Gas Conversion Instructions

Kit Number

Description Pilot

Orifice Burner Orifice

Brass (1000-255)

Air Shutter

Hi/Lo Regulator

3927-CKLP

4634-CKLP

LP Conversion

-Millivolt-

1001-P167SI

#30

(977.167)

#46

#42

Full Open

Full Open

1001-P202SI

(0.907.202)

3927-CKNG

4634-CKNG

NG Conversion

-Millivolt-

1001-P165SI

#51

(977.165)

#29

#25

1/4”

3/8”

1001-P201SI

(0.907.201)

3927-CKLPi

4634-CKLPi

LP Conversion

-IPI-

1001-P168SI

#35

(977.168)

#46

#42

Full Open

Full Open

1002-P014SI

(0.907.014)

3927-CKNGi

4634-CKNGi

NG Conversion

-IPI-

1001-P166SI

#62

(977.166)

#29

#25

1/4”

3/8”

1002-P016SI

(0.907.016)

Refer to “

Gas Specifications Chart

” for inlet pressures and input ratings. Clock meter to verify input rate. Place conversion label as

close to converted gas control as possible. Refer to lighting instructions to verify the normal operating sequence of the ignition system.

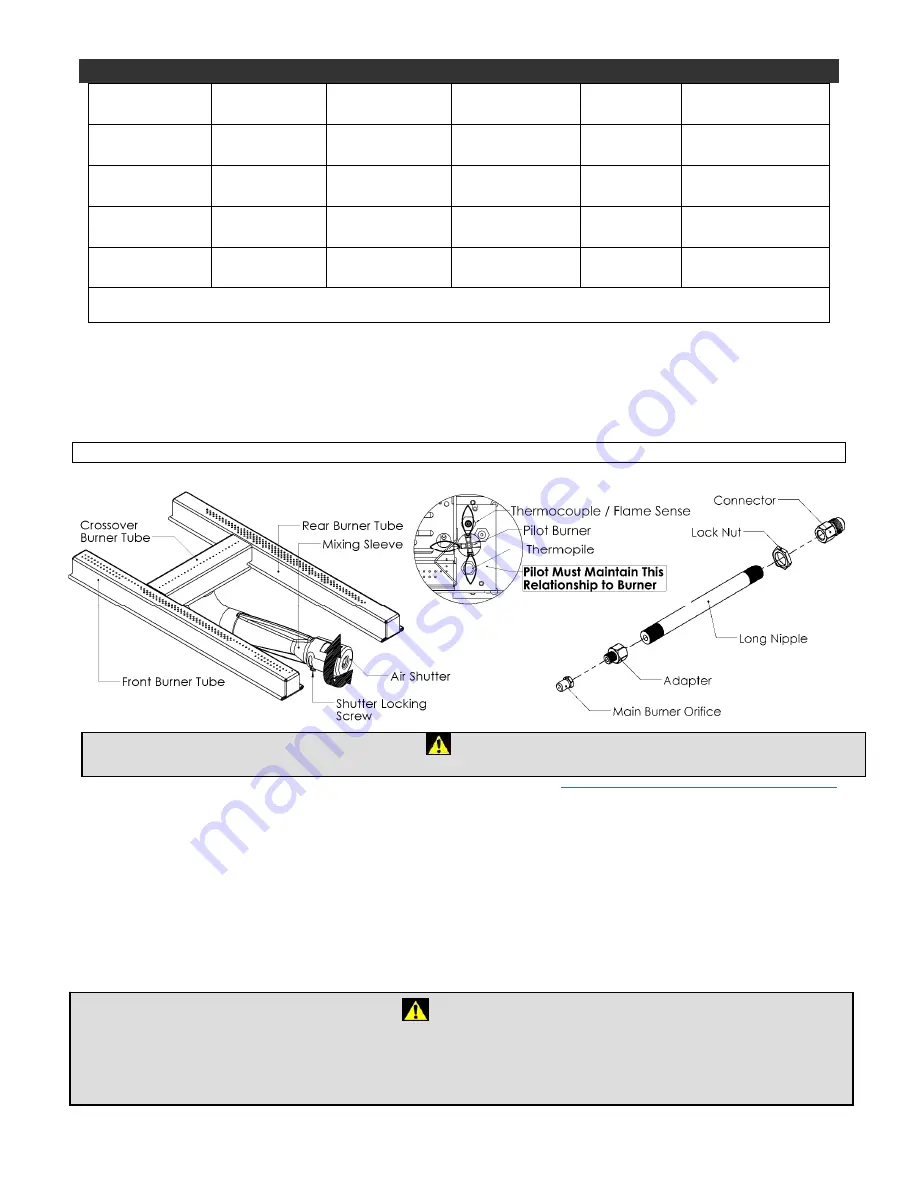

There are three main components involved in converting this appliance for use with an alternate fuel source. They are the

valve, main burner system, and pilot burner system. Improper modification of any of these components may degrade the

appliance’s performance and can lead to unsafe operation. Ensure that these adjustments are done properly.

Converting this appliance can only be done with a prescribed kit. These kits cannot be modified in any way and must be

installed in accordance to the instructions supplied. The instruction manual supplied with the kit supersedes this section of the

installation manual. For more information with regards to the kit involved consult the Parts List MQZDV3927 on

page 50.

IMPORTANT: Always check for gas leaks with a soap and water solution. DO NOT USE OPEN FLAME FOR LEAK TESTING.

Main Burner Conversion

1. Remove the burner tube from the burner system (refer to page 24).

2. To adjust the Primary Air Setting, loosen the Air Shutter Adjustment Screw and rotate the Air Shutter to the appropriate

gap position of the new fuel. A drill bit of the proper diameter or a measuring device such as a caliper maybe used to

establish the gap opening.

3. Replace the old orifice with one for the new fuel. Pipe sealing compound is required to ensure a proper seal between the

orifice and the adapter fitting.

4. For information with regards to the size of the Primary Air Setting and orifice, please refer to page 32. To reinstall the

burner tube assembly please refer to page 24 & 24.

Valve Conversion

The HI/LO diaphragm of the gas valve must be replaced to accommodate the alternate fuel source. Please follow the

instructions that accompany the conversion kit for the gas valve.

Figure 19 - Main burner fuel conversion guide.

Caution

:

The gas supply shall be shut off prior to disconnecting the electrical power, before proceeding with the conversion.

WARNING

This conversion kit shall be installed by a qualified service agency in accordance with the manufacturer's instructions and all

applicable codes and requirements of the authority having jurisdiction. If the information in these instructions is not followed

exactly a fire, explosion or production of carbon monoxide may result causing property damage, personal injury or loss of life.

The qualified service agency is responsible for the proper installation of this kit. The installation is not proper and complete until

the operation of the converted appliance is checked as specified in the manufacturer's instructions supplied with kit.

35