps and remove hoses.

3.

Drain until all water and contaminates are cleared.

4.

Properly dispose of drained fuel.

Engine Speed

Engine speed is factory set according to the speed listed in

the Recommended Engine RPM, page 3 of this manual.

Refer to the engine owners manual for procedure on setting

operating speed if necessary.

Blower Maintenance

The blower contains both a grease lube system and an oil

bath system. Refer to blower manual for service

instructions.

Cleaning Blower Air filter

Refer to Canister and Blower Assembly, page 14.

1.

Remove outer knob (# 18) and outer door (#6).

2.

Remove inner knob (# 17) and Inner door (# 28).

3.

Slide filter out of housing.

4.

Remove prefilter and wash with clean warm water.

SYSTEM

MAINTENANCE

DAILY

EVERY 25

HOURS

EVERY 300

HOURS

YEARLY

Vac air filter

Check and clean

X

Engine

Refer to engine operator/owner manual

X

Fuel

drain tank

X

Hardware

Check and tighten as needed

1

X

X

In Line Fuel Filter

Replace

X

X

Blower

Refer to Blower operators/owners

manual

X

Gas Sensor

Calibrate

2

(Refer to Gas Sensor manual)

4x

Test

X

Содержание VAPOR EXTRACTION UNIT

Страница 13: ...10 This page intentionally left blank...

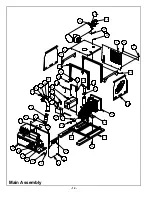

Страница 15: ...12 Main Assembly...

Страница 17: ...14 5 3 7 7 Canister and Blower Assembly...

Страница 19: ...16 Sensor Stand Assembly...

Страница 21: ...18 7 6 7 6 Control Assembly...

Страница 23: ...20 5 5 1 7 5 Plug Assembly...

Страница 25: ...22 Door Assembly...

Страница 27: ...24 Engine Assembly...

Страница 29: ...26 Probe and Hose Assemblies...

Страница 32: ...29 NOTES...