8 de 10

104 S. 8th Ave. Marshalltown, IA Teléfono 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.MARSHALLTOWN.com

WS2860

OPERACIÓN DEL PRODUCTO

MÉTODO DE TIRO RECTO: MÉTODO UNO DE OPERACIÓN EN HORMIGÓN HÚMEDO

Niveles de asentamiento de 5 (125 mm) o más, mantenga una sobrecarga de 1 a 2 pulgadas (2.5 a 5 cm)

Cuando trabaje con hormigón húmedo, arranque la enrasadora Spin Screed®, apriete la palanca del acelerador y jale la enrasadora

lentamente sobre el hormigón mientras los niveladores mantienen una sobrecarga de hormigón de aproximadamente 2 pulg (5 cm)

enfrente de la enrasadora. Después de avanzar 6 a 8 pies (2 a 2.5 m), permita que la enrasadora giratoria Spin Screed® se mueva

lentamente hacia atrás sobre el hormigón recién enrasado. Esta pasada lenta hacia atrás empuja hacia abajo el agregado que se quedó en

la superficie al tiempo que eleva la pasta a la superficie. Después de retroceder sobre la sección vertida, desacelere la Spin Screed® y jale

la enrasadora hacia atrás al área donde se ha colocado más hormigón. Comience a enrasar de nuevo. Con hormigón más húmedo que un

asentamiento de 5 pulg (125 mm), pasar la enrasadora por la superficie del hormigón una segunda vez con el motor funcionando producirá

una superficie más plana con suficiente pasta para pasar la aplanadora. Verifique las superficies preparadas por la Spin Screed® y ajuste

su técnica a fin de producir la superficie deseada para pasar la aplanadora.

MÉTODO DE BULTO Y EXTENSIÓN: MÉTODO DOS DE OPERACIÓN DEL HORMIGÓN RÍGIDO

Niveles de asentamiento de 3 a 4 pulgadas, manteniendo una sobrecarga de 2.5 a 3.5 pulgadas

Con hormigón rígido, pasar la enrasadora Spin Screed® sobre el hormigón produce una superficie áspera que es difícil de alisar con

aplanadora. Para obtener mejores resultados, use la técnica de “bulto y extensión”. Comience jalando la palanca del acelerador para

arrancar la Spin Screed® y abulte suavemente una sobrecarga de 2 a 3 pulg (5 a 7.5 cm) con la Spin Screed® haciendo que avance unas

pulgadas y luego dejándola replegarse 4 a 6 pulga (10 a 15 cm). Mueva de nuevo la enrasadora Spin Screed® hacia adelante. Continúe con

la técnica de “bulto y extensión” hasta que haya avanzado 6 a 8 pies (2 a 2,5 m), luego deje que la enrasadora Spin Screed® se mueva

hacia atrás lentamente sobre el hormigón recién enrasado con la Spin Screed® aún funcionando. Esta pasada lenta hacia atrás empuja

hacia abajo el agregado que se quedó en la superficie al tiempo que eleva la pasta a la superficie. Después de retroceder sobre la sección

vertida, apague la Spin Screed® y jale la enrasadora hacia atrás al área donde se ha colocado más hormigón. Comience a enrasar de nuevo.

La sección enrasada está lista para aplanarse, lo cual debe llevarse a cabo inmediatamente. Cuando se enrasa hormigón más rígido, jalar

la Spin Screed® hacia adelante una segunda vez tiende a eliminar la capa de pasta que se ha trabajado en la superficie y hace que esta sea

más difícil de aplanar y acabar.

IMPORTANTE

Asegúrese de que la enrasadora Spin Screed® se limpie inmediatamente después de usarse a fin de evitar que el hormigón se endurezca

en el eje impulsor del motor, el alojamiento del motor, las juntas del mango o en el tubo.

La limpieza del motor se debe llevar a cabo soplando aire comprimido y lavándolo manualmente, evitando que ingrese agua cerca del

carburador. Se recomienda el uso de lavadoras a presión para limpiar el tubo, pero NO deben usarse para limpiar el motor ni la caja de

engranajes.

Spin Screed Techniques of Operation:

The Spin Screed power head has been designed with a reversing switch. The power head can be made to operate on

either side of the pour moving in either direction.

As with any electric tool, proper operating voltage is essential. Always use heavy-duty properly grounded extension

cords and follow the directions associated with the spin motor for maximum length and gauge of extension cords.

The spin motor draws 10 amperes of current at 120 volts when fully loaded. A portable electric generator can easily

provide this voltage and current requirement if a source of 120 volt AC is not otherwise available. GFI breakers are an

OSHA requirement for tools used on the construction site. All extension cords and power cords should be inspected

and tested for defects before being placed into operations. Defective cords not protected by GFI breakers could lead

to death or severe injury.

The Spin Screed will handle stiff concrete having only a 3-inch slump or any larger slump that you choose to pour. We

advise that when you first start using the Spin Screed, you pour with a slump level that is consistent with your past

practices. As with any new tool you bring onto your job site, certain techniques of operation must be learned so the

quality level of work you demand can be achieved.

With wet concrete, you will probably find that the spin motor can be energized and the Spin Screed slowly pulled over

the concrete while muckers are maintaining about a two-inch surcharge of concrete in front of the screed. Once you

have advanced for 6 to 8 feet or more, you will want to allow the Spin Screed to move backward slowly over the freshly

screeded concrete while the Spin Screed is still spinning. This slow backward pass pushes any concrete aggregate

that may be above the surface down into the surface while at the same time bringing paste to the surface. Once you

have backed over the section just poured, you will want to turn off the spin motor and simply pull the screed back to

the area where more concrete has been placed and begin the screeding operation again. With concrete wetter than a

5 inch slump, you may find that pulling over the concrete surface a second time, while the spin motor is still running,

will produce a flatter surface with sufficient paste for bull floating. The general rule is to examine the surface prepared

by the Spin Screed and adjust your screeding technique to produce the most desirable surface for bull floating.

1-888-329-6039 • www.spinscreed.com

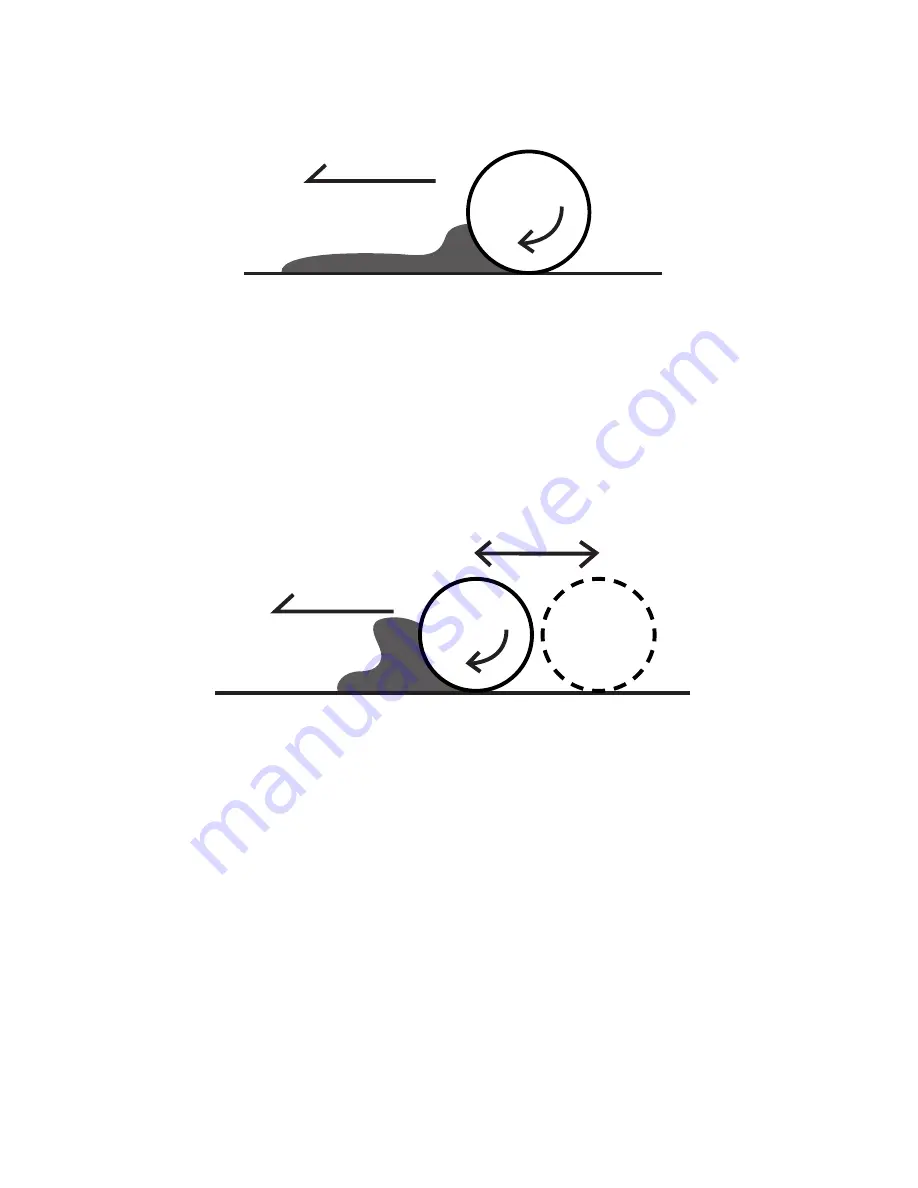

Wet Concrete

Operating Method No. 1:

Slump levels of 5 inches

or more. Maintain 1 to 2

inch surcharge.

Stiff Concrete

Operating Method

No. 2:

Slump levels of 3 to

4 inches. Maintain

2.5 inch to 3.5 inch

surcharge.

STRAIGHT PULL

BUMP AND RUN

(OVER)

Spin Screed Techniques of Operation:

The Spin Screed power head has been designed with a reversing switch. The power head can be made to operate on

either side of the pour moving in either direction.

As with any electric tool, proper operating voltage is essential. Always use heavy-duty properly grounded extension

cords and follow the directions associated with the spin motor for maximum length and gauge of extension cords.

The spin motor draws 10 amperes of current at 120 volts when fully loaded. A portable electric generator can easily

provide this voltage and current requirement if a source of 120 volt AC is not otherwise available. GFI breakers are an

OSHA requirement for tools used on the construction site. All extension cords and power cords should be inspected

and tested for defects before being placed into operations. Defective cords not protected by GFI breakers could lead

to death or severe injury.

The Spin Screed will handle stiff concrete having only a 3-inch slump or any larger slump that you choose to pour. We

advise that when you first start using the Spin Screed, you pour with a slump level that is consistent with your past

practices. As with any new tool you bring onto your job site, certain techniques of operation must be learned so the

quality level of work you demand can be achieved.

With wet concrete, you will probably find that the spin motor can be energized and the Spin Screed slowly pulled over

the concrete while muckers are maintaining about a two-inch surcharge of concrete in front of the screed. Once you

have advanced for 6 to 8 feet or more, you will want to allow the Spin Screed to move backward slowly over the freshly

screeded concrete while the Spin Screed is still spinning. This slow backward pass pushes any concrete aggregate

that may be above the surface down into the surface while at the same time bringing paste to the surface. Once you

have backed over the section just poured, you will want to turn off the spin motor and simply pull the screed back to

the area where more concrete has been placed and begin the screeding operation again. With concrete wetter than a

5 inch slump, you may find that pulling over the concrete surface a second time, while the spin motor is still running,

will produce a flatter surface with sufficient paste for bull floating. The general rule is to examine the surface prepared

by the Spin Screed and adjust your screeding technique to produce the most desirable surface for bull floating.

1-888-329-6039 • www.spinscreed.com

Wet Concrete

Operating Method No. 1:

Slump levels of 5 inches

or more. Maintain 1 to 2

inch surcharge.

Stiff Concrete

Operating Method

No. 2:

Slump levels of 3 to

4 inches. Maintain

2.5 inch to 3.5 inch

surcharge.

STRAIGHT PULL

BUMP AND RUN

(OVER)