Page 3

Version 2023-10-31

Fire damper - FDML

TPM 130/17

I. GENERAL

Working conditions

■

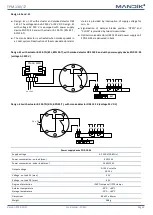

Exact damper function is provided under the following conditions:

■

maximum air velocity 12 m/s

■

maximum pressure difference 1500 Pa

■

Even distribution of air flow in complete damper cross section area

■

Damper operating characteristics are independent on airflow direction through the damper. The damper can be installed

with blade axis vertically or horizontally, temperature sensor (BAT) must always be in damper upper part.

■

Dampers are suitable for systems without abrasive, chemical and adhesive particles.

■

Dampers are designed for macroclimatic areas with mild climate according to EN IEC 60 721-3-3 ed.2., class 3K22.

(Environment 3K22 is typically protected place with regulated temperature).

■

Temperature in the place of installation is permitted to range from -30°C to +50°C.

■

Optical smoke detector ORS 142K with socket 143A is intended for environments protected from weathering of categories

3K5/3Z1/3Z8/3B1/3C2/3S1/3M2 within temperature scope -25°C to +70°C, max. relative humidity 95% at 40°C, without

condensing, icing and ice formation according to EN 60 721-3-3 amend.A2.

■

If the damper is used for self-ventilation it must be equipped with cover grilles from both sides.

Description

Fire dampers are shutters in ducts of air-conditioning devices

that prevent the spread of fire and combustion products from

one fire segment to the other one. FDML multi blade fire

dampers are in motorised design only with actuator and they

have the following two main applications:

For use as a fire shutter without following air duct with cover

grilles for closing ventilation openings in fire separating walls,

constructions, elevator and other shafts, cable and other

ducts, preventing the spread of heat and combustion

products.

For use as a multi blade fire damper with following air duct on

both sides (without cover grilles) or with duct on one side

(with one cover grille), preventing the spread of heat and

combustion products through this duct system.

Damper blades automatically closes air duct using a spring

return actuator. The return spring of the actuator is actuated

when a thermoelectric activation device BAT is activated,

when a test button on BAT is pressed or when power supply

of the actuator is interrupted.

After closing blades, the damper is sealed with silicon against

smoke penetration. On request by customer, the damper can

be supplied silicon-free. In the closed position, the damper is

also sealed with material which increases its volume due to

increasing temperature and air proofs the air duct.

Damper characteristics

■

CE certified acc. to EN 15650

■

Tested in accordance with EN 1366-2

■

Classified acc. to EN 13501-3+A1

■

Fire resistance EI 90 S, E 120 S

■

Leakage acc. to EN 1751, through the casing class B and

through the damper blades class 3

■

Cycling tests in class C

10000

acc. to EN 15650

■

Corrosion resistant acc. to EN 15650

■

Certificate of constancy of performance No. 1391-CPR-2020/0130/O1

■

Declaration of Perfomance No. PM/FDML/01/23/1

■

Hygienic assessment of fire dampers - Report No. 1.6/pos/19/19b