11 ENGLISH

8.

Never drop or throw the machine, unless an

emergency. If the machine drops or hits some-

thing, immediately check for fuel leakage,

safety devices and other damages.

Operating

a malfunctioned machine may cause injury and/or

fire.

9.

Inspect the cutting tool frequently, or immedi-

ately after it hits a stone or other hard objects.

If the cutting tool breaks during operation, the

broken piece may fly and cause injury.

10.

Stop the motor when inspecting, cleaning or

replacing the cutting tool.

Otherwise the cutting

tool may rotate unexpectedly and result in serious

injury.

11.

Maintain proper control until the cutting tool

stops completely, when stopping the motor or

releasing the throttle trigger.

A coasting blade

can cause injury.

12.

Before starting the cutting operation, wait until

the cutting tool attains enough speed for cut-

ting.

It reduces the risk of kickback and entangling

weeds.

13.

Take a rest to prevent loss of control caused

by fatigue.

We recommend taking a 10 to 20-min-

ute rest every hour.

14.

Stop the motor and place it in safe location,

when resting or leaving the machine.

It pre-

vents unexpected accident.

15.

Do not touch the engine and its muffler or do

not put them onto combustible materials, while

the engine runs or just after stopping it, as

they are hot.

Burn and/or fire may result.

Cutting Tools

1.

Use a suitable cutting tool for your work.

Always use the cutting tool guard properly

suited for the cutting tool used.

2.

Never use metal multi-piece pivoting chains,

flail blades or blades not recommended in this

manual.

Otherwise serious injury may result.

3.

When handling the metal blade, always wear

gloves and put the blade cover on the blade.

The blade can cut bare hands.

4.

When using metal blades, avoid “kickback”

and always prepare for an accidental kickback.

See the section

Kickback

.

5.

Before and after each operation, make sure

that the cutting tool is attached securely.

During operation, check the cutting tool for

looseness in certain intervals.

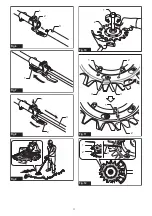

Kickback (blade thrust)

Kickback (blade thrust) may occur when the spin-

ning blade contacts an object that it does not imme-

diately cut. It can be violent enough to cause the

unit and/or operator to be propelled in any direc-

tion, and possibly lose control of the unit, resulting

in serious injury. Kickback can occur without warn-

ing if the blade snags, stalls or binds and is more

likely to occur in areas where it is difficult to see the

material being cut.

Kickback occurs particularly when applying the

blade segment between 11 and 1 o’clock to solids,

bushes and trees with 3 cm or larger diameter.

►

Fig.1

To avoid kickback:

1.

Apply the segment between 8 and 11 o’clock

and between 1 and 4 o'clock.

2.

Swing the tool evenly in half-circle from right

to left, like using a scythe.

This allows the

proper segment of blade to contact plants to be

cut.

3.

Never apply the segment between 11 and

1 o’clock.

►

Fig.2

4.

Never use cutting blades close to solids, such

as fences, walls, tree trunks and stones.

5.

Never use cutting blades vertically, for such

operations as edging and trimming hedges.

6.

Avoid using the tool in areas where it is diffi

-

cult to see the object being cut.

Vibration

Exposing to excessive vibration injures blood ves-

sels or nervous system of the operator and causes

the following symptoms in the fingers, hands or

wrists: “Falling asleep” (numbness), tingling, pain,

stabbing sensation, or alteration of skin color or

of the skin. If any of these symptoms occur, see a

physician.

To reduce the risk of “white finger disease”, keep

your hands warm during operation and well main-

tain the machine and accessories.

Maintenance

1.

Have your machine serviced by our authorized

service center using only identical replace-

ment parts. Use only identical spare parts and

accessories supplied by MAKITA.

Incorrect

repair and poor maintenance can shorten the life

of the machine and increase the risk of accidents.

2.

Never alter or remove any components of the

machine.

It may cause fire and/or serious injury.

3.

After use, clean the machine and check all

screws and nuts for tightness.

4.

Check the condition of the cutting tool, cutting

tool guard and shoulder harness. The cutting

blade must be sharp. Never straighten or weld

damaged cutting tools.

Other instructions

1.

Always store the machine in locked rooms and

with an emptied fuel tank.

2.

Pay attention to the environment. Avoid unnec-

essary throttle operation for less pollution

and noise emissions. Adjust the carburetor

correctly.

3.

Do not operate the engine with faulty exhaust

muffler.

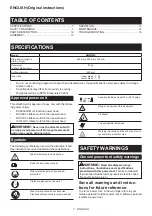

Содержание EM407MP

Страница 2: ...11 1 Fig 1 12 1 2 3 4 11 10 9 8 Fig 2 1 2 3 5 6 7 8 9 10 11 12 13 14 4 Fig 3 1 2 Fig 4 1 Fig 5 2 ...

Страница 3: ...1 2 3 Fig 6 1 Fig 7 Fig 12 3 1 2 Fig 8 Fig 9 1 2 Fig 10 1 1 2 2 3 4 Fig 11 1 2 3 Fig 12 3 ...

Страница 5: ...1 2 3 Fig 21 1 2 3 Fig 22 1 2 3 Fig 23 1 2 4 3 Fig 24 2 1 Fig 25 1 2 Fig 26 1 Fig 27 Fig 28 5 ...

Страница 6: ...1 Fig 29 Fig 30 6 ...

Страница 17: ...139 ...