18

Dimensions are checked using common gauges according to the standards for not tolerated dimensions applied in air conditioning

sector. In-process inspections of parts and main dimensions are carried out according to drawing documentation.

After workshop assembly 100% functional test of closing device and electric elements is carried out.

Dampers are transported in bulk in covered transport means without direct weathering effects, without strong impacts and ambient

temperature must not 50°C. If customer requires other packaging it will not be returnable and price of such a packaging

is not included in the price.

Dampers shall be considered as accepted unless it is specified otherwise in particular order.

During handling within transport and storage dampers must be protected from mechanical damage. Dampers must be stored in

roofed objects with environment without aggressive vapours, gases and dust. Temperature scope in such objects must be within

- 5 to + 40°C and relative humidity max. 80 %.

The delivery means complete Multi blade fire damper and warranty card with inspection stamp (warranty card is attached to invoice).

Manufacturer provides 24 month-guarantee from dispatching date.

Guarantee for FDML damper provided by the manufacturer becomes void if any non professional handling with closing mecha-

nism and control device by not trained persons has been performed, after dismantling electrical elements, i.e. limit switches, servo

drives, optical smoke detectors and thermo-electric actuators. Guarantee also becomes void when damper is used for other than

intended use and in working conditions not allowed by this standard or if it was damaged mechanically during handling.

If any damage occurs during the transport it is necessary to make a report during unloading with transport company for future claims.

Assembly, maintenance and serviceability checks may be performed only by persons capable for such activities, i.e. "AUTHORIZED

PERSONS" trained by the manufacturer. Training is organised and carried out by MANDÍK, a.s. who issues "CERTIFICATE" on

professional qualification with validity 5 years and its prolongation must be provided by "AUTHORIZED PERSON" itself directly at

trainer premises.

When terminates validity of the CERTIFICATE such CERTIFICATE becomes void and it is discarded from trainer files.

Only qualified persons can be trained who then answer for performed works.

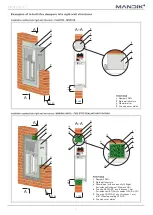

Damper must be installed with respecting of all safety standards and regulations.

Closing mechanism and blade seating faces must be protected from clogging to ensure reliable functioning of the damper.

Before putting the damper into operation serviceability checks and functional tests must be carried out including testing of

functionality of all electrical elements. After putting into operation these serviceability checks must be carried out 2 times a year

at least. If no defect is found during two subsequent serviceability checks, it is possible to carry out such operational checks once

a year.

If dampers are found as non-functional due to any reason, they must be clearly marked. User is obliged to ensure that the damper

is put in conditions in which it is able to fulfil its function and before this user must ensure fire protection in some other sufficient

way. Results of regular inspections and checks, found deficiencies and all important facts related to functioning of the damper

must be recorded in the FIRE JOURNAL and reported to user immediately.

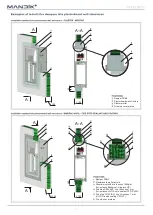

Before putting damper into serviceable condition after assembly and subsequent serviceability checks the following inspections

must be carried out:

■

Visual check of correct walling-in of the damper, thermal fuse, closing mechanisms and blade seating faces.

Functionality of closing mechanism is done as follows:

■

Press reset button on the thermo-electric actuator accessible through the hole in cover plate and check dislocation of blade

to the position "CLOSED" and signalling of positions "OPEN -CLOSED".

Serviceability checks of optical smoke detector are performed by manufacturer (LITES a.s. Liberec) or authorized company staff

with relevant electro-technical qualification and who were demonstrably trained by the manufacturer. Serviceability checks of

detectors are carried out within serviceability checks of fire dampers min. once a year.

Spare parts are supplied only on the basis of orders.

Содержание FDML

Страница 1: ......