Fire damper - FDML

Page 16

Version 2023-10-31

TPM 130/17

■

The damper can be installed with blade axis vertically or

horizontally, temperature sensor (BAT) must always be in

damper upper part. The damper installation procedures

must be done so that all load transfer from the fire

separating constructions to the damper is absolutely

excluded. Following air-conditioning duct must be

suspended or supported so that all load transfer from the

following duct to the fire damper is absolutely excluded.

The gap between the installed damper and the fire

separating construction must be perfectly filled with

approved material.

■

During the installation and plastering process, the

actuating mechanism must be protected (covered)

against damage and pollution. The damper casing should

not be deformed during bricking in. Once the damper is

built in, the damper blades should not grind against the

damper casing during opening or closing.

■

The distance between the fire damper and the

construction (wall, ceiling) must be 75 mm at the

minimum, according to EN 1366-2. If two or more

dampers are to be installed in one fire separating

construction, the distance between adjacent dampers

must be 200 mm at the minimum, according to EN 1366-2.

■

Fire dampers can be installed without following duct on

one or both sides. In the case of this installation, the fire

dampers must be equipped with cover grilles.

■

For designs with an optical smoke detector, the best

conditions for detecting smoke and combustion products

must be ensured, i.e. the smoke detector must be located

at the upper part of the room.

■

It is recommended to install the dampers according to the

local disposition in such a way that the side of the damper

with the thermoelectric activation device is in line with

the wall and the opening on the other side of the wall is

permanently covered by a second cover grille fixed e.g. in

the frame. The minimum thickness of the standard wall

construction is 100 mm. In the case of an installation

where one side of the damper is in line with the surface of

the construction and the other side extends more than 25

mm from the construction, the extending part must be

covered with fire-resistant boards. In the case of

installation in a gypsum wall, the opening must be lined

with reinforcement profiles.

■

Dampers are not equipped with inspection openings. If

these dampers are used as dampers for simple mainte-

nance and revision they must be completed with connect-

ing inspection part installed just behind the damper.

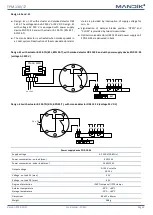

Minimum distance between the fire dampers and the construction

■

minimum distance 200 mm between dampers, according to EN 1366-2

■

minimum distance 75 mm between damper and construction (wall/ceiling), according to EN 1366-2

IV. INSTALLATION

Placement and installation

≥

75

≥

75

≥

7

5

≥

2

0

0

≥

7

5

≥

200

≥

200