6

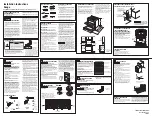

Manual Shut-Off Valve:

This installer-supplied valve must be installed in the gas service line ahead of the appliance and

regulator in the gas stream and in a position accessible in the event of an emergency.

Pressure Regulator:

Gas pressure regulator provided with the equipment must be installed when the appliance is connected

to gas supply.

All commercial cooking equipment must have a pressure regulator on the incoming service line for safe

and efficient operation, since service pressure may fluctuate with local demand. The pressure regulator

comes with the oven. Failure to install the pressure regulator will void the equipment warranty!

The regulators supplied with MARKET FORGE INDUSTRIES, INC. Ovens, have 3/4” inlet /outlet openings

and are adjusted at the factory for 5” WC (Natural gas) or 10” WC (Propane gas) depending on

customer’s ordering instructions.

Prior to connecting the regulator, check the incoming line pressure, as these regulators can only

withstand a maximum pressure of ½ PSI (14”WC). If the line pressure is beyond this limit, a step-down

regulator will be required. The arrow shown on the bottom of the regulator body shows gas flow

direction; it should point downstream to the appliance. The red air vent cap on the top regulator is part

of the regulator and should not be removed.

Any adjustments to regulators must be made only by qualified service personnel with the proper

equipment.

Connections:

Please check installer-supplied intake pipes visually and /or blow them out with compressed air to clear

any dirt particles, threading chips, or other foreign matter before installing a service line. When gas

pressure is applied these particles can clog orifices. All connections must be sealed with a joint

compound suitable for LP gas, and all connections must be tested with a soapy water solution before

lighting any pilots!

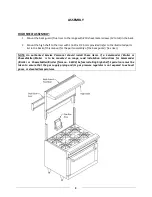

Flexible Coupling, Connectors and Casters:

For an appliance equipped with casters the installation shall be made with a connector that complies

with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or Connectors for Moveable

Gas Appliances, CAN/CGA-6.16, and a quick –disconnect device that complies with the standard for

Quick Disconnect Devices for Use with Gas Fuel, ANSI Z21.41, or Quick Disconnect Devices for Use with

Gas Fuel, CANI-6.9. Adequate means must be provided to limit the movement of the appliance without

depending on the connector and the quick-disconnect device or its associated piping to limit the

appliance movement. Restraining devices may be attached to the back frame/panel of the unit.

If legs or casters are not used, the unit must extend 2” beyond the front edge of a noncombustible curb

or platform. Broilers are for installation in non-combustible locations only.

Before lighting, check all joints in the gas supply line for leaks.

DO NOT USE AN OPEN FLAME TO CHECK FOR LEAKS!

Putting an open flame beside a new gas connection is extremely dangerous.

Содержание R-R10

Страница 6: ...5 Dimensions and Burner Options ...

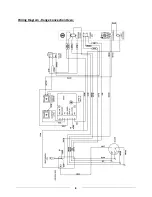

Страница 9: ...8 Wiring Diagram Range Convection Oven ...

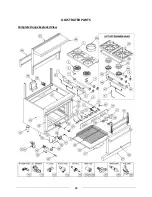

Страница 14: ...13 ILLUSTRATED PARTS Complete Range Exploded View ...

Страница 18: ...17 Griddle Radiant Broiler and Raised Griddle Exploded Views ...

Страница 21: ...20 Convection Oven Exploded View ...