[2] LUBRICATION

[3] DISASSEMBLY/ASSEMBLY

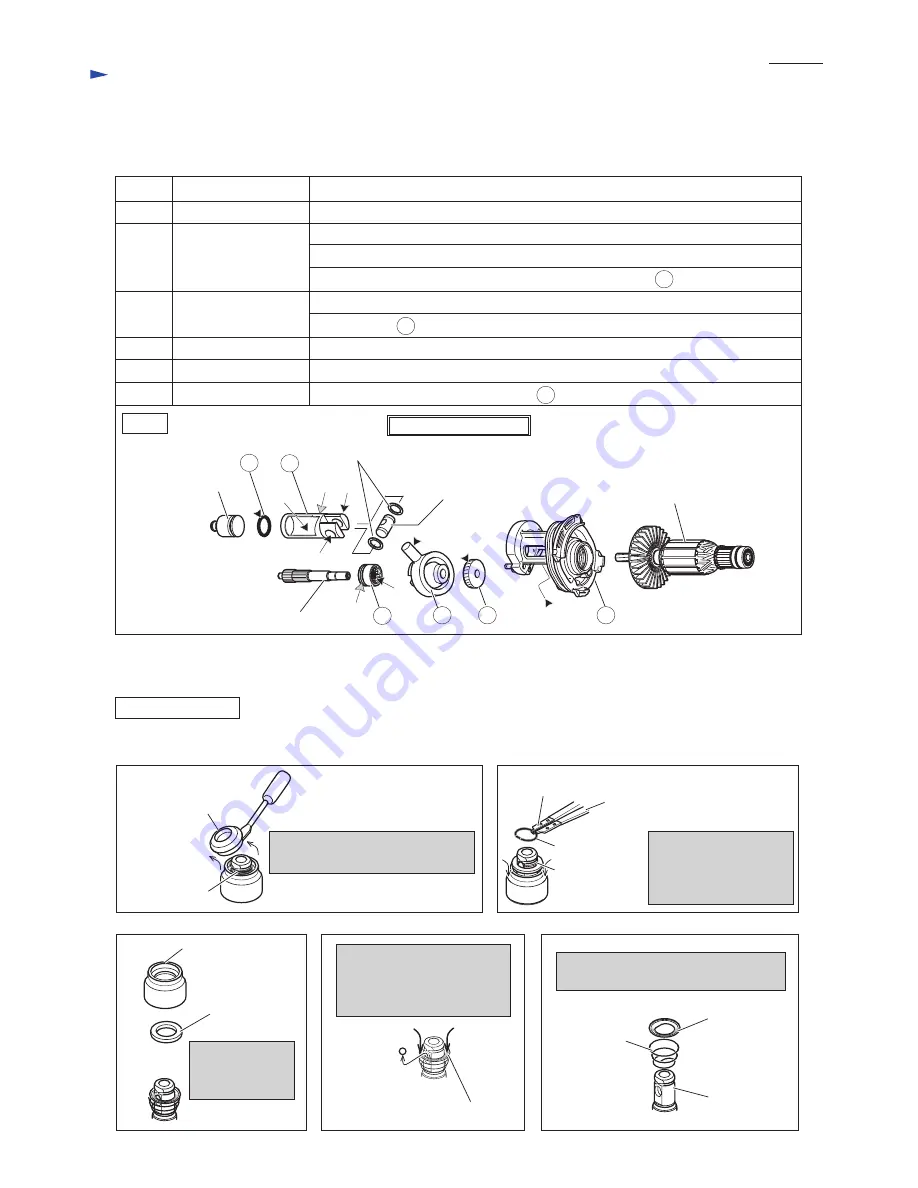

[3] -1. Chuck Section

Apply the following Makita grease to protect parts and product from unusual abrasion.

* Grease RB No.00 to the portions marked with black triangle

* Molybdenum disulfide lubricant to the portions marked with gray triangle

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

DISASSEMBLING

Item No.

Striker

Disassemble Chuck section in the order

from Fig. 3 to Fig. 7

.

Spur gear 10

Cap 35

Remove Ring spring 19

from the groove on Tool

holder complete using

1R003 and 1R212.

Pushing Guide washer in the

direction of arrow, remove

Steel ball 7.0 from the slot on

Tool holder complete.

Guide washer and Conical compression

spring 21-29 can be removed.

Chuck cover and

Ring 21 can be

removed.

Remove Cap 35 by hand and using

a slotted screwdriver.

Ring spring 19

Tool holder

complete

Ring spring 19

Piston joint

Armature

Flat washer 12

Swash Bearing Section

Description

Portion to lubricate

44

46

47

56

44

46

47

56

35

35

36

36

Clutch cam

Swash bearing 10

Helical gear 26

Inner housing cmplete

O ring 16

Piston cylinder

Whole portion

Pole portion which is inserted into Piston joint

Teeth portion

Space where Armature's drive end and 47 Helical gear 26 engages

(f) Inside where Striker moves

(g) Hole for accepting Piston joint

(h) Apply Molybdenum disulfide lubricant to Surface where 25 Tool holder contacts.

(f)

(g)

(h) (g)

(i)

(i) Apply Molybdenum disulfide lubricant to the groove.

(j)

(j) Side where 46 Swash bearing 10 engages

Chuck cover

Guide washer

Tool holder

complete

Conical

compression

spring 21-29

Ring 21

Steel ball 7.0

Guide washer

1R003

1R212

R

epair for 2 mode Rotary hammers HR2230, HR2460 and HR2460F

P

3

/

15