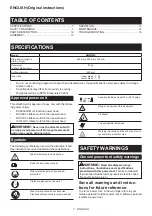

15 ENGLISH

NOTE:

To dismount the cutter blades, refer to the

section for dismounting the cutter blade.

Resharpening the cutter blades

CAUTION:

Always wear gloves when

resharpening the cutter blades.

NOTICE:

When resharpening the cutter blades,

sharpen both the upper and lower blade.

NOTICE:

If the cutter blades have considerably

deformed by filing, replace them with new ones.

NOTICE:

As a rough guide, sharpen the cutter

blades every 8 hours of use. Earlier resharpen-

ing is recommended if you often cut the weeds

together with their roots or cut the weeds on a

stony surface or a surface with a lot of obstacles.

Using dull cutter blades result in poor cutting perfor-

mance and damage to the machine.

NOTICE:

Use a diamond file for sharpening

cutter blades.

You can use a disc grinder instead.

1.

Dismount the cutter blades from the attachment.

NOTE:

Refer to the section for dismounting the cutter

blade for detail.

2.

Sharpen the tips and cutting edges of both upper

and lower blades at the angle of 40° using a file.

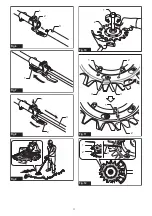

►

Fig.18:

1.

Cutting edge

2.

Tip

3.

Rib

4.

File

NOTE:

The upper blade should be replaced when the

teeth have been worn to the rib.

3.

Round the root of each blade as illustrated using

the file.

►

Fig.19

NOTICE:

Do not make the root of the blade

angled or chipped.

Doing so result in a crack in the

cutting blade.

Replacing the cutter blades

Optional accessory

CAUTION:

Always wear gloves when replac-

ing the cutter blades.

Before starting, make sure the direction of the upper

and lower blades; the cutting edges (angled surfaces)

on both upper and lower blade face outward each other

when assembled.

►

Fig.20:

1.

Cutting edge

2.

Lower blade

3.

Upper

blade

NOTICE:

If the cutting edges faces same side

or inward each other, you will not able to cut

grass.

Install the cutting blades by the following procedure:

1.

Dismount the old cutter blades from the

attachment.

NOTE:

Refer to the section for dismounting the cutter

blade for detail.

2.

Install a new upper blade onto the holder.

The upper blade has projection on one side. Be sure to

place the upper blade so that the projected side (arrow

marking printed) faces to the gear case.

►

Fig.21:

1.

Upper blade

2.

Gear case

3.

Projection

Align the oval holes in the upper blade with the pins.

Rotate the upper blade clockwise while pushing it down

until the pins hold the upper blade.

►

Fig.22:

1.

Upper blade

2.

Holder (for upper blade)

3.

Pin

NOTICE:

Be sure to position the upper blade so

that all pins hold the upper blade.

3.

Install a new lower blade onto the holder.

Place the lower blade so that the side with arrow mark-

ing faces to the holder and align the oval holes in the

blade with the pins. After that, rotate the lower blade

clockwise until the pins hold the lower blade.

►

Fig.23:

1.

Lower blade

2.

Holder (for lower blade)

3.

Pin

NOTICE:

Be sure to position the lower blade so

that all pins hold the lower blade.

4.

Put the lower blade (with the holder) onto the

upper blade while aligning the spline of the spindle with

that of the holder.

►

Fig.24:

1.

Lower blade

2.

Holder (for lower blade)

3.

Spindle

4.

Upper blade

5.

Place the clamp washer onto the holder while

aligning the spline of the spindle with that of the clamp

washer. After that, tighten the bolt by hand temporarily.

►

Fig.25:

1.

Bolt

2.

Clamp washer

6.

Align the holes in the lower and upper blades

and insert the hex wrench. After that, securely tighten

the bolt using the box wrench while the hex wrench is

inserted in the hole.

►

Fig.26:

1.

Box wrench

2.

Hex wrench

NOTE:

Refer to the section for dismounting the cutter

blades for how to align the holes of upper and lower

blades.

7.

Remove the hex wrench and then put the blade

cover onto the cutting blades.

Lubricating moving parts

NOTICE:

Follow the instruction of the fre-

quency and amount of grease supplied.

Otherwise

insufficient lubrication may damage moving parts.

Gear case:

CAUTION:

Do not apply grease when the

gear case is hot.

Hot gear case can cause burn

injury.

Remove the gear case access bolt using the box

wrench.

Apply grease (Shell Alvania 2 or equivalent) to the gear

case through the grease hole every around 50 working

hours.

►

Fig.27:

1.

Grease hole

Содержание EM407MP

Страница 2: ...11 1 Fig 1 12 1 2 3 4 11 10 9 8 Fig 2 1 2 3 5 6 7 8 9 10 11 12 13 14 4 Fig 3 1 2 Fig 4 1 Fig 5 2 ...

Страница 3: ...1 2 3 Fig 6 1 Fig 7 Fig 12 3 1 2 Fig 8 Fig 9 1 2 Fig 10 1 1 2 2 3 4 Fig 11 1 2 3 Fig 12 3 ...

Страница 5: ...1 2 3 Fig 21 1 2 3 Fig 22 1 2 3 Fig 23 1 2 4 3 Fig 24 2 1 Fig 25 1 2 Fig 26 1 Fig 27 Fig 28 5 ...

Страница 6: ...1 Fig 29 Fig 30 6 ...

Страница 17: ...139 ...