7

8

9

Checking and repairing fuel injectors

35

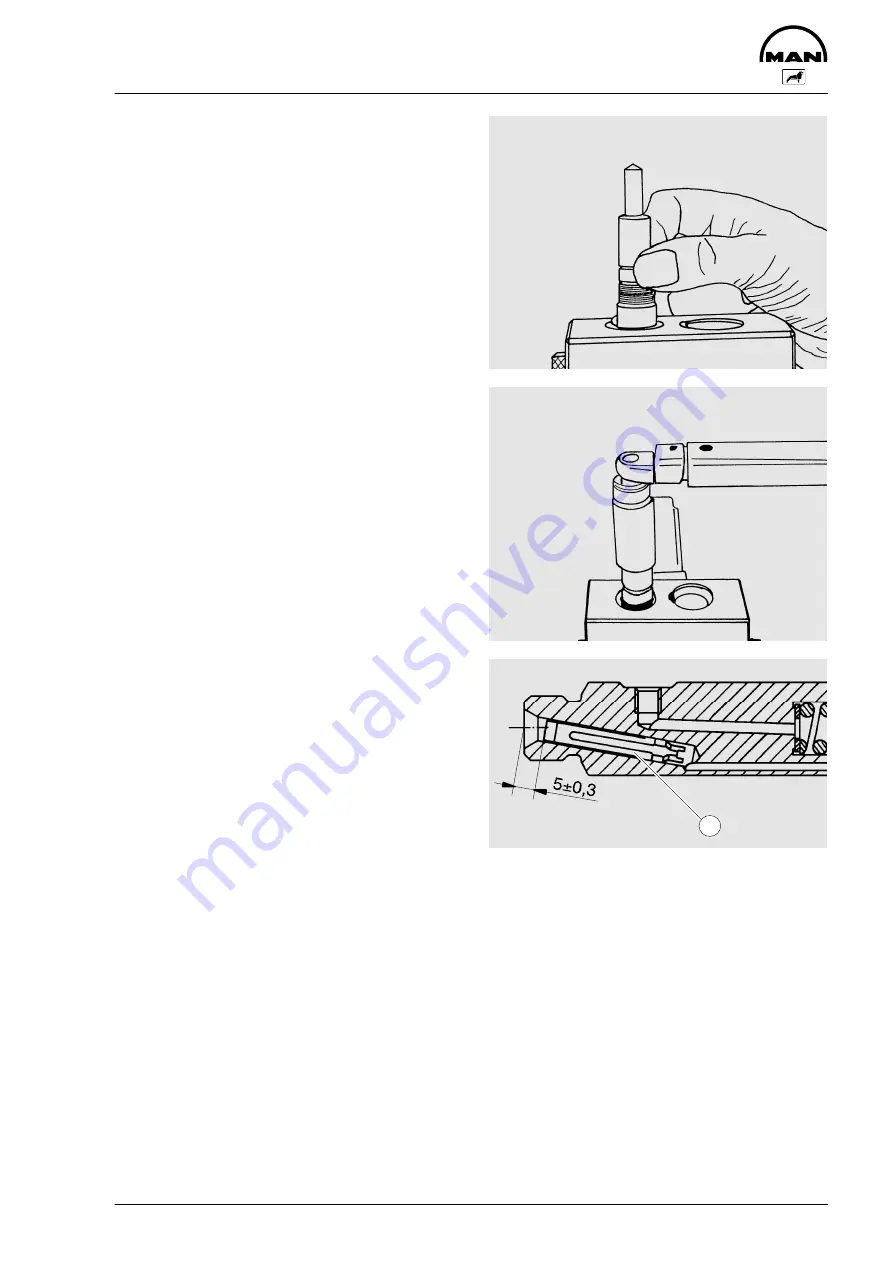

Fig. 7

Dip nozzle body and nozzle needle separately into

filtered Diesel fuel and check their gliding quality.

When pulled out of the nozzle body by up to a third

of its length the nozzle needle must sink back to its

seat under its own weight when released.

Place injection nozzle on top, ensuring that the

associated pins are correctly fitted.

Fig. 8

Screw on union nut, tightening it to the specified

torque (see “Service Data”).

Check injector on the manual test stand.

Ensure that the edge-type filter is correctly

seated in the injector body.

Fig. 9

A dislocated sieve bar filter

À

throttles and pro-

longs the injection and consequently causes poor

performance, high consumption and heavy smoke

formation in conjunction with heavy engine vibra-

tions.

For this reason measure the rim offset of the sieve

bar filter in the nozzle inlet.

The sieve bar filter must not be pressed into the

nozzle holder farther than approx 5 mm.

In the event of larger rim offsets, the nozzle holder

is to be replaced.

1

Содержание D 2866 LUE 605

Страница 1: ......

Страница 2: ......

Страница 14: ...Notes 12...

Страница 19: ...Memoranda 17...

Страница 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Страница 68: ...Memoranda 66...

Страница 133: ...131 Service Data...

Страница 157: ...155 Special tools...

Страница 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Страница 160: ...Special tools 158 10 11 16 14 14 1 12 13 18 18 1 12 1 12 2 15 5 15 4 15 1 15 1 15 2 15 3 15 3 15 6 15 7 15 17...

Страница 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Страница 164: ...Special tools 162 30 31 32 1 32 32 2...

Страница 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Страница 170: ...Notes 168...

Страница 173: ......

Страница 174: ......