3

* "Attachment surface" refers to the doors and/or bumper, and "part" refers to supplementary parts.

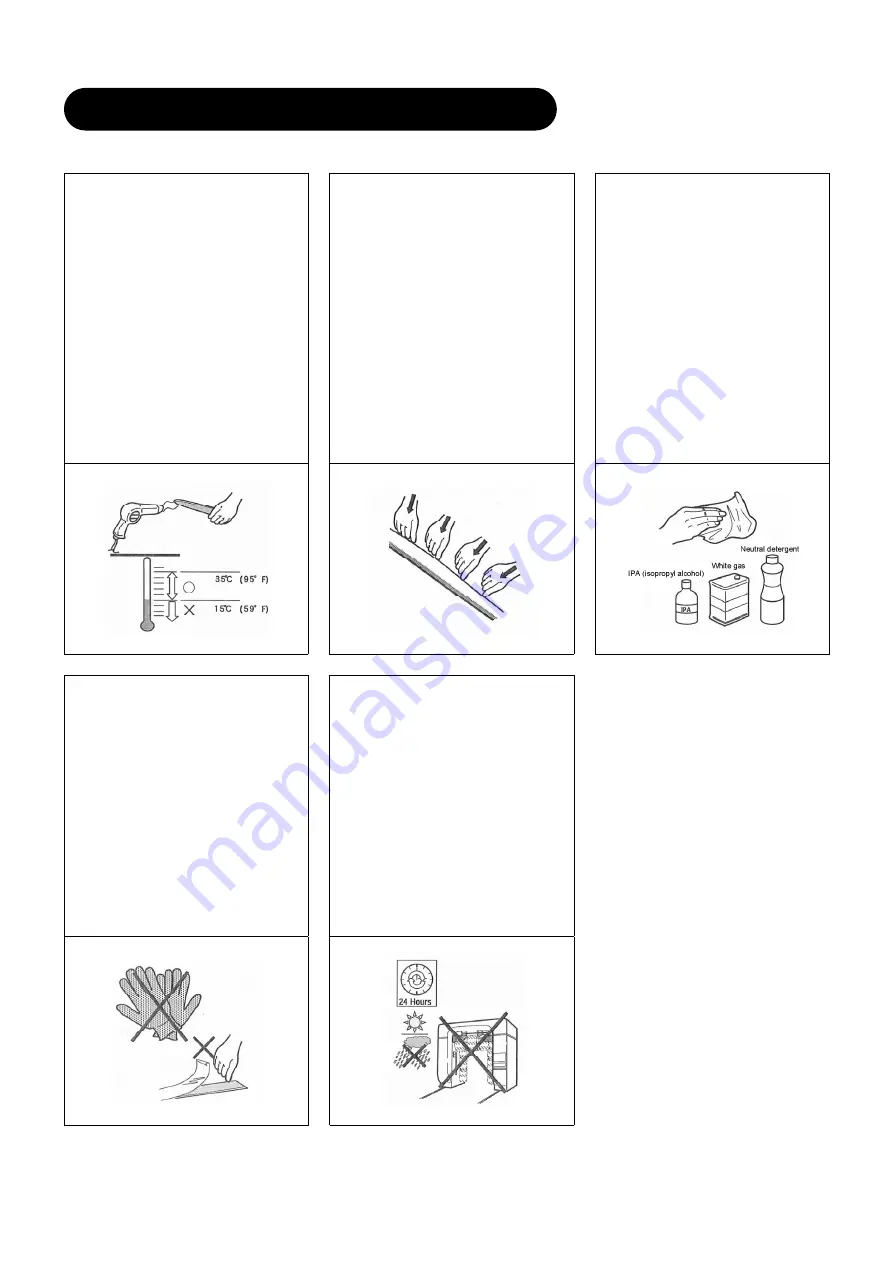

1. Avoid working in ambient

temperatures of less than 15 °C.

The stickiness of the adhesive

depends on the softness of the resin,

and so the adhesive loses its

stickiness and the adhesive strength

drops at low temperatures (15 °C or

less).

Accordingly, avoid carrying out work in

places where the ambient

temperature is less than 15 °C.

If working in places where the ambient

temperature is less than 15 °C, you

should heat the attachment surface

and the part until they are warm

enough.

2. Attach evenly.

In order to ensure that the adhesive

surface of the double-sided tape

attaches correctly, it is necessary to

press the adhesive surface of the tape

against the attachment surface with a

uniform force overall. In particular,

press down sufficiently on the

double-sided tape when the ends of

the tape and the attachment surface

are curved.

3. Clean the attachment surface.

If there is any dirt, grease or other

contamination on the attachment

surface, they may become attached

to the double-sided tape, causing a

drop in the adhesive strength of the

double-sided tape.

You should clean the attachment

surface before attaching the

double-sided tape.

As a general rule, use neutral

detergent for interior surfaces, and

use IPA (isopropyl alcohol) or white

gas for exterior surfaces.

4. Avoid getting the tape dirty.

If you touch the adhesive surface

while working, oil from your hands can

get onto the adhesive and cause a

drop in the adhesive strength of the

double-sided tape.

In addition, when working while

wearing gloves, fibers and dirt from

the gloves may become attached to

the adhesive.

Take care to avoid contaminating the

adhesive surface of the double-sided

tape.

5. Handling after attaching the

tape

After the tape has been attached, the

adhesive strength will not stabilize

until 24 hours have passed, so do not

drive or wash the vehicle or leave it

exposed to rain for 24 hours.

In addition, never remove and

reattach the double-sided tape once

the product has been installed, as this

will result in a dramatic drop in

adhesive strength.

4.

DOUBLE-SIDED TAPE ATTACHMENT