Operating Instructions MBA888

Operating Instructions MBA888

11/2017/Item No. 8001705

Page 3/6

MBA Instruments GmbH

5.

Function and switching behaviour

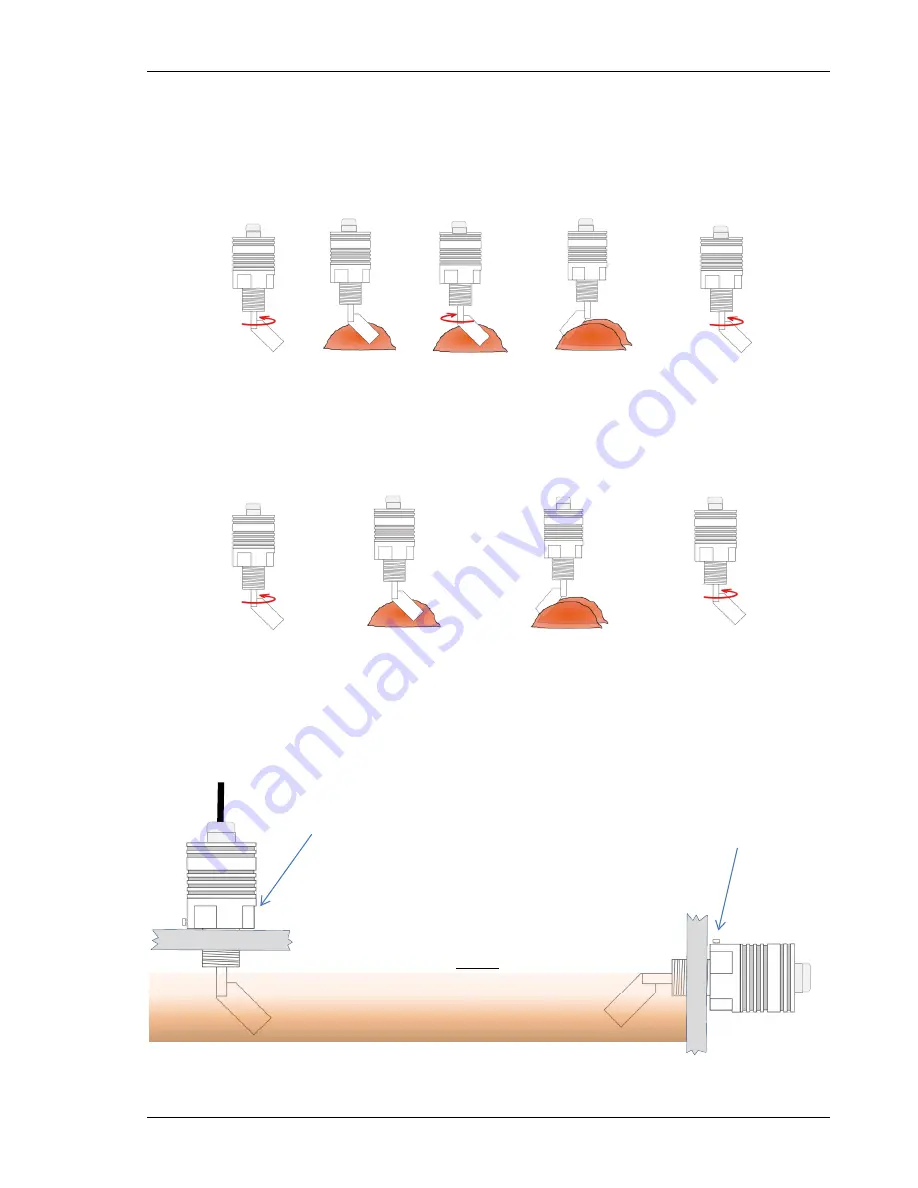

A motor rotates a shaft, with a vane secured to the end of the shaft. If the vane strikes the bulk material, a

torque builds up until the shaft stops rotating. The shaft then reverses its direction of rotation. The signal

switches when shaft rotation is blocked in both directions.

"Quick Switch" device design:

On this version, the MBA888 checks whether shaft rotation is blocked in one direction only. This means that the

very fast switching allows the device to be used as a "Full" indicator

:

6.

Installation

The MBA888 is screwed into a suitable sleeve with the process connection. The installation position must be selected

such that the vane at the end of the shaft is covered by the bulk material at the switching point. Light-weight or fluid

bulk material must cover the vane a little more than is the case with heavy bulk material. Measurement is

independent of the MBA888's installation position.

2. Shaft

stops

3. Shaft

turns CW

4. Shaft stops

Signal switches: "full"

1. Shaft

turns CCW

+3 s

+3 s

5. Shaft turns CCW

Signal switches: "empty"

+3 s

2. Shaft

stops

3. Shaft stops

Signal switches: "full

1. Shaft

turns CCW

+1s

4. Shaft stops

Signal switches: "empty"

+1s

light-weight bulk mat.

medium-weight bulk mat.

heavy bulk material

Examples

Washing powder

Barley

Plastic granulate

Quartz sand

Gravel

4 Mounting surfaces for

65 mm width across flats

Tightening torque: 300 Nmm

Screw-in sleeve: G1.5" to ISO 228/1

Container

wall

Equipotential bonding:

for equipotential-bonding

screw with eyelet, d = 4 mm

Container top section