13

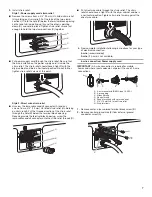

level Dryer

Check the levelness of the dryer. Check levelness first side to

side, then front to back.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again

for levelness.

noTE:

It might be necessary to level the dryer again after it is

moved into its final position.

Connect Vent

1.

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Check that the vent is secured

to exhaust hood with a 4" (102 mm) clamp.

2.

Move dryer into its final location. Do not crush or kink vent.

3.

Once the exhaust vent connection is made, remove the

corner posts and cardboard.

Complete Installation

1.

Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2.

Check that you have all of your tools.

3.

Dispose of/recycle all packaging materials.

4.

Check the dryer’s final location. Be sure the vent is not

crushed or kinked.

5.

Check that the dryer is level. See “Level Dryer.”

6.

For power supply cord installation, plug into an outlet.

For direct wire installation, turn on power.

7.

Remove the protective film on the console and any tape

remaining on the dryer.

8.

Wipe the dryer drum interior thoroughly with a damp cloth

to remove any dust.

9.

Read “Dryer Use” in the Dryer User Instructions.

10.

Set the dryer on a full heat cycle (not an air cycle) for

20 minutes and start the dryer.

If the dryer will not start, check the following:

Controls are set in a running or “On” position.

■

Start button has been pushed firmly.

■

Dryer is plugged into an outlet and/or electrical supply

■

is on.

Household fuse is intact and tight, or circuit breaker has

■

not tripped.

Dryer door is closed.

■

Determine vent path:

Select the route that will provide straightest and most direct

■

path outdoors.

Plan the installation to use the fewest number of elbows and

■

turns.

When using elbows or making turns, allow as much room

■

as possible.

Bend vent gradually to avoid kinking.

■

Use as few 90° turns as possible.

■

Determine vent length and elbows needed for

best drying performance:

Use following Vent system chart to determine the elbow and

■

hood combinations acceptable to use.

noTE:

Do not use vent runs longer than those specified

in the Vent System Chart. Exhaust systems longer than those

specified will:

Shorten life of dryer.

■

Reduce performance, resulting in longer drying times

■

and increased energy usage.

The Vent system chart provides venting requirements that will

help achieve best drying performance.

Vent System Chart

number

90° turns or

elbows

Type of vent

Box/louvered

hoods

Angled hods

0

Rigid metal

64 ft. (20 m)

58 ft. (17.7 m)

1

Rigid metal

54 ft. (16.5 m)

48 ft. (14.6 m)

2

Rigid metal

44 ft. (13.4 m)

38 ft. (11.6 m)

3

Rigid metal

35 ft. (10.7 m)

29 ft. (8.8 m)

4

Rigid metal

27 ft. (8.2 m)

21 ft. (6.4 m)

Vent System Chart (long Vent models only)

number 90° turns

or elbows

Type of vent

Box, louvered,

or angled

hoods

0

Rigid metal

120 ft. (36.6 m)

1

Rigid metal

110 ft. (33.5 m)

2

Rigid metal

100 ft. (30.5 m)

3

Rigid metal

90 ft. (27.4 m)

4

Rigid metal

80 ft. (24.4 m)

5

Rigid metal

70 ft. (21.3 m)

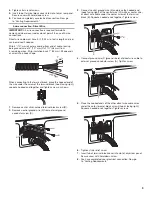

Install Vent System

1.

Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2.

Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (102 mm) clamp.

3.

Run vent to dryer location. Use the straightest path possible.

See “Determine vent path” in “Plan Vent System.” Avoid 90º

turns. Use clamps to seal all joints. Do not use duct tape,

screws, or other fastening devices that extend into the interior

of the vent to secure vent, because they can catch lint.