3

InSTAllATIon REquIREmEnTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Flat-blade screwdriver

■

#2 Phillips head

■

screwdriver

Adjustable wrench that

■

opens to 1" (25 mm) or

hex-head socket wrench

(for adjusting dryer feet)

Level

■

Wire stripper (direct wire

■

installations)

Utlility knife

■

1/4" nut driver

■

(recommended)

Vent clamps

■

Caulking gun and

■

compound (for installing

new exhaust vent)

Tin snips (new vent

■

installations)

Tape measure

■

Pliers

■

Parts supplied:

Parts package is located in dryer drum. Check that all parts

are included.

Parts needed:

Check local codes. Check existing electrical supply and venting,

and read “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

Mobile home installations require metal exhaust system

hardware, available for purchase from the dealer from whom you

purchased your dryer. For further information, please reference

the “Assistance or Service” section of the Dryer

User Instructions.

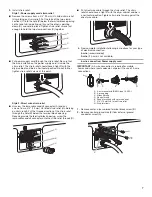

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

A UL listed 30-amp power supply cord, rated 120/240 volt

■

minimum. The cord should be type SRD or SRDT and be at

least 4 ft. (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

A UL listed strain relief.

■

location Requirements

You will need:

A location allowing for proper exhaust installation.

■

See “Venting Requirements.”

A separate 30 amp circuit.

■

If you are using power supply cord, a grounded electrical

■

outlet located within 2 ft. (610 mm) of either side of dryer.

See “Electrical Requirements.”

A sturdy floor to support the total weight (dryer and load)

■

of 200 lbs. (90.7 kg). The combined weight of a companion

appliance should also be considered.

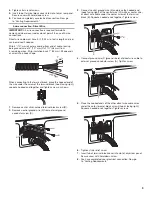

Level floor with maximum slope of 1" (25 mm) under entire

■

dryer. (If slope is greater than 1" [25 mm], install Extended

Dryer Feet Kit, Part Number 279810.) If not level, clothes

may not tumble properly and automatic sensor cycles may

not operate correctly.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

4 Leveling legs