SEDM - Smoke extraction damper - multi

Page 24

Version 2022-12-20

TPM 156/22

Placement and Assembly

■

Dampers are designed to remove heat and combustion

products (e.g. smoke) from fire compartments according

EN 12101-8.

■

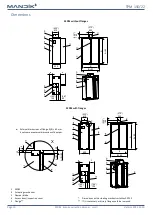

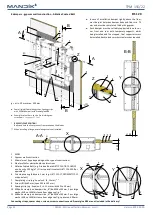

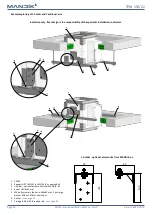

Dampers can be installed with the actuator on the top,

bottom or either side.

■

If Actuator is installed on the bottom take care when

removing the actuator housing cover.

■

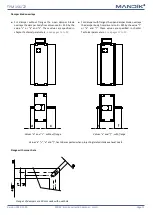

To provide needed access space to the control device, all

other objects must be situated at least 350 mm from the

control parts of the damper.

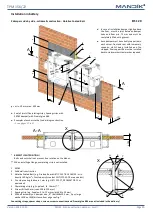

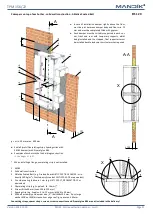

The distance between the smoke damper and the construction

■

minimum distance 200 mm between dampers installed in the duct;

■

minimum distance 75 mm between damper and construction (wall/ceiling).

■

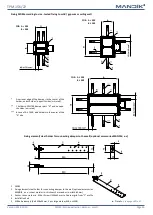

This is the BS EN1366-2 test standard distances. They

are considered as minimum. Actual location should be

based on wall manufacturers requirements.

■

Always consult the wall manufacturers specific guide-

lines for deflection heads, penetration size, location to

other services, fire stopping and load bearing capacity.

■

With smoke control ducting then refer to duct manu-

facturers tested parameters for spacing & pattress re-

quirements.

■

No other services should pass through the dampers

building work opening.

■

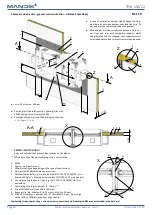

During installation the damper blade must be in position

“CLOSED”. The damper body should not be deformed in

the course of installation.

■

Once the damper is built in, its blade should move freely

and not rub against the body of the damper or duct during

operation.

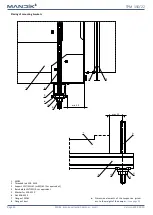

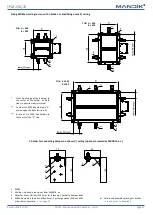

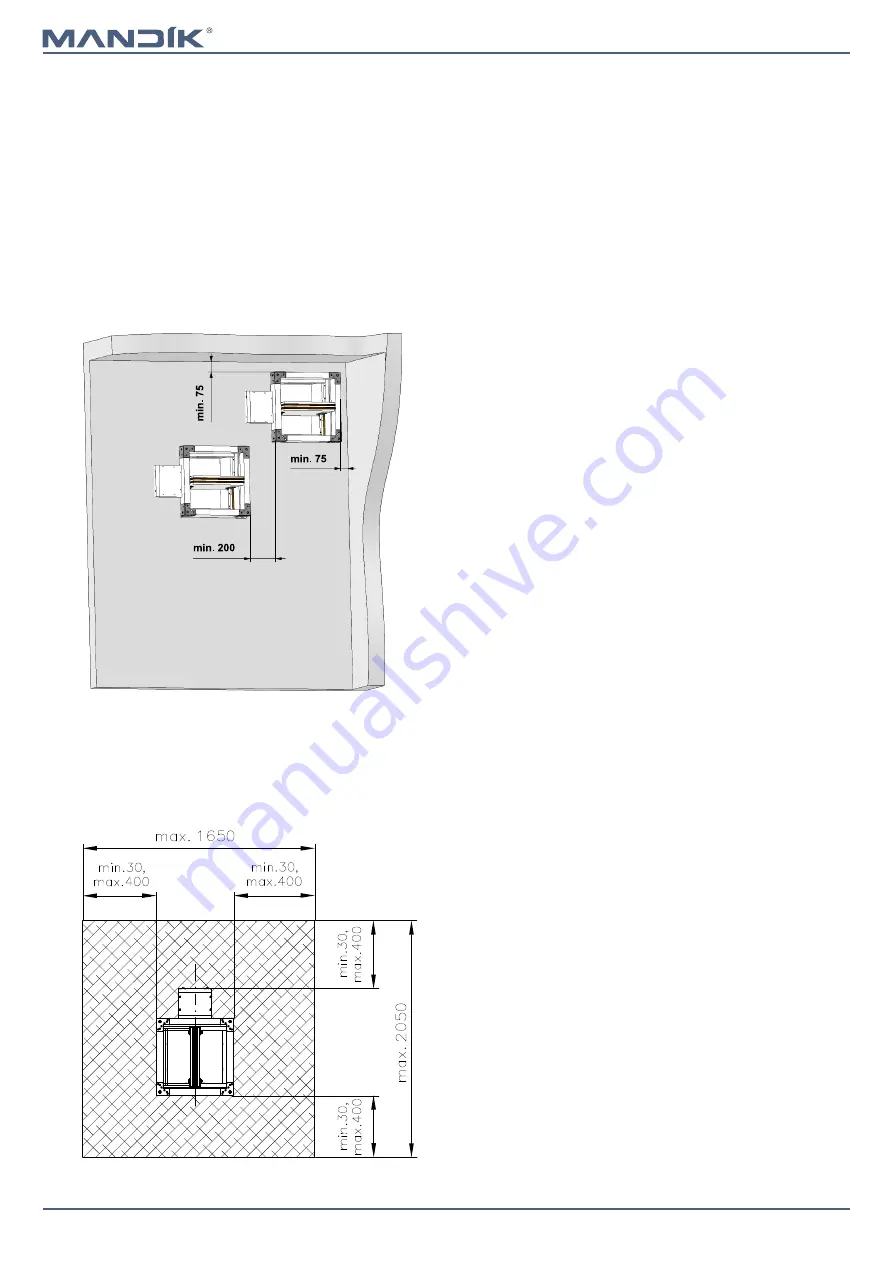

Dimensions of installation opening

Installation opening Ablative Coated Batt